YMGI: Your Modern Green Idea

YMGI, Engineered Comfort Products for A Sustainable and Efficient Green World!

17

CEILING CASSETTE SYSTEMS - SPECIFICATIONS

Unit Specifications and Engineering

Submittal

System

WMMS-18KC-V2B(58)4 WMMS-24KC-V2B(58)4 WMMS-30KC-U2B(58)4 WMMS-36KC-U2B(58)4 WMMS-48KC-U2B(58)4

Power Supply

V/Ph/Hz

208-230 / 1 / 60

208-230 / 1 / 60

208-230 / 1 / 60

208-230 / 1 / 60

208-230 / 1 / 60

Power Voltage Allowed

Min./Max.

V

187 / 253

187 / 253

187 / 253

187 / 253

187 / 253

Surge Protector In Incoming

Power Supply

Field-

Install

Recommended

Recommended

Recommended

Recommended

Recommended

Cooling Capacity

Btu/h

17100

23800

28200

34000

48000

Capacity Range

Btu/h

5400-18700

8200-29000

8800-31400

10800-39000

20400-50500

Cooling Power Input Max.

W

1750

2500

3700

4500

5700

Heating Capacity @ 47 °F

Btu/h

18800

27200

31200

41000

54500

Heating Power Input

Min./Stand./Max.

Btu/h

4700-22200

8200-32400

8200-33600

9800-49500

17500-61500

Heating Power Input Max.

W

1900

2750

3500

4800

5400

Heating Capacity @ 17 °F

Btu/h

9900

15700

16700

23400

27600

SEER

16.0

16.0

20.0

18.0

16.0

EER

10.1

10.7

10.4

10.4

8.7

COP

W/W

2.7

3.4

3.7

3.2

3.3

HSPF

9.00

10.0

9.0

9.00

9.00

Gas Pipe Size

in.

1/2

5/8

5/8

5/8

5/8

Liquid Pipe Size

in.

1/4

3/8

3/8

3/8

3/8

Indoor Unit Model

WMMS-18EC-V2B(58)4 WMMS-24EC-V2B(58)4 WMMS-30EC-U2B(58)4 WMMS-36EC-U2B(58)4 WMMS-48EC-U2B(58)4

Air Flow Volume

CFM

353/445

510/765

587/880

730/1095

900 / 1350

Dehumidifying Volume

/hr

.85

1.14

1.42

1.61

2.13

Fan Motor Power Output

HP

1/5

1/5

1/5

1/3

1/7

Fan Motor FLA

A

0.5

0.5

0.9

0.9

1.5

Max. Over Current Protection

A

15

15

15

15

15

Min. Current (MCA)

A

1.0

1.0

1.5

1.5

2.0

Evaporator Form

Aluminum Fin-Copper

Tube

Aluminum Fin-Copper

Tube

Aluminum Fin-Copper

Tube

Aluminum Fin-Copper

Tube

Aluminum Fin-Copper

Tube

Set Temperature Range

°F

61-86

61-86

61-86

61-86

61-86

Sound Pressure Level

dB (A)

37/46

38 / 46

40 / 48

43 /49

41 / 53

Sound Power Level

dB (A)

37/46

38 / 46

40 / 48

43 / 49

41 / 53

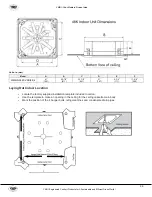

Indoor Unit Dimensions

in.

23.5 x 23.5 x 9.5

32.75 x 32.75 x 9.5

32.75 x 32.75 x 9.5

37.875 x 37.875 x

11.375

37.875 x 37.875 x 11.375

Outdoor Unit Model

WMMS-18C-V2B(58)4 WMMS-24C-V2B(58)4 WMMS-30C-U2B(58)4 WMMS-36C-U2B(58)4 WMMS-48C-U2B(58)4

Compressor Type

DC Inverter Driven

Rotary

DC Inverter Driven

Rotary

DC Inverter Driven

Rotary

DC Inverter Driven

Rotary

DC Inverter Driven Rotary

Compressor RLA

A

12.0

18.0

18.0

21.2

35.5

Fan Motor Power Output

HP

1/6

1/6

1/6

2/9

2 x 1/6

Fan Motor FLA

A

1.5

1.5

1.5

2.0

2 x 2.0

Max. Over Current Protection

A

25

40

40

45

70

Min. Current (MCA)

A

17.0

24.0

24.0

29.0

45.0

Outdoor Unit Air Flow Volume CFM

2590

2590

2590

2590

2590

Condenser Fin / Tube

Structure

Aluminum Fin-copper

Tube

Aluminum Fin-copper

Tube

Aluminum Fin-copper

Tube

Aluminum Fin-copper

Tube

Aluminum Fin-copper

Tube

Maximum Allowable Pressure PSIG

624

624

624

624

624