3. Cabling

3-2

TI 30A30A10-01EN

3.2

Connecting power cable

n

Power cables

Nominal conductor cross-section area: AWG10 (5.5 mm

2

equivalent) or more

Temperature rating of cables: Enclosure ambient tempe 35 ºC or more

Note: Use cables capable of supplying current required by respective pieces of equipment with low voltage drop.

Note: Ensure to secure the minimum bending radius of the cable. The minimum bending radius is either the value shown in the cable

manufacturer’s specifications or six-fold of the cable conductor diameter, whichever is bigger should be applied.

n

Power cable termination

l

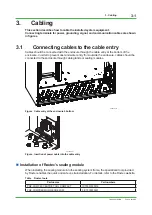

Solderless (crimp-on) lug terminal processing

Use solderless lugs for power cables (see Figure). Use solderless (crimp-on) terminals with

insulating cover, which have low contact resistance little aging.

F030201.ai

Insulation covering

inside diameter

Hole diameter

Lug outside

diameter

Lug length

Figure Solderless (crimp-on) lug

l

Solderless (crimp-on) lug specifications

The solderless lug to use must have the dimensions given in table according to the nominal cross

sectional area of the power cable for which the lug is to be used.

Crimping terminal: For round crimping terminal M5

Table Solderless lug dimensions

Nominal cross

sectional area

(mm

2

)

Screw used

(mm)

Hole diameter

(mm)

Lug outside

diameter

(mm)

Lug length

(mm)

Insulation

covering inside

diameter

(mm)

5.5

5 (*1)

5.3 or more

9.7 or less

approx.29

5.9 or more

*1:

Recommended tightening torque: 2.5 Nm to 3.0 Nm

CAUTION

• Always use solderless lugs with insulating covering.

• Always use solderless lugs and crimp-on tool manufactured by the same manufacturer.

• The crimp-on tool must be matched to the wire thickness.

Feb. 26, 2018-00