IM 01C22T01-01E

2-6

2. HART COMMUNICATOR OPERATION

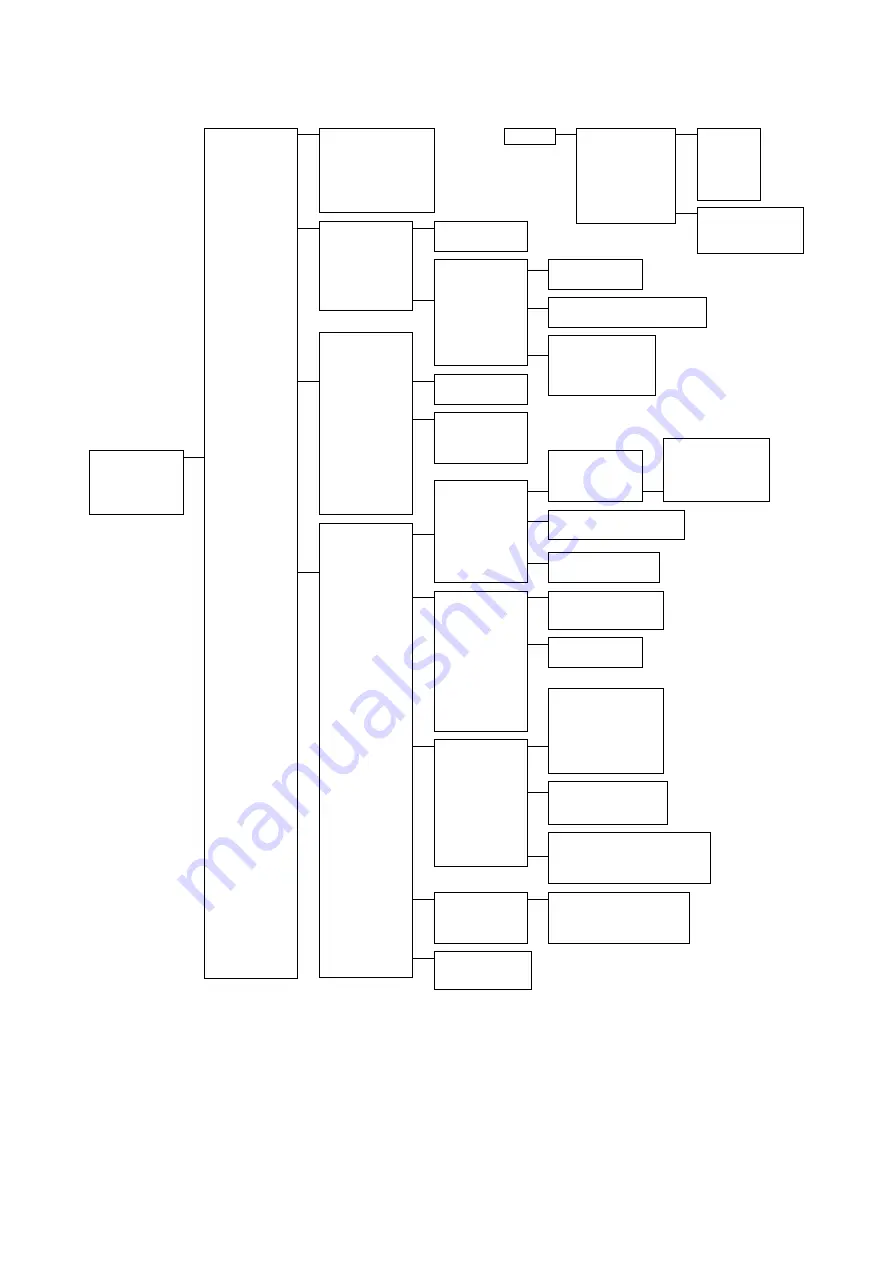

2.3.2 Menu Tree

1 DEVICE SETUP

2 Pres

3 A01 Out

4 LRV

5 URV

Online Menu

1 PROCESS

VARIABLES

2 DIAGNOSTICS

AND SERVICE

3 BASIC SETUP

4 DETAILED

SETUP

5 REVIEW

1 Pressure

2 Percent Range

3 Analog Output

4 Sensor Temperature

5 Static Pressure

6 Engineering Unit

7 Engineering Display

1 TEST/STATUS

2 Loop Test

3 CALIBRATION

1 Self Test

2 Status

1 Keypad Input

2 Wrt protect menu

Hot Key

1 LRV

2 URV

3 Unit

4 LSL

5 USL

6 Min Span

1 Tag

2 Unit

3 RERANGE

4 DEVICE INFO

5 Transfer Function

6 Damp

7 Low Cut

8 Cut Mode

1 Keypad Input

2 Apply Values

1 Date

2 Descriptor

3 Message

4 Write Protect

1 SENSORS

2 SIGNAL

CONDITION

3 OUTPUT

CONDITION

4 DISPLAY

CONDITION

5 DEVICE

INFORMATION

1 Pressure Sensor

2 Temperature

Sensor

3 Static Pressure

Sensor

1 Percent Range

2 Pressure

3 Unit

4 Sensor Trim

1 Zero Trim

2 Pressure

3 Lower Sensor Trim

4 Upper Sensor Trim

5 Sensor Trim Point

1 Sensor Temperature

2 Sensor Temperature Unit

1 Static Pressure

2 Static Pressure Unit

1 PROCESS

VARIABLES

2 RERANGE

3 Unit

4 Transfer Function

5 Damp

6 Low Cut

7 Cut Mode

8 Bi-dir Mode

9 H2O Unit Select

1 PROCESS

VARIABLES

2 ANALOG

OUTPUT

3 Analog Output

Alarm

4 HART OUTPUT

1 Display Mode

2 Display Function

3 Engineering

Display Range

1 Field Device Info

2 Sensor Info

3 Self Test

1 Engineering Unit

2 Engineering Display LRV

3 Engineering Display URV

4 Engineering Display Point

1 Pressure

2 Percent Range

3 Analog Output

4 Sensor Temperature

5 Static Pressure

6 Engineering Unit

7 Engineering Display

1 Loop Test

2 Digital-to-Analog Trim

3 Scaled D/A Trim

1 Poll Address

2 Number of Request Preambles

3 Burst Mode

4 Burst Option

1 Pressure

2 Percent Range

3 Sensor Temperature

1 Keypad Input

2 Apply Values

1 RERANGE

2 TRIM ANALOG

OUTPUT

3 SENSOR TRIM

1 Keypad Input

2 Apply Values

1 Digital-to-Analog Trim

2 Scaled Digital-to-Analog Trim

1 Zero Trim

2 Pressure

3 Lower Sensor Trim

4 Upper Sensor Trim

5 Sensor Trim Points

F0209.EPS

1 Write protect

2 Enable wrt 10 min

3 New password

4 Software seal