13-12

IM DR231-01E

13.5 Calibration

DISPLAY mode (to display and adjust the calibrated value)

Use this mode only for checking the calibrated value. In this mode, you can adjust the calibrated

value, but, if it is invalid, the instrument may be inoperative. For details, contact your nearest

Sales representative.

• Calibrated-value display items

• Calibrated-value display items vary depending on the type of module to be calibrated.

• For use with universal input modules, display calibrated-value display items in the following

order:

20 mV ZERO

→

20 mV SPAN

→

60 mV ZERO

→

60 mV SPAN

→

200 mV ZERO

→

200 mV SPAN

→

2 V ZERO

→

2 V SPAN

→

6 V ZERO

→

6 V SPAN

→

20 V ZERO

→

20 V SPAN

→

50 V ZERO

→

50 V SPAN

→

Pt: 1 mA ZERO

→

Pt: 1 mA SPAN

→

Pt: 2

mA ZERO

→

Pt: 2 mA SPAN

→

Pt: 1 mA-H SPAN

→

Pt: 2 mA-H SPAN

→

Cu: 2 mA

ZERO

→

Cu: 2 mA SPAN

• When the DC V/TC/DI input module is selected, the displayed values for RTD in the

universal input module can be modified without influencing operation of the recorder.

• The calibrated values appear in the above order each time the ENTER key is pressed. If the

MODE key is pressed while displaying calibrated values, the display returns to “A/D

calibration mode selection,” and the calibrated value already adjusted before pressing the

MODE key is canceled. Calibrated values are effective immediately after terminating the

DISPLAY mode.

• Adjustable range and error display

• Adjustable ranges are -32768 to 32767 (excepting 16384, -16384, 16385 and -16383).

• If the following numeric values are set, errors appear.

Outside the range from -32768 to 32767: ERROR002

16384 or -16384: ERROR145

16385 or -16383: ERROR144

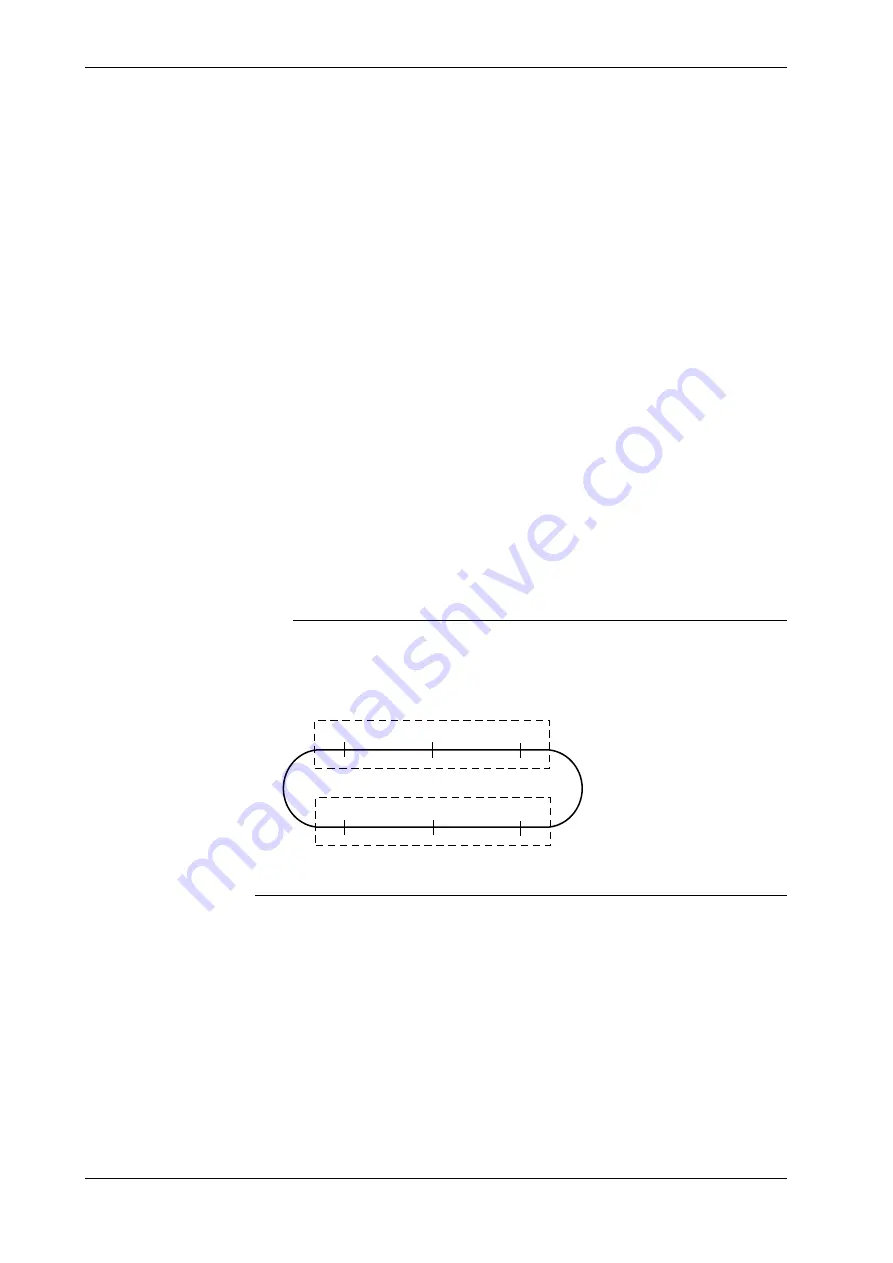

Note

• In the adjustable ranges, if the following are not satisfied, the adjusted module is recognized as an error

module.

• Calibrated value (ZERO) : -3277 to 3277 (ideal value = 0)

• Calibrated value (SPAN) : 29491 to -29491 (ideal value = -32768)

–29491

29491

–32768

ZERO calibration

SPAN calibration

–3277

0

3277

• When calibrating the DC, TC, or DI input module, you need not calibrate an RTD.

END mode (storing a calibrated value in the internal nonvolatile memory)

Select one of the following two:

• STORE : Stores data in the internal nonvolatile memory.

• ABORT : Cancels the storage of data in the internal nonvolatile memory.

Summary of Contents for DR231

Page 12: ...10 IM DR231 01E...