6-68

TI71M01D06-01EN 3rd Edition: 2012.12.01

6.4.3 Auto-tuning Operation

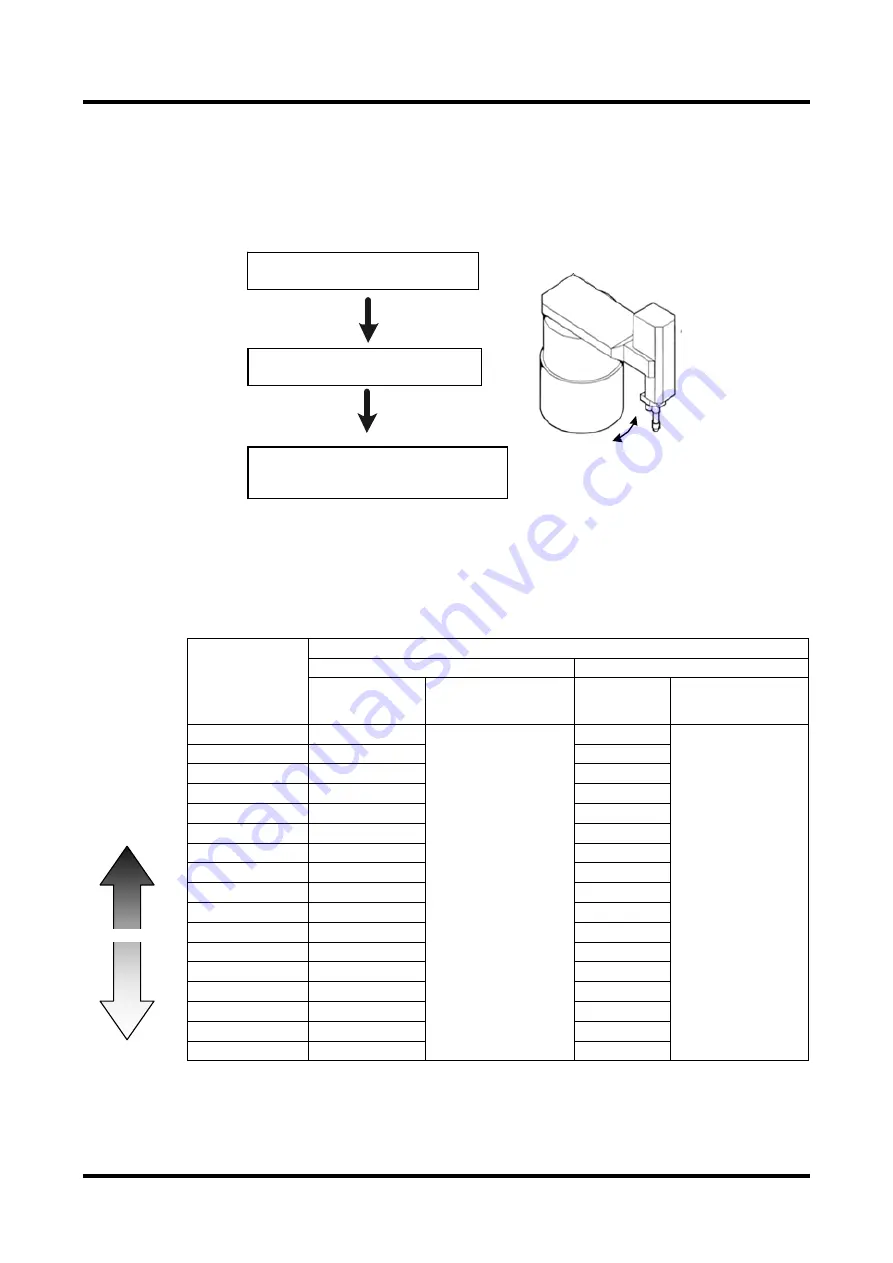

In order to tune the servo properly, it is necessary to register the load inertia in #0 [Load

inertia/Load mass]. When auto-tuning is performed, the load inertia is estimated and the

control # parameters are set automatically. Perform auto-tuning when starting up the system

and when the load inertia changes significantly.

#parameters Set Automatically by Auto-Tuning

The #parameters set automatically by auto-tuning vary depending on the specified control

mode, control method and states of IN_POSFREQ and IN_VELFREQ_SEL (see the table

below).

#parameters Set Automatically by Auto-Tuning

#1 [servo stiffness

setup]

#parameters automatically set by auto-tuning

Position control parameter (*1)

Velocity control parameter (*2)

Position control

bandwidth #8/#9

Position integral limiting

value #12/#13

Velocity control

bandwidth

#2/#3

Velocity integral limiting

value #6/#7(*3)

13 39

A value that specifies the

maximum torque that may

be output by the integrator

in the controller to remove

a small position deviation

(the value changes

depending on the motor

model, load inertia and

servo rigidity setting

value).

150

A value that specifies

the maximum torque

that may be output by

the integrator in the

controller to remove a

small velocity deviation

(the value changes

depending on the motor

model, load inertia and

servo rigidity setting

value).

12

38 140

11 36

130

10 34

120

9

32 110

8 30

100

7

28 90

6 26

80

5 24

70

4 22

60

3

19 50

2 16

40

1 14

30

0 9

20

-1 8

15

-2

6 12

-3 5

10

*1

Set to #8and #12 if IN_POSFREQ_SEL is OFF and to #9 and #13 if it is ON.

*2

Set to #2 and #6 if IN_VELFREQ_SEL is OFF and to #3 and #7 if it is ON.

*3

Set only when the velocity control method is set to proportional integral control in

system setup register 1 (0 is set in the case of proportional control).

The motor reciprocates several times and

the lord inertia is estimated

The estimated load inertia is automatically

set in #0

The control #parameters corresponding to

#1 [Servo stiffness setup] (see the table below)

are set automatically.

Position feed forward,

velocity feed forward,

acceleration feed forward

and various filters

are not adjusted

Servo stiffness

(response)

Lower

Higher

Default setting