2-16

TI71M01D06-01EN 3rd Edition: 2012.12.01

•

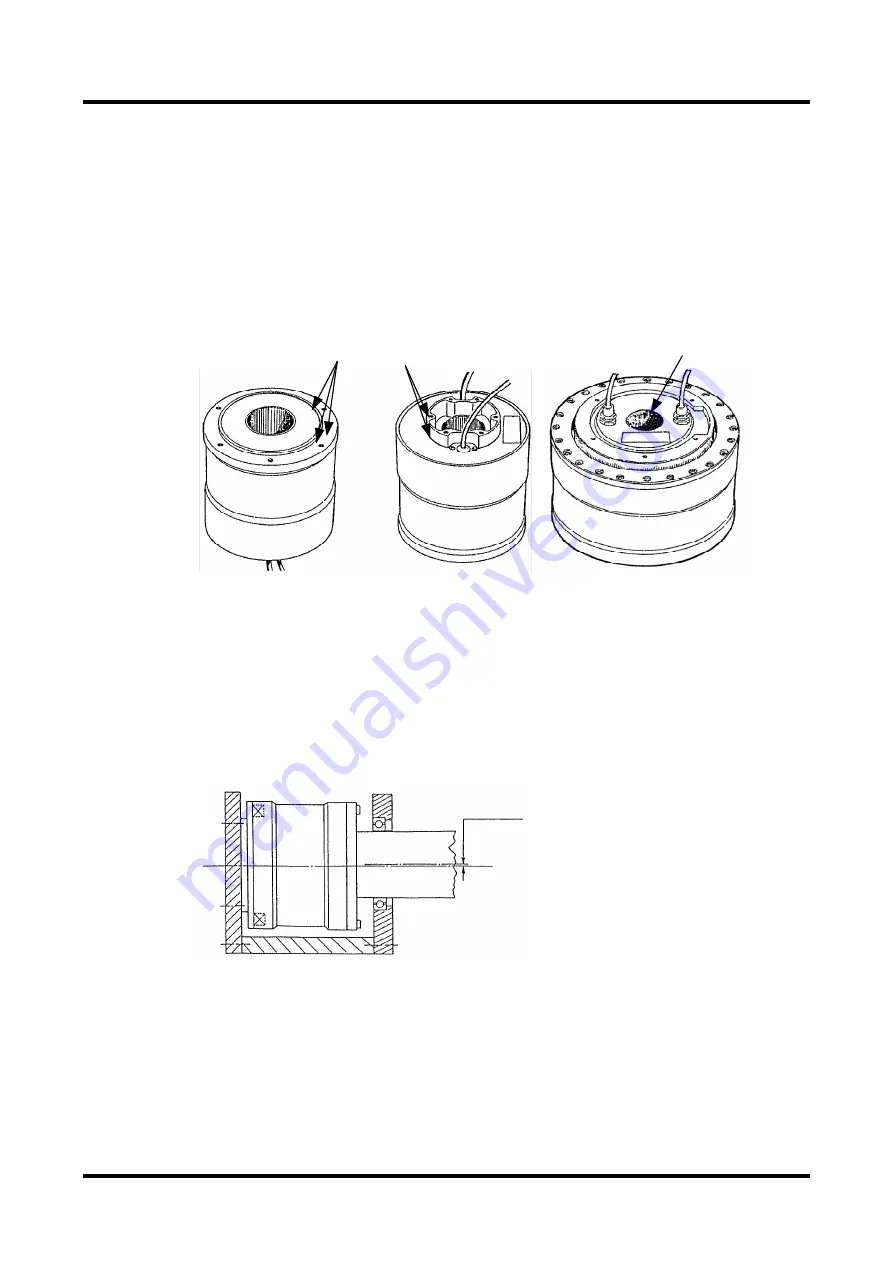

When you lead an object through the hollow hole, make sure to allow for a clearance of

1mm or more on all sides so the object and the internal surface of the hollow hole are not

in contact. Never press an object into the hollow hole or apply force to it. The precision

and functions of the motor may be impaired, causing failure.

•

For the DR motors, the load mounting surface on the upper surface and the stator at the

bottom surface are coated to prevent rust. When installing the product, wipe away the

coating completely using organic solvent (e.g. thinner, hydrocarbon solvent). If any

coating remains, the precision and functions of the motor may be impaired. Prevent

areas other than the load mounting surface and the stator, such as cables and internal

parts of the motor, from being subjected to the solvent and the left-over coating.

•

Be careful that the load mounting and motor mounting screws do not reach or exceed the

allowable screw depth length on the motor. Depending on the model used, the

functionality of the motor may be impaired and failures may occur if the screws reach or

exceed the maximum depth of the screw hole.

•

When connecting the motor and load, make sure to align the centers of the rotating parts

sufficiently and mount the load with a precision of 0.01mm or less. If the centering

precision is insufficient, abnormal noise and vibration may be generated and the bearing

inside the motor may be damaged.

Hollow hole

Surfaces where anti rust coating is applied

Centering precision: Within 0.01 mm