v

TI 71M01D06-01EN 3rd Edition: 2012.12.01

•

If you intend to use the motor in applications where the move is sliding/rotating at a

small angle (50

°

or less), it is necessary to perform a reciprocating move (rotate the

motor 180

°

from the operational range of motion) of 90

°

or more approximately 10 times

for every 10,000 cycles of the small-angle move in order to prevent the bearing

lubrication from becoming insufficient.

•

The motor's surface is magnetized. Keep objects that are affected by magnetism away

from the motor.

•

The motor and drive structures are not resistant to dust, splash or water (oil).

Therefore, choose the installation environment carefully.

•

The drive should be installed on an appropriate metal cabinet, observing the safety

measures prescribed by the Low Voltage Directive and EMC Directives.

•

Interchangeability between motors and drives is only possible if the drive and motor

are compatible (not every motor can be connected to every drive). To determine

compatibility, the DYNASERV motor's five digit model and suffix code must match the

drive's five digit model and suffix code. For example, using

to represent the model

and suffix code values, the motor's five digit model and suffix code (DM

-

or

DR

-

) must match the drive's model and suffix code (UD

G3-

or

UR

G3

), respectively. In addition, the current of the drive must also match the

motor requirements.

•

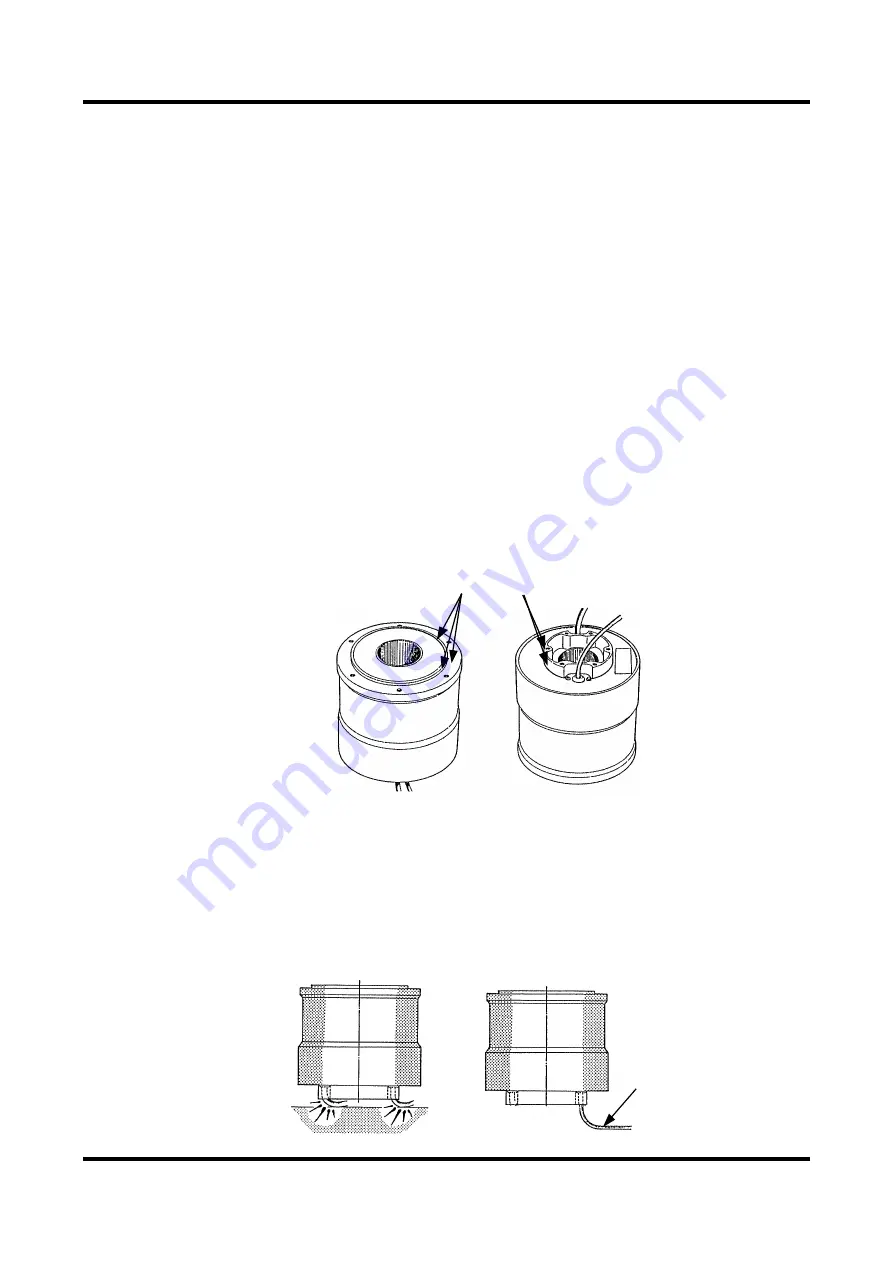

The load mounting surface on the motor's upper surface and the stator's mounting

surface at the bottom surface are coated to prevent rust. Before assembling and using

the product, wipe the coating off completely. If any coating remains, the mechanical

precision may be impaired. Be careful so that the coating material and cleaning

solution do not penetrate the motor. If so, the product's internal parts may be

damaged.

•

Do not place the motor in the manner shown below. Cables may be flattened and

ultimately disconnected due to the weight of the motor. If you install the motor with the

cable connections below the motor, be sure to include a structure that supports the

cables to avoid any potential damage.

•

If the product is installed in such a way that cables are bent in the machine, etc., be

sure the minimum bend radius of the cable is 50mm or more. Moreover, do not install

cables such that they are bent repeatedly. It may cause disconnection and failure.

Standard and optional cables provided by us are limited life-time article and

consumption goods.

Surfaces where an anti-rust coating is applied

The minimum bending radius

must be 50 mm or more.