IM 77J04H31-01E 4th Edition

Oct. 15, 2019-00

2

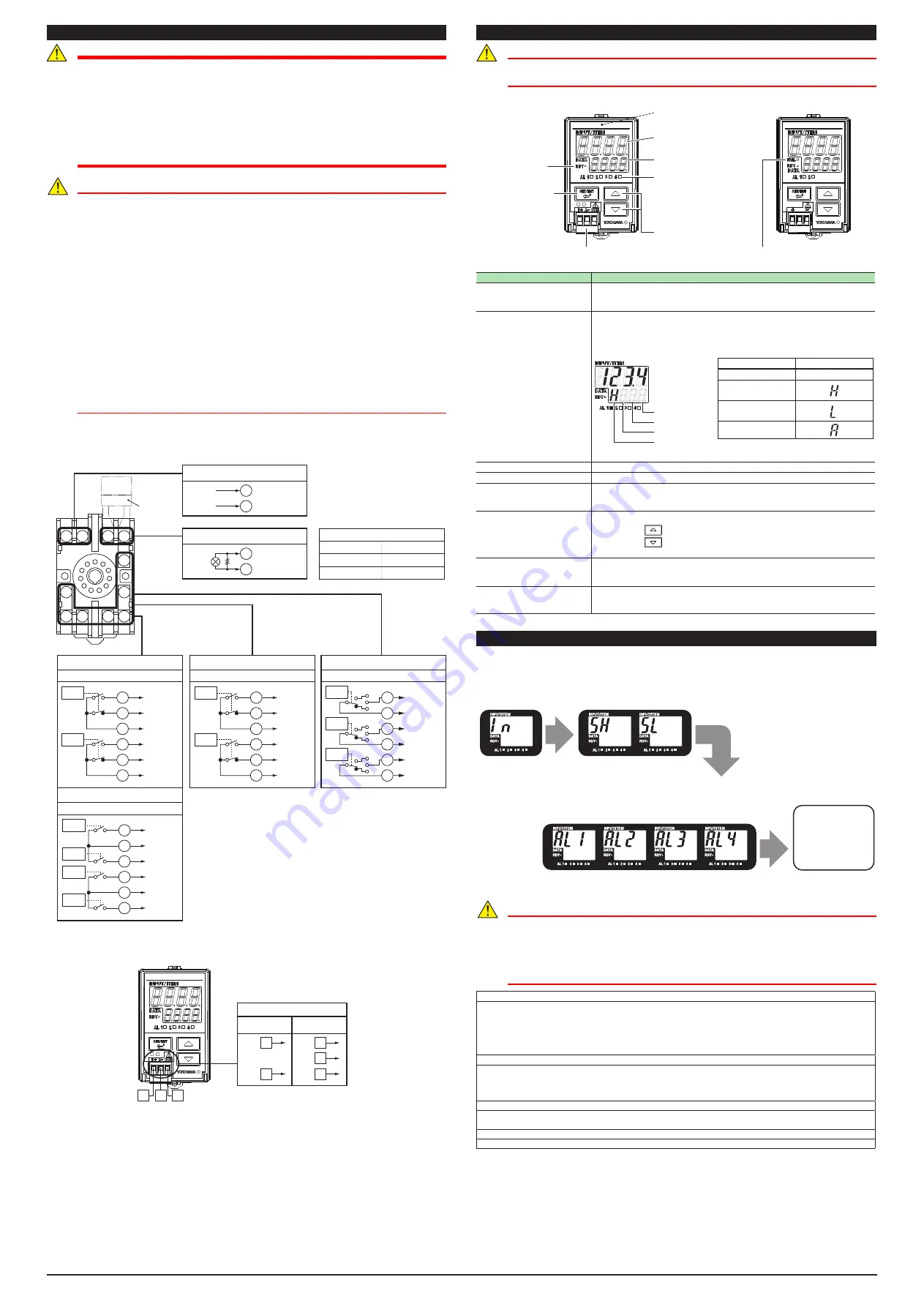

4. EXTERNAL WIRING

WARNING

●

To avoid the risk of an electric shock, turn off the power supply and use a tester or

similar device to ensure that no power is supplied to a cable to be connected, before

carrying out wiring work.

●

Do not operate the product in the presence of flammable or explosive gases or

vapors. To do so is highly dangerous.

●

Use of the product ignoring the specifications may cause overheating or damage.

Before turning on the power, ensure the following:

•

Power supply voltage and input signal value applied to the product should meet the

required specifications.

•

The external wiring to the terminals and wiring to ground are as specifications.

CAUTION

●

The power line and input/output signal lines should be installed away from noise-

generating sources. Otherwise accuracy cannot be guaranteed.

●

The product is sensitive to static electricity; exercise care in operating it. Before you

operate the product, touch a nearby metal part to discharge static electricity.

●

If an inductance (L) load such as auxiliary relays or solenoid valves is used, always

insert a spark killer for diminishing sparks, such as a CR filter or a diode in parallel

with the inductance load. Otherwise a malfunction or relay failure may occur. Refer to

the following guidelines for a capacitor and resistor:

Capacitor: 0.5 to 1 µF with respect to a contact current of 1 A

Resistor: 0.5 to 1 Ω with respect to a contact voltage of 1 V

●

Transfer contacts for 2 points of alarms consist of an NO contact and an NC contact.

When using transfer contacts, consideration should be given to the risk of a short

circuit due to contact MBB

*1

resulting from non-concurrent action of the NO and NC

contacts or to a short circuit caused by arcs produced when opening a contact at

large current.

*1 The condition where both NO and NC contacts close when the contact actuates

●

Fail output of the fail output type is energized during normal operation and de-

energized on FAIL (same as when the power is turned off).

•

When NO is specified: The contact opens when it is FAIL.

•

When NC is specified: The contact closes when it is FAIL.

●

Do not connect anything to the terminals that are not used in the wiring diagram.

Wiring should be connected to the terminals on the socket of the MVHK. The terminals for external

connections are of M3.5 screws. Use crimp-on lugs for connections to the terminals.

It is recommended that signal wires have a nominal cross-sectional area of 0.5 mm

2

or thicker, while

the power cable has a nominal cross-sectional area of 1.25 mm

2

or thicker.

10 11

1 2

3

9

8 7

6 5

4

5

6

R

–

+

10

11

9

2

3

1

(IN)

10

9

11

2

1

3

7

8

N–

L+

(SUPPLY)

1

2

3

10

11

4

NO

NC

NO

NC

NO

NC

1

2

10

11

3

4

Resistance value

100

Ω

250

Ω

Part number

RES-100

RES-250

MVHK-00

[]

-

[]

1

[]

0

MVHK-00

[]

-

[]

2

[]

0

NO

NC

COM

NO

NC

COM

NO

COM

NO

NO

COM

NO

MVHK-10

[]

-

[]

1

[]

0

NO

NC

COM

COM

COM

COM

NO

NC

COM

Relay

Relay

Relay

Relay

Relay

Relay

Relay

Relay

MVHK-20

[]

-

[]

3

[]

0/F

[]

Alarm 1

(ALM1)

Alarm 1

(ALM1)

*

*

*

Alarm 2

(ALM2)

Alarm 2

(ALM2)

Alarm 1

(ALM1)

Alarm 1

(ALM1)

Alarm 4

(ALM4)

Alarm 2

(ALM2)

Alarm 3

(ALM3)

Alarm 2

(ALM2)

Fail output

(FAIL)

Relay

Relay

Relay

* The setting of NC or NO

depends on the optional

specifications at the time of

order. This setting can not be

changed after delivery.

Input signal

Power supply

Receiving

resistor

Receiving resistor

R: 100 Ω or 250 Ω, externally connected for current input

2 points of alarm outputs

Fail output type

4 points of alarm outputs

2 points of alarm outputs (JK12 type)

Wiring for Monitor Output

If the monitor output code (one of 6, A or P) is specified at the time of order, the following wiring is

possible.

A–

COM

B+

–

+

1

1

3

1

2

3

2 3

Monitor output

Analog output

RS-485

communication

5. PART NAMES OF FRONT PANEL AND THEIR FUNCTIONS

CAUTION

The front panel of the product is constructed to prevent opening. Forcing it open will

result in breakage.

Fail output type

(1) PV (measured value)

display

Place for adhering

the tag number label

(2) DATA display

(3) Alarm indicator lamp

2 points of alarms:

2 lamps

4 points of alarms:

4 lamps

(7) Monitor output terminal (option)

(8) Fail indicator lamp

(6) UP/DOWN key

(5) SET/ENT

key

(4) READY

lamp

Part Name

Function

(1) PV (measured value)

display

Displays a measured value during operation.

Displays a parameter symbol when a parameter is set.

Displays an error code in the event of an error.

(2)

DATA display

Displays the setpoint of a variety of parameters.

Displays an alarm type in the event of an alarm. (Not displayed during

normal operation.)

• Alarm display (when alarm 1 is the PV high-limit alarm)

Alarm-1

Alarm-2

Alarm-3 *

Alarm-4 *

Display position

of alarm action

type

Alarm action

Alarm action type

No alarm (normal)

None

PV high limit

alarm

PV low limit

alarm

Other alarms

*Alarm-3 and Alarm-4 are 4 points alarm only.

(3)

Alarm indicator lamp

In the event of an alarm, AL1 to AL4 (alarm 1 to alarm 4) light up.

(4)

READY lamp

Lights up when the power is turned on.

(5) SET/ENT key

Used to switch parameter indication or accept a setpoint.

Pressing this key for more than 3 seconds allows you to select the

Operation Parameter Screen and Setup Parameter Screen alternately.

(6) UP/DOWN key

Used to change the setpoint of a parameter.

Pressing the

key increases a numerical value.

Pressing the

key decreases a numerical value.

Holding down a key accelerates the speed of change.

(7)

Monitor output terminal

(Two-piece connector)

Outputs 1 to 5 V DC, 4 to 20 mA DC or RS-485 communication signal.

(To be added only when the monitor output has been specified at the

time of order.)

(8)

Fail indicator lamp

Lights up in a fault condition. The self-diagnosis function detects the Fail status *.

* EEP sum error, EEP error, AD error, ROM error, RAM error

(When type code 2 is specified when ordering.)

6. PARAMETER SETTING ORDER AND PRECAUTIONS

When setting a parameter, begin with Step 1 below and continue in sequence.

Range code No.

(IN)

Max./min. input scaling values

(SH) (SL)

You can enter either parameter first.

You can begin with any of these parameters.

Alarm-1 action

Alarm-2 action

Alarm-3 action

Alarm-4 action

(AL1) (AL2) (AL3) (AL4)

After that, you may

proceed with

settings beginning

at any parameter.

Step 2

Step 3

Step 1

CAUTION

●

If the settings for the range code No. (IN), maximum and minimum input scaling

values (SH)/(SL) or alarm actions (AL1 to AL4) are changed, the relevant parameter

setpoints shown in the table below will be initialized. To change a parameter setpoint,

begin with Step 1 above and continue in sequence.

●

Do not turn off the power of this product while changing the parameters of this

product or adjusting this product.

Parameters to be initialized if the range code No. (IN) is changed

Max. and min. measured input values (RH, RL), decimal point position of scaling value (SDP), max. and min. input

scaling values (SH, SL)

Alarm setpoints (A1 to A4), hysteresis (HY1 to HY4), setpoint (SP)

Max. and min. monitor output values (RTH, RTL)

Input adjustment point LOW (BL) and HIGH (BH), input adjustment LOW (AL) and HIGH (AH)

High and low limits for PV display color change (PCH, PCL)

Parameters to be initialized if the maximum or minimum input scaling value (SH) or (SL) is changed

Alarm setpoints (A1 to A4), hysteresis (HY1 to HY4), setpoint (SP)

Max. and min. monitor output values (RTH, RTL)

Input adjustment point LOW (BL) and HIGH (BH), input adjustment LOW (AL) and HIGH (AH)

High and low limits for PV display color change (PCH, PCL)

Parameters to be initialized if the type of alarm action (AL1 to AL4) is changed

The alarm setpoint (A1 to A4) corresponding to each alarm action (AL1 to AL4)

(Example: If AL1 is changed, A1 will be initialized.)

Parameters to be initialized if the type of PV display color mode (PCM) is changed

High and low limits for PV display color change (PCH, PCL)