< 1. Specifications

>

1-4

IM 12B07N01-01E

1.2.2

Flow-Through Type Holder (Explosionproof Type)

PH8HFF

[Style: S2]

Model

Suffix Code

Option Code

Description

PH8HFF

................................................. ................

Flow-through type holder

Material (*7)

-PP

-S3

................

................

Polypropylene (Refer to note below for selection)

Stainless steel

Process Connection

-JPT

-NPT

-J10

-A15

................

................

................

................

Rc1

1 NPT female thread

JIS 10K 25 FF flange

ANSI Class 150 1 FF flange equivalent (for polypropylene holder -PP)

ANSI Class 150 1 RF Flange with serration (for SUS316 holder -S3)

pH Measuring System

-T

................

Always -T

Cleaning System (*4)

(Ultrasonic cleaning only)

-S3

-TN

-HC

................

................

................

(SUS316 transducer) (*1)

(Titanium transducer) (*2)

(Hastelloy C transducer) (*3)

Explosion Protection

-JS

................

TIIS Flameproof (d2G4)

Style Code

*A

...................

Style A

Option

Special Mounting

Flameproof Packing

Tag Plate

O-ring

/MF1

/PG2

/SCT

/PF

Mounting bracket (stainless steel) (*6)

JIS flameproof packing adapter 3/4 inch

Stainless steel tag plate

Perfluoroelastomer (FFKM) (*5)

*1:

General purpose (Normal pH 3 to 14)

*2:

For salt water

*3:

For acid (Normal pH 0 to 4)

*4:

Use PH8HS for no cleaning, Jet cleaning or Brush cleaning.

*5:

Choose Perfluoroelastomer (FFKM) when this holder is used in organic solvent, high alkali or high temperature alkali.

*6:

Mounting bracket is generally not required when the stainless steel holder is installed in-line in a pipe

It is required where the holder is installed in a sampling rack (in which case the U-bolt included in /MF1 in not used).

*7:

Criteria for material selection (-PP or -S3)

In general, polypropylene is recommended from the viewpoint of chemical resistance.

However stainless steel is recommend in any of the following cases:

• The liquid contains organic reagent, oxidizing agents, etc., which can attack polypropylene.

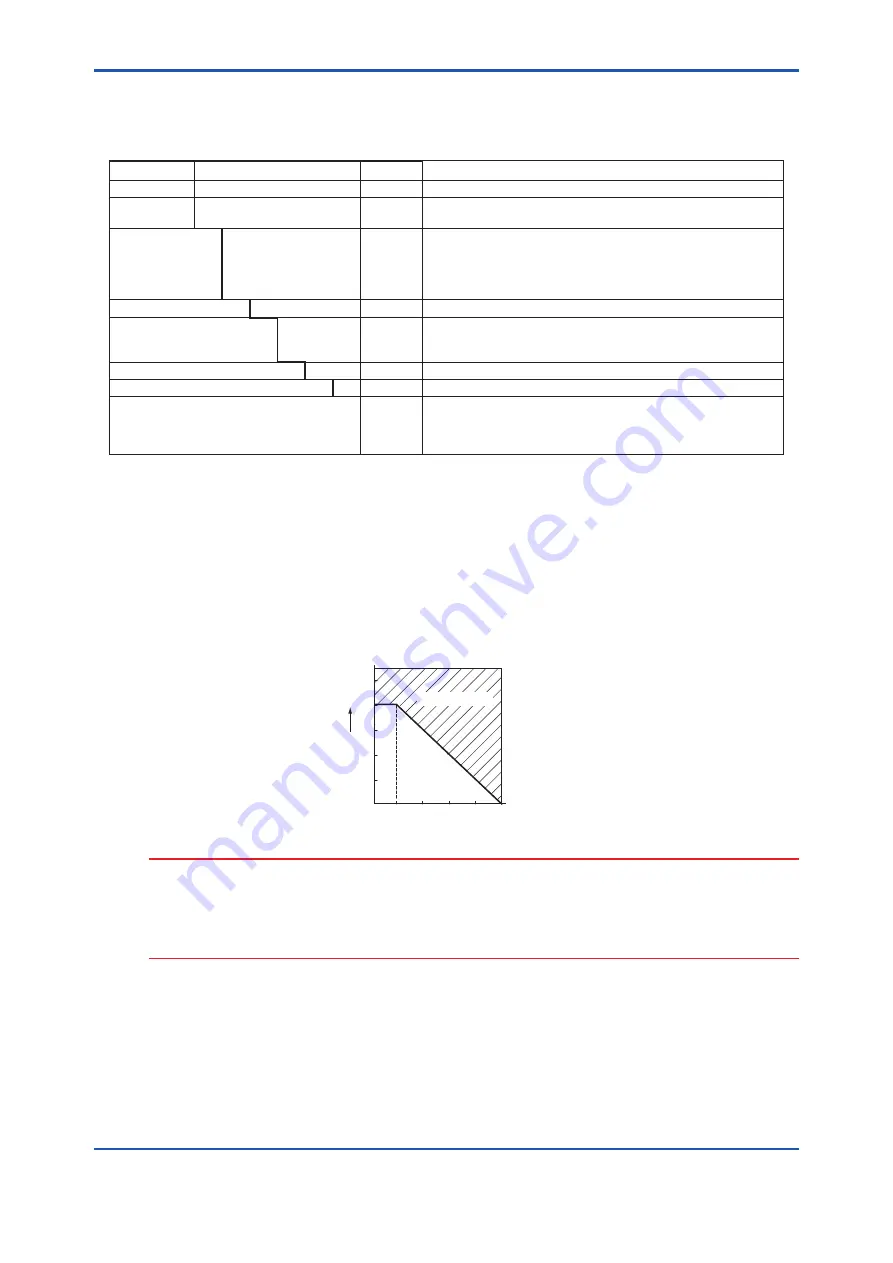

• The temperature/pressure correlation of the process condition falls within the hatched area of the diagram shown right.

• The use of polypropylene is not reasonable from a viewpoint of strength or past experience.

For stainless steel, normally a 3 to 14 pH value is recommended.

CAUTION

Select the material of wetted parts with careful consideration of process characteristics.

Inappropriate selection may cause leakage of process fluids, which greatly affects facilities.

Considerable care must be taken particularly in the case of strongly corrosive process fluid such

as hydrochloric acid, sulfuric acid, hydrogen sulfide, and sodium hypochlorite. If you have any

questions about the wetted part construction of the product, be sure to contact Yokogawa.

0 100

105

100

80

60

40

20

Polypropylene

(or Stainless Steel)

200 300

Pressure (kPa)

400 500

Stainless Steel

Temperature

(°C)