< 2. Installation, Piping and Wiring >

2-5

IM 12B07N01-01E

F2.9E.ai

Flowmeter

Stop Valve

Stop Valve

Process Piping

Cleaning Piping

Drain Piping

Check

Valve

Stop

Valve

Solenoid

Valve

Stop

Valve

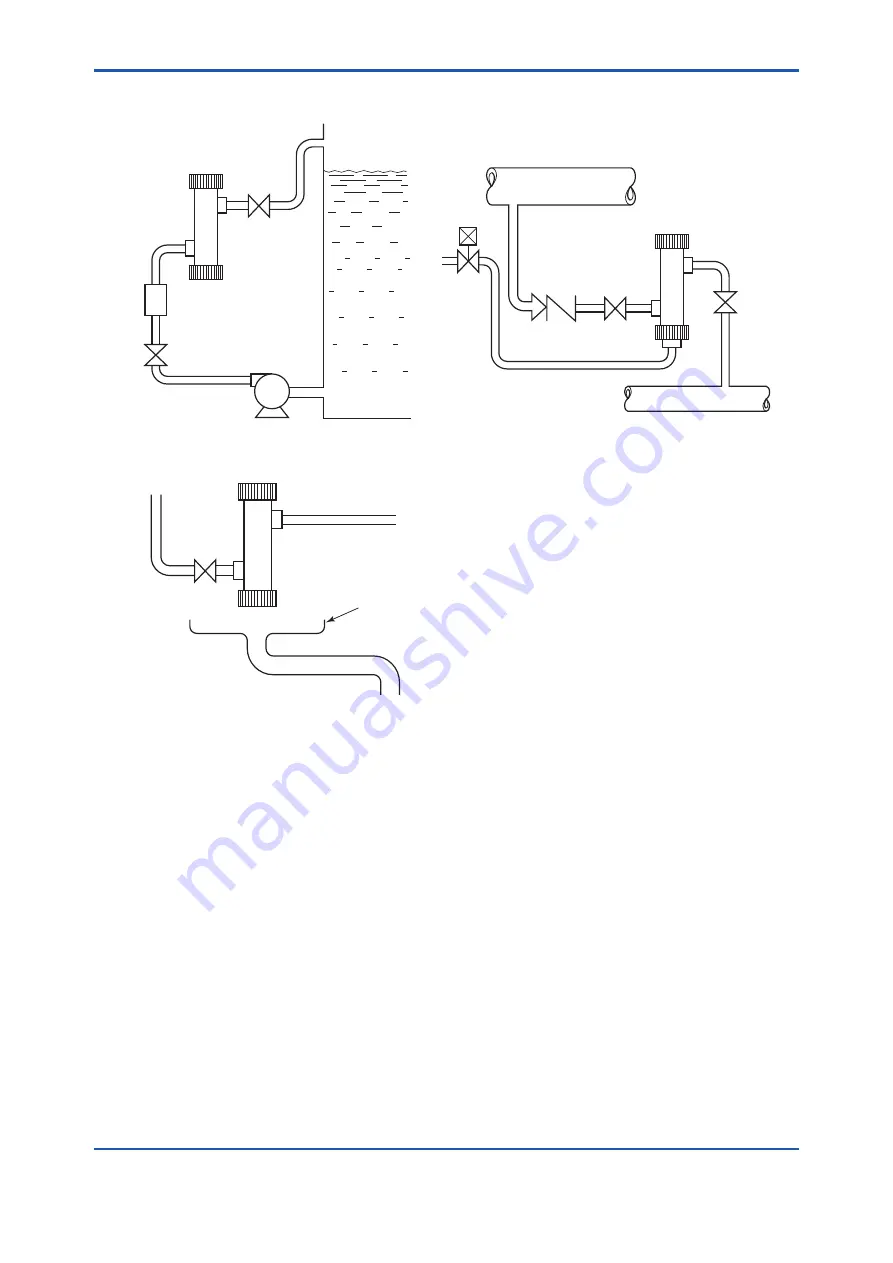

1. Install stop valves upstream and downstream of the

flow-through holder to allow ease of maintenance.

2. Install a check valve before the flow-through holder

as necessary.

Figure 2.9

When the Solution has a Pressure

Flow-Through Holder

Drain Pan

F2.10E.ai

Figure 2.10

Cleaning the Flow-Through Holder

2.3

Installing the Sensor

Refer to the separate manual describing the sensor to be used.

2.4

Cleaner Piping

This section applies only to the submersion type holder with cleaner.

2.4.1

Piping Precautions

(1) Provide a slight slack in a flexible tubing between the cleaner and a mating device to allow

ease of maintenance.

(2) Determine the cleaner pipe size to allow sufficient flow and pressure. Use nominal 15

mm pipe for air cleaning piping. If the water/jet cleaner pipe or water/brush cleaner pipe is

subject to freezing temperature during winter, cover it with a suitable insulation material.

(3) Use a normally-open (opens when relay is energized) nominal 15 mm diameter solenoid

valve for the cleaning line. The solenoid valve supplied by Yokogawa meets the following

specifications.