2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6793

http://www.yokogawa.com/ns/ut/im/

You can download the latest manuals from the following website:

User’s

Manual

• Authorised Representative in the EEA

Yokogawa Europe BV. (Address: Euroweg 2 , 3825 HD Amersfoort, The Netherlands) is

the Authorised Representative of Yokogawa Electric Corporation for this Product in the

EEA.

• Printed Manuals

Model UT130 Temperature Controller (IM 05C01E02-01E)

UT100 Series Communication Functions (IM 05C01E12-10E)

•

General Specifications

Model UT130, UT150 Temperature Controller (GS 05C01E02-01E)

1

■

Checking Package Contents

Before using the product, check that its model & suffix codes are as you ordered.

Model and Suffix Codes

Model

Suffix code

Description

UT130

Temperature controller

Control output for

standard type

(or for heating)

–R

–V

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID)

Control output for

cooling

N

R

V

No cooling output (standard type)

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID)

Option

/AL

/HBA

/RS

/V24

Alarm outputs (2 points)

Heater disconnection alarm (includes optional /AL function)

Communication function

Power Supply 24V DC / 24V AC

Note: When specifying the /RS option, be sure to order the required number of copies of Communication Functions User’s Manual separeately.

Check the package contents against the list below.

• Temperature controller …………………… 1

• Mounting bracket

………………………… 1

• User’s manual (this manual)

…………… 1

1. Notice

The following safety symbol is used both on the product and in this user’s manual.

WARNING

This symbol stands for “Handle with Care.” When displayed on the product, the

operator should refer to the corresponding explanation given in the user’s manual in

order to avoid injury or death of personnel and/or damage to the product. In the manual

the symbol is accompanied by an explanation of the special care that is required to

avoid shock or other dangers that may result in injury or loss of life.

The following symbols are used in this manual only.

CAUTION

Indicates that operating the hardware or software in a particular manner may lead to

damage or result in system failure.

IMPORTANT

Draws attention to information that is essential for understanding the operation and/or

features of the product.

■

Exemption from Responsibility

Make sure that all of the precautions are strictly adhered to. Yokogawa Electric Corporation assumes

no liability for any damage resulting from use of the instrument in contradiction to the precautions.

Also, Yokogawa Electric Corporation assumes no liability to any party for any loss or damage, direct

or indirect, caused by the use or any unpredictable defect of the instrument.

2. What is on the Front Panel ?

a.

g.

e.

d.

c.

f.

b.

Name

Function

a. Data display (red)

• In the operating display, either PV (measured value) or SP (target

setpoint) is indicated. Which parameter takes precedence over the

other depends on the DSP parameter value.

• In the parameter setting display, either the parameter codes or

parameter value is indicated.

• If an error occurs, the error code is displayed.

b. Alarm 1 (AL1) lamp (red)

Lit when alarm 1 is activated.

c. Alarm 2 (AL2) lamp (red)

Lit when alarm 2 is activated.

d. SP display lamp (orange)

• Lit when the SP is displayed or being changed.

• Flashes slowly (approx. once every second) when a parameter code

is displayed.

• Flashes fast when a parameter value is being changed.

e. Output (OUT) display lamps

(Left: orange; right: green)

Lit while control output is being output.

• The left lamp is lit in orange during control output of standard type.

• In heating/cooling control, the left lamp lights up in orange when the

heating-side output is active; while the right lamp lights up in green

when the cooling-side output is active.

f. Data change keys

(Indicated as simply the

and

keys hereafter.)

• When PV is displayed on the operating display, a press of the

or

key switches to the SP display.

• When a parameter code is displayed, pressing either key once displays

the parameter value (which can then be changed).

• Changes SP and the parameter values.

• Pressing the

key decreases the data value and pressing the

key increases it. Holding down the key will gradually increase the

speed of the change.

g. SET/ENT key (data registering key)

(Indicated as simply the

key

hereafter.)

• On the operating display, it switches between the PV and SP displays.

• Registers the data value changed using the data change keys.

• Switches between operating displays or parameter setting displays

sequentially.

• Pressing the key for 3 seconds or longer in the operating display

retrieves the operating parameter setting display.

• Pressing the key for 3 seconds or longer in either an operating or setup

parameter setting display transfers back to the operating display.

Please read through this user's manual to ensure correct usage of the controller and keep it handy for quick reference.

Contents

1. Notice ..........................................................................

1

2. What is on the Front Panel? ........................................

1

3. Installing the Controller ...............................................

1

4. Panel Cutout Dimensions and External Dimensions ...

1

5. Wiring ..........................................................................

2

6. Hardware Specifications .............................................

2

7. Key Operations .......................................................... 3

8. Troubleshooting .......................................................... 3

Revision Record

IM 05C01E02-01E 1st Edition: Oct. ’00

2nd Edition: Feb. ’01

3rd Edition: Jun. ’04

4th Edition

:

Mar.

’16

Model UT130

Temperature Controller

IM 05C01E02-01E

1st Edition Oct. 2000 (YK)

4th Edition Mar. 2016 (YK)

3. Installing the Controller

WARNING

To prevent electric shock, the source of power to the controller must be turned off when

mounting the controller on to a panel.

CAUTION

To install the controller, select a location where:

1. No-one may accidentally touch the terminals;

2. Mechanical vibrations are minimal;

3. Corrosive gas is minimal;

4. The temperature can be maintained at about 23°C

with minimal fluctuation;

5. There is no direct heat radiation;

6. There are no resulting magnetic disturbances;

7. The terminal board (reference junction

compensation element, etc.) is protected from wind;

8. There is no splashing of water; and

9. There are no flammable materials.

● Mount the controller at an angle

within 30° from horizontal with

the screen facing upward. Do not

mount it facing downward.

30° (MAX)

Never place the controller directly on flammable items.

If the controller has to be installed close to flammable items or

equipment, be sure to enclose the controller in shielding panels

positioned at least 150mm away from each side. These panels

should be made of either 1.43mm thick metal-plated steel plates

or 1.6mm thick uncoated steel plates.

150mm

150mm

150mm

150mm

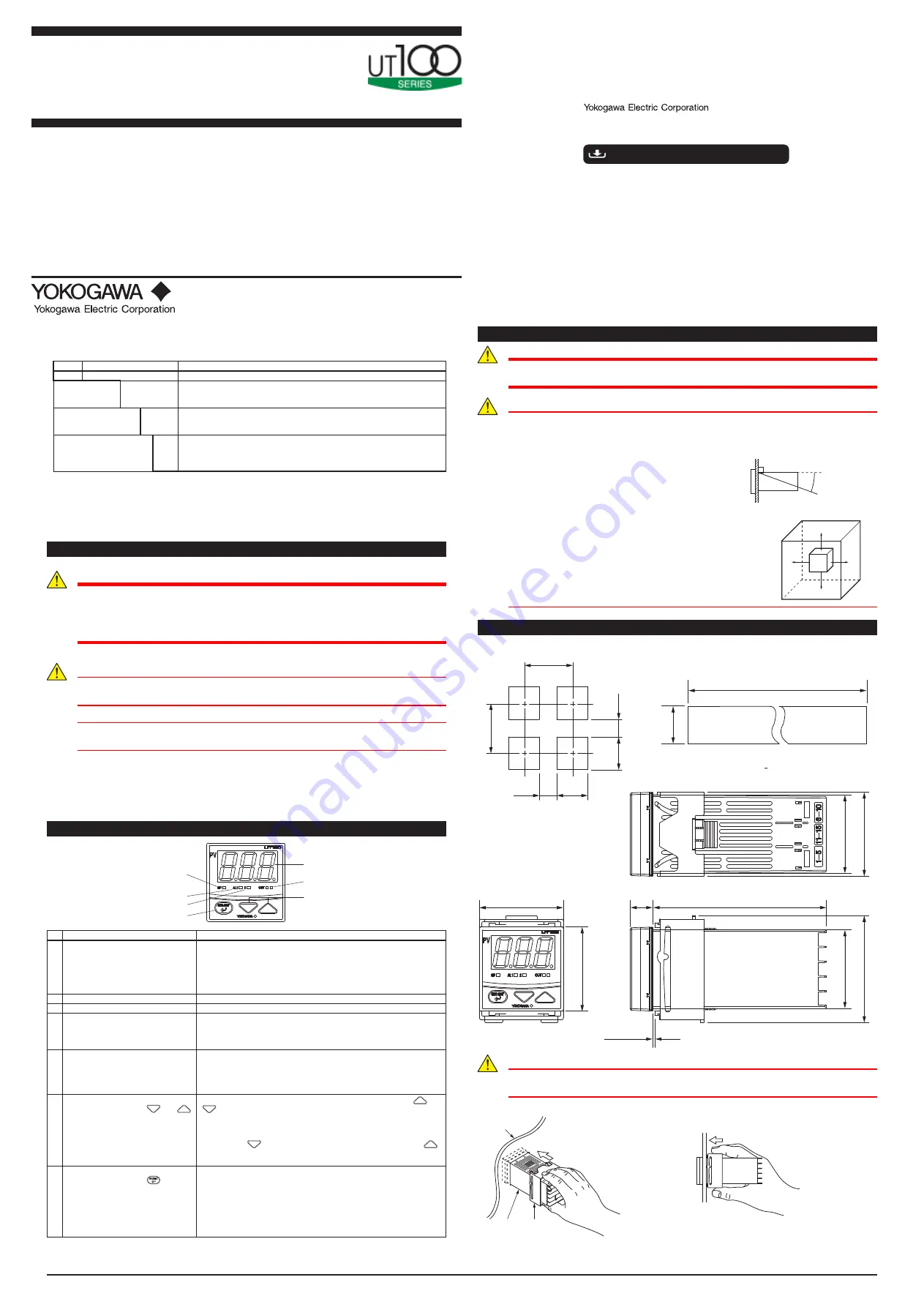

4.

Panel Cutout Dimensions and External Dimensions

1. General Mounting

2. Side-by-side Close Mounting

(Splash-proof construction is unavailable)

Unit: mm

max. 61

Panel thickness

max. 47.8

max. 44.8

max. 44.8

100

12

48

48

1 to 10

min. 70

min. 70

45

+0.6

0

45

+0.6

0

25

25

[(N –1) × 48

+

45]

+0.6

0

+0.6

0

45

N is the number of controllers.

If N>5, then measure the actual length.

CUATION

Splash-proof construction is not available when the side-by-side close mounting

method shown in the above figures, is chosen for any of the controllers.

■

Mounting the Controller

1. Affix the bracket over the back

end of the controller.

2. Push the bracket to the panel,

and then secure the bracket

into position.

Panel

Bracket

UT130

[How to remove the bracket]

To move the bracket, push down the center of the upper and lower parts of the controller softly.

The bracket is released from the latch.