IM 05P08D31-11EN page 3/12

5. How to Connect Wires

WARNING

• Wiring work must be carried out by a person with basic electrical

knowledge and practical experience.

• Be sure to turn OFF the power supply to the controller before

wiring to avoid an electric shock. Use a tester or similar device to

ensure that no power is being supplied to a cable to be connected.

• For the wiring cable, the temperature rating is 75 °C or more.

• As a safety measure, always install a circuit breaker (an IEC

60947-compatible product, 5 A, 100 V or 220 V AC) in an easily

accessible location near the instrument. Moreover, provide

indication that the switch is a device for turning off the power to

the instrument.

• Install the power cable keeping a distance of more than 1 cm

from other signal wires.

• The power cable is required to meet the IEC standards concerned or

the requirements of the area in which the instrument is being installed.

• Wiring should be installed to conform to NEC (National Electrical

Code: ANSI/NFPA-70) or the wiring construction standards in

countries or regions where wiring will be installed.

• Since the insulation provided to each relay output terminal is

Functional insulation, provide Reinforced insulation to the

external of the device as necessary. (Refer to the drawing below.)

This product

Functional

insulation

A safety

voltage circuit

A safety

voltage circuit

This product

Reinforced insulation

Reinforced insulation

Functional

insulation

A hazardous

voltage circuit

A hazardous

voltage circuit

A safety

voltage circuit

A safety

voltage circuit

This product

Reinforced insulation

Reinforced insulation

Functional

insulation

A hazardous

voltage circuit

A hazardous

voltage circuit

A hazardous

voltage circuit

A hazardous

voltage circuit

CAUTION

• When connecting two or more crimp-on terminal lugs to the

single terminal block, bend the crimp-on terminal lugs before

tightening the screw.

• Note that the wiring of two or more crimp-on terminal lugs to the

single high-voltage terminal of the power supply and relay, etc.

does not comply with the safety standard.

CAUTION

• Provide electricity from a single-phase power supply. If the

power is noisy, install an isolation transformer on the primary

side, and use a line filter on the secondary side. When measures

against noise are taken, do not install the primary and secondary

power cables close to each other.

• If there is a risk of external lightning surges, use a lightning

arrester etc.

• For TC input, use shielded compensating lead wires for wiring.

For RTD input, use shielded wires that have low conductor

resistance and cause no significant differences in resistance

between the three wires.

• Since the control output relay has a life span (resistance load of

100,000 times), use the auxiliary relay to perform ON/OFF control.

• The use of inductance (L) loads such as auxiliary relays, motors

and solenoid valves causes malfunction or relay failure; always

insert a CR filter for use with alternating current or a diode for

use with direct current, as a spark-removal surge suppression

circuit, into the line in parallel with the load.

• After completing the wiring, the terminal cover is recommended

to use for the instrument.

● Recommended Crimp-on Terminal Lugs

(A)

(F)

(ød

)

5.5 3.3

Recommended tightening torque: 0.6 N·m

Applicable wire size: Power supply wiring 1.25 mm

2

or more

Applicable terminal lug Applicable wire size mm

2

(AWG#)

(φ d)

(A)

(F)

M3

0.25 to 1.65 (22 to 16)

3.3

5.5

4.2

● Cable Specifications and Recommended Cables

Purpose

Name and Manufacturer

Power supply, relay contact outputs

600 V Grade heat-resistant PVC insulated wires, JIS C

3317(HIV), 0.9 to 2.0 mm

2

Thermocouple

Shielded compensating lead wires, JIS C 1610

For thermocouple input (PV input and remote input with direct

input), shielded compensating lead wire of cross-sectional area

less than or equal to 0.75 mm

2

is recommended. If the cross-

sectional area is wide, the reference junction compensation

error may be large.

RTD

Shielded wires (three/four conductors), UL2482 (Hitachi Cable)

Other signals (other than contact input/output)

Shielded wires

Other signals (contact input/output)

Unshielded wires

RS-485 communication

Shielded wires

Ethernet communication

100 BASE-TX (CAT-5)/10 BASE-T

PROFIBUS-DP communication

Dedicated cable for PROFIBUS-DP (Shielded two-wires)

DeviceNet communication

Dedicated cable for DeviceNet (Shielded five-wires)

CC-Link communication

Dedicated cable for CC-Link (Shielded three-wires)

PROFIBUS-DP/CC-Link Connector (wiring side) (Part number: A1987JT)

DeviceNet Connector (wiring side) (Part number: L4502BW)

Recommended tightening torque: 0.5 to 0.6 N·m

DC Relay Wiring

R

External DC power supply

Relay

UT32A-D

UT’s contact

Diode

(Mount it directly

to the relay coil

terminal (socket).)

Relay

(Use one with a relay coil rating

less than the UT’s contact rating.)

AC Relay Wiring

UT32A-D

R

UT’s contact

CR filter

(Mount it directly

to the relay coil

terminal (socket).)

External AC power supply

Relay

(Use one with a relay coil

rating less than the UT’s

contact rating.)

Transistor Output Wiring

power

+ –

UT

DO

Load

COM

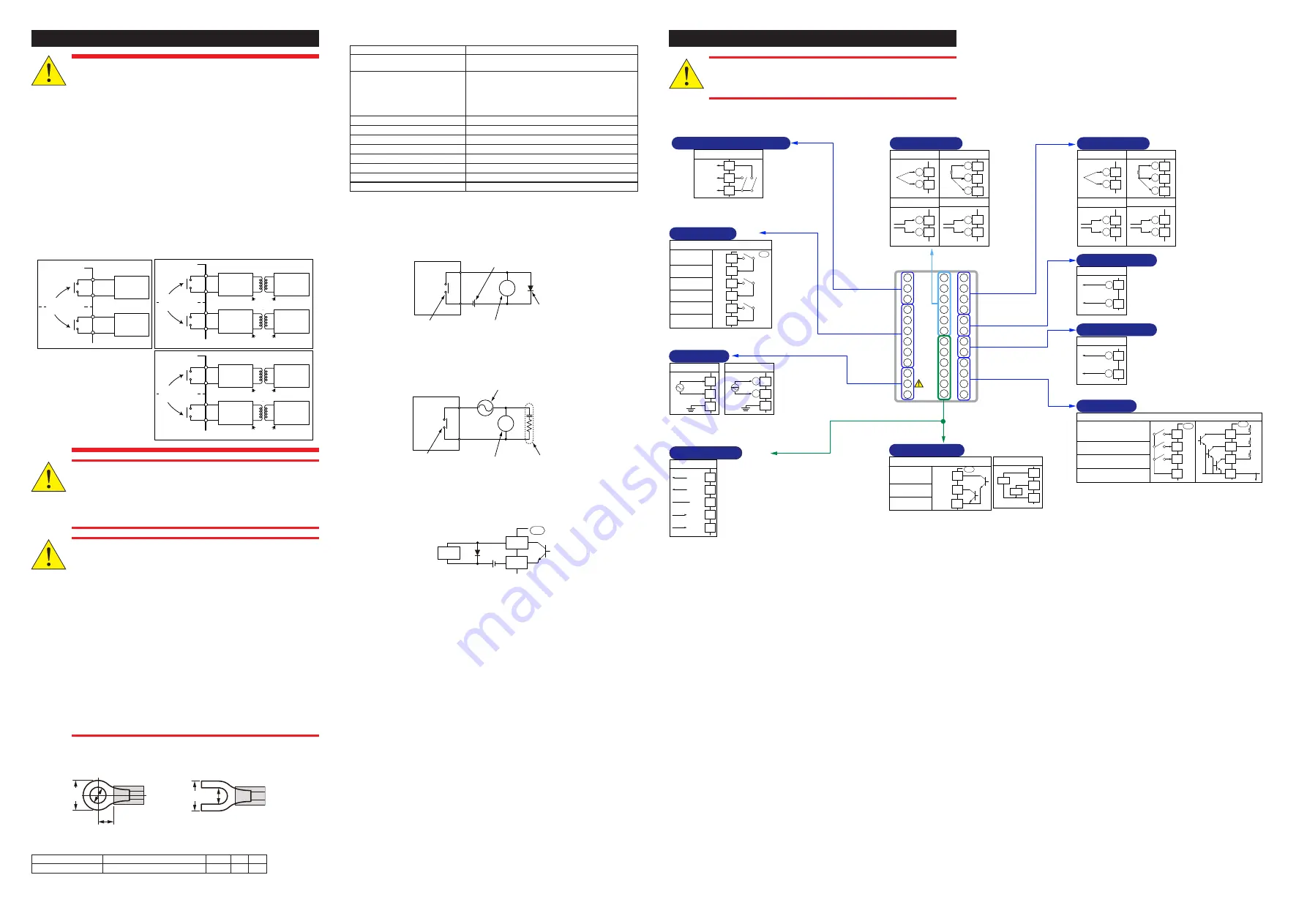

6. Terminal Wiring Diagrams

CAUTION

• Do not use an unassigned terminal as the relay terminal.

Do not use a 100-240 V AC power supply for the 24 V AC/DC

model; otherwise, the instrument will malfunction.

■ UT32A-D

TC input

RTD input

Voltage (mV, V) input

A

+

-

+

-

Current (mA) input

+

-

B

b

111

301

302

303

304

305

306

307

308

309

310

311

312

201

202

203

204

205

206

207

208

209

210

101

102

103

104

105

106

107

108

109

110

211

212

101

-112

301

-312

201

-212

302

303

301

302

303

302

303

303

304

PV2

Contact output

External contact output (relay)

AL3

AL2

AL1

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

Alarm-3 output

(PV high limit)

Alarm-2 output

(PV low limit)

Alarm-1 output

(PV high limit)

Common

Common

Common

UT

104

105

106

107

108

109

ALM

Factory default:

PV input type is

0-10V DC.

Loop-1 PV input

Loop-2 PV input

TC input

RTD input

Voltage (mV, V) input

A

+

-

+

-

Current (mA) input

+

-

B

b

202

203

201

202

203

202

203

203

204

PV1

Factory default:

PV input type is

undefined.

(Option code /HA)

Heater break alarm

Heater current detection input

CT1

CT2

COM

310

311

312

HBA

External contact output (transistor)

Transistor contact rating: 24 V DC, 50 mA

Heater break alarm-1

output

Heater break alarm-2

output

Common

HAL1

HAL2

COM

UT

307

308

309

Loop-1 and Loop-2 control output

Relay contact output

NO

NO

COM

Contact rating: 240 V AC, 3 A

30 V DC, 3 A (resistance load)

101

102

103

Factory default: Control output is relay.

OUT

OUT2

112

Power supply

24 V AC/DC power supply

-

+

100-240 V AC power supply

Allowable range:

100-240 V AC (+10%/-15%)

(free voltage)

50/60 Hz shared

N

L

(24 V AC/DC power supply:

Option code /DC)

110

111

110

111

112

112

N

L

Current/voltage pulse output

0-20 mA DC,

4-20 mA DC,

Voltage pulse (12 V)

-

Loop-2 control output

+

205

206

OUT2

Control output is relay at factory default.

Current output range can be changed.

Loop-1 control output

Current/voltage pulse output

0-20 mA DC,

4-20 mA DC,

Voltage pulse (12 V)

+

-

207

208

OUT

Control output is relay at factory default.

Current output range can be changed.

RS-485

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

RS-485 communication

(Suffix code:

Type 2=1)

307

308

309

310

311

RS485

DI

Contact input

Contact rating: 12 V DC, 10 mA or more

External contact input

DI3

DI2

DI1

COM

Common

DI3

DI2

DI1

COM

+5V

+5V

+5V

No-voltage

contact

Transistor contact

UP

UP

209

210

211

212

209

210

211

212

Functions can be changed.

Loop-1 AUTO when DI1=ON

Loop-1 MAN when DI1=OFF

Loop-2 AUTO when DI3=ON

Loop-2 MAN when DI3=OFF

Loop-1 and Loop-2 STOP when DI2=ON

Loop-1 and Loop-2 RUN when DI2=OFF