5-6

<Wiring>

IM 01W06F02-01EN

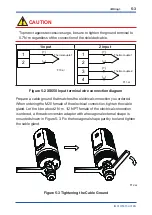

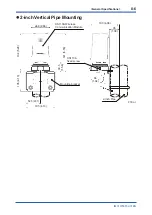

5.4 Grounding

Ensure continuity (Resistance less than 0.2 MΩ) between the grounding

terminal and grounding pole in Figure 5-6 or Figure 5-7. Grounding resistance

100 Ω or less is recommended. If continuity between the ground terminal and

the ground electrode cannot be ensured, use the cable described in Section

5.2. Do not share the ground wiring of the XS550 with other devices .

Ground terminal

F15.ai

Figure 5-6 Ground Terminal

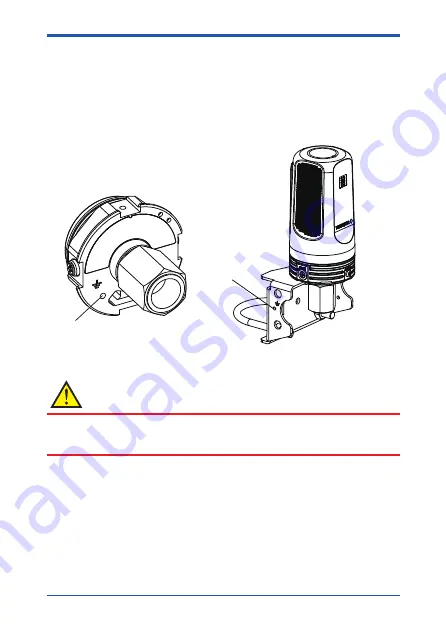

F16.ai

Ground terminal

Figure 5-7 Ground Terminal on bracket side

CAUTION

Grounding is required for safe operation. The input cable shield should be

connected to grounding terminal inside of the housing.