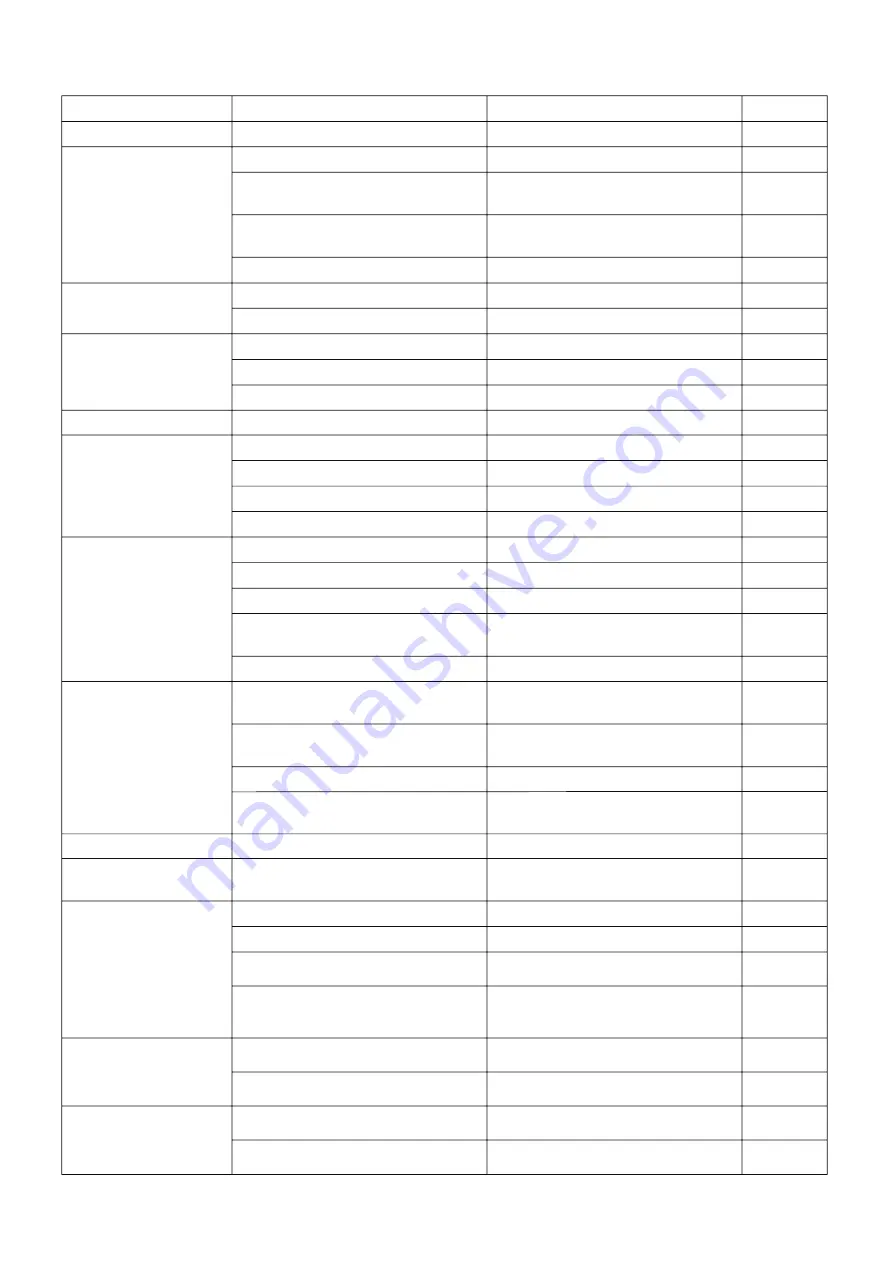

5. PERFORMANCE CHECKLIST

GENERAL PROBLEMS

Machine does not sew.

Power switch is turned off.

Turn on the switch.

Buttonhole lever is not lowered when sewing

buttonhole.

Lower buttonhole lever.

Bobbin winder is engaged.

Disengage bobbin winder.

See page 6

See page 30

See page 4

See page 30

Machine jams/knocks.

Thread is caught in hook.

Clean hook.

See page 32

Needle is damaged.

Replace needle.

See page 11

Fabric dose not move.

Presser foot is not lowered.

Lower presser foot.

Stitch length is too short.

Lengthen stitch length.

See page 16

Darning plate is placed on needle place.

Remove darning plate.

STITCHING PROBLEMS

Machine skips stitches.

Needle is not all the way up into needle clamp.

See page 11

Needle is bent or blunt.

Replace needle.

See page 11

Machine is not threaded correctly.

See page 8

Thread is caught in hook.

Clean hook.

See page 32

Stitch are irregular.

Needle size is not correct for thread and fabric.

See page 11

Machine is not threaded correctly.

See page 8

Top thread tension is too loose.

See page 14

Fabric is being pulled or pushed against machine

feeding action.

Bobbin has not been wound evenly.

Needle breaks.

Fabric is being pulled or pushed against machine

feeding action.

Needle size is not correct for thread and fabric.

See page 11

Needle is not all the way up into needle clamp.

See page 11

See page 33

THREAD PROBLEMS

Thread bunches.

Top and bobbin threads are not drawn back under

presser foot before starting seam.

See page 19

Draw both threads back under presser foot about 6"

(15 cm) and hold until a few stitches are formed.

Needle thread breaks.

Machine is not threaded correctly.

See page 8

Top thread tension is too tight.

See page 14

Needle is bent.

Replace needle.

See page 11

Needle size is not correct for thread and fabric.

See page 11

Bobbin thread breaks.

Bobbin case is not threaded correctly.

See page 7

Lint accumulates in bobbin case or hook.

See page 32

Guide it gently.

Guide it gently.

Rewind bobbin.

Remove lint.

Fabric puckers.

See page14

Top thread tension is too tight.

Adjust top thread tension.

Adjust top thread tension.

Adjust top thread tension.

See page16

Stitch length is too long for sheer or soft fabric.

Shorten stitch length.

Condition

Causes

Solutions

Reference

There is a gap between slider and spring holder on

buttonhole foot.

Press the buttonhole foot lightly to avoid the gap

between slider and spring holder.

Re-fix the needle.

Re-fix the needle.

Re-threading.

Re-threading.

Re-threading.

Re-threading.

Change either needle or thread.

Change to another type of needle.

Not push the twin needle button when use twin

needle.

Push twin needle button.

Change to another type of

t

hread.

Change to another type of needle.

Change to another type of

t

hread.

37

Summary of Contents for KP6210

Page 1: ...KP6210 KP6210A 210x297...

Page 12: ......

Page 15: ...Place the large extension table along the machine body as illustrated...

Page 16: ......

Page 31: ...29...

Page 40: ...621960007 BS01 04 2018...