107273-UUM-C-0306

4

Unitary Products Group

To Turn Off the Appliance:

1.

Set the thermostat to lowest setting.

2.

Turn off all electric power to the appliance if service is to be per-

formed.

3.

Remove burner access panel.

4.

Turn the valve attached to the oil pump to the closed position.

5.

Replace burner access panel.

NOTE: When opening valve attached to the oil pump. turn handle until

valve opens to a snug stop. DO NOT torque down handle as this will

strip threads and valve will need to be replaced.

FURNACE USER MAINTENANCE

Air Filters

Dirty filters greatly restrict the flow of air and may cause damage to the

moving parts of the furnace. If the filters become clogged the heat

exchangers and blower motor could overheat resulting in a potentially

dangerous situation.

The filters should be checked every 3 months. On new construction,

check the filters every week for the first four weeks and every three

weeks after that, especially if the indoor fan is running continuously.

When replacing the filter(s) you must use filters that are the same size

as those recommended in Table 1. Never operate your furnace without

a suitable air filter. NEVER use PLEATED MEDIA or HOGS HAIR air fil-

ters in this furnace.

Every time the filters are changed the following items should be visually

inspected:

•

Check vent pipe for blockage or leakage.

•

Check all components to be sure they are in good condition and

that there are no obvious signs of deterioration.

•

Check for dirt or lint on any surfaces or on components. Do not try

to clean any of the surfaces or components. Cleaning of the fur-

nace and its components must be done by a qualified service pro-

fessional.

Removing Filters

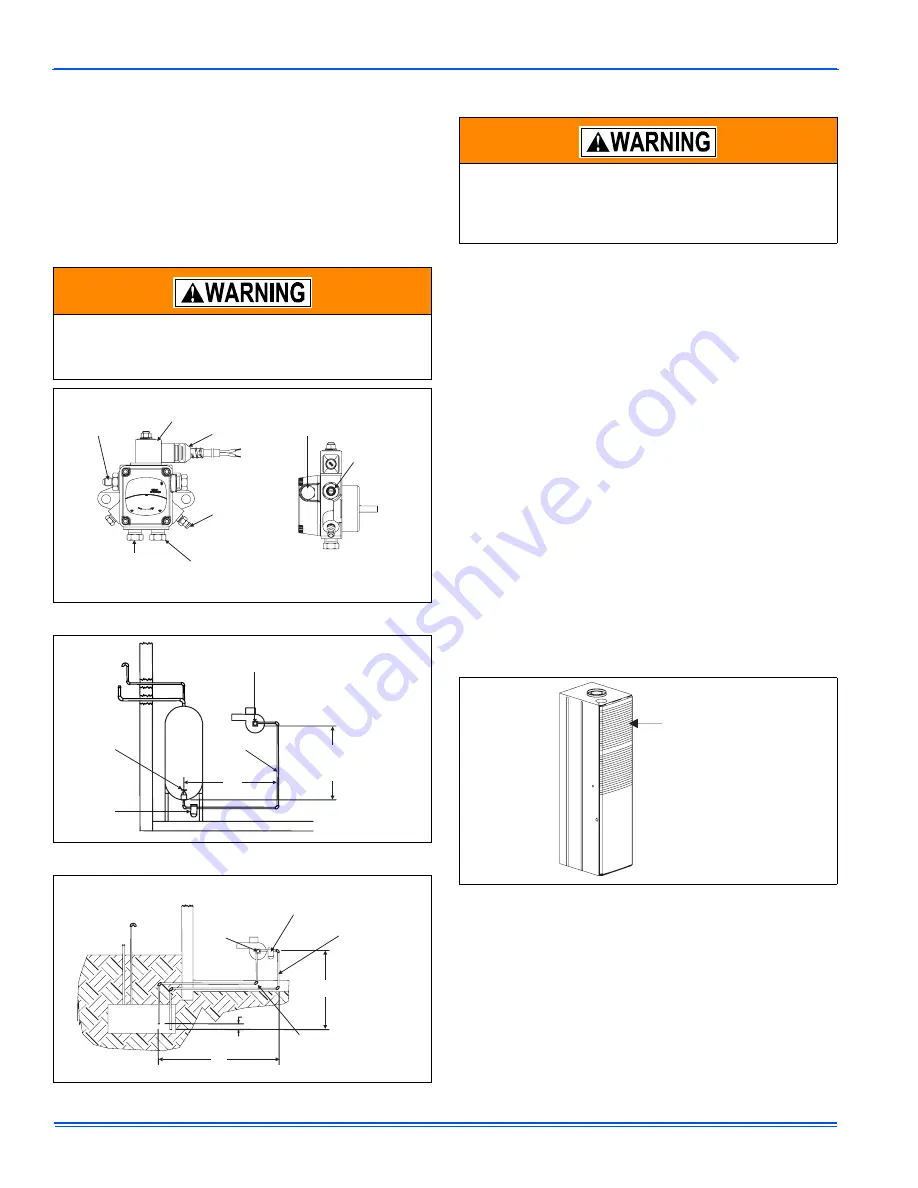

Internally Mounted Air Filters

The air filter is in a rack that is attached to the inside of the louvered

blower door. Refer to Figure 7 for air filter location.

To remove the filter you must do the following:

1.

Before proceeding, be sure the area is well ventilated. Follow

instruction “To turn off the appliance”. Check all metal parts and

surfaces to be sure they have cooled to room temperature before

you begin.

2.

Remove the louvered blower door by pulling on the indentated

handles on both sides of the bottom of the door.

3.

Remove the air filter by sliding them down. The air filter will slide

out of the rack.

4.

Replace throw away filter(s) with the same size new filter(s) and

the same type air filter(s). DO NOT use pleated media, hogs hair,

or cleanable air filters.

Should overheating occur, or the oil burner fail to shut off, turn

the external manual valve on the oil pump or oil line at the oil

tank to the off position and let the furnace cool off before shut-

ting off the electrical power supply. Refer to Figures 4, 5, and 6.

FIGURE 4: Oil Pump

FIGURE 5: One-Pipe System

FIGURE 6: Two-Pipe System

4 GPH 100-150 PSI 3450 RPM

3 GPH 150-200 PSI 3450 RPM

NO. 2 & LIGHTER FUEL

INLET

BY-PASS

Exclusively for Beckett

Made by Suntec

INLET

NO. 2 FUEL

A2EA-6520

Beckett

CLEAN

CUT

USE ONLY WITH

VALVE ON DELAY

Pressure

Adjustment

Screw

Inlet Port

1/4 NPTF

Bleed &

Gauge Port

Return Port

Install 1/16” by Pass Pipe

Plug For Two-Pipe System Only

(Use 5/32” Allen Wrench)

Cordset

By Pass

Solenoid

Valve

Inlet Port

1/4 NPTF

(0.64 cm)

Nozzle Port

3/16 Flare

Fittting

Oil

Tank

Maximum

One Pipe (H)

Lift: 8 Ft

“R”

Inlet

Fuel Unit

Primary

Filter

Shut-Off

Valve

Fill

Pipe

Air

Vent

L = H + R

Oil

Tank

Fill

Pipe

Air

Vent

Outside Tank Fuel Unit

Above Bottom of Tank

Fuel

Unit

Inlet

Primary

Filter

L = H + R

“R”

“H”

Use Protective Plastic

Tubing in Concrete or as

Local Codes Require

3” - 4”

Before proceeding, be sure the area is well ventilated. Turn the

thermostat OFF. If the blower is running, wait until it stops auto-

matically. Turn OFF the oil and electrical power supplies to the

furnace. Check all metal parts and surfaces to be sure they

have cooled to room temperature before you begin.

FIGURE 7: Furnace Air Filters

Air Filters Can Be

Found On The Inside

Of This Access Panel