5

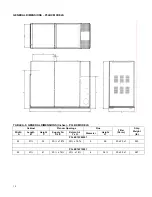

Fig. 2: Common Chimney Problems

Table 2: Common Chimney Problems

Refer to Figure 2

Key Trouble Diagnostic Remedy

A

Top of chimney

lower than sur-

rounding ob-

jects

Observation

Extend chimney

above all sur-

rounding ob-

jects within 30

feet.

B

Chimney Cap

or ventilator.

Observation Remove

C

Coping restricts

opening.

Observation

Make opening

as large as

inside of chim-

ney.

D

Obstruction in

chimney

Can be found

by light and

mirror reflecting

conditions in

chimney.

Use weight to

break and dis-

lodge.

E

Joist protruding

into chimney.

Lowering a light

on an extension

cord.

Must be han-

dled by compe-

tent masonry

contractor.

F

Break in chim-

ney lining.

Smoke test -

build smudge

fire blocking off

other opening,

watching for

smoke to es-

cape.

Must be han-

dled by compe-

tent masonry

contractor.

G

Collection of

soot at narrow

space in flue

opening.

Lower light on

extension cord.

Clean out with

weighted brush

or bag of loose

gravel on end

of line.

H Offset

Lower light on

extension cord.

Change to

straight or to

long offset.

I

Two or more

openings to the

same chimney.

Found by in-

spection from

basement.

The least im-

portant opening

must be closed,

using some

other chimney

flue.

J

Loose-seated

pipe in flue

opening.

Smoke test.

Cementing all

pipe openings

should elimi-

nate leaks.

K

Smoke pipe

extends into

chimney.

Measurement

of pipe from

within or obser-

vation of pipe

by means of a

lowered light.

Length of pipe

must be re-

duced to allow

end of pipe to

be flush with

inside of tile.

L

Failure to ex-

tend the length

of flue partition

to the floor.

By inspection or

smoke test.

Extend partition

to floor level.

M

Loose-fitted

clean-out door.

Smoke test.

Close all leaks

with cement.

DRAFT REGULATOR CONTROL

This device is used in conjunction with conventional chimney

venting. This control (or draft regulator) automatically maintains

a constant negative pressure in the furnace to obtain maximum

efficiency. It ensures that proper pressures are not exceeded. If

the chimney does not develop sufficient draft, the draft control

cannot function properly. The draft regulator, must be installed

within the same room or enclosure as the furnace, and should

Summary of Contents for P3HMX12F08001

Page 16: ...16 APPENDIX A WIRING DIAGRAM ...