5052617-UIM-E-1116

Johnson Controls Unitary Products

7

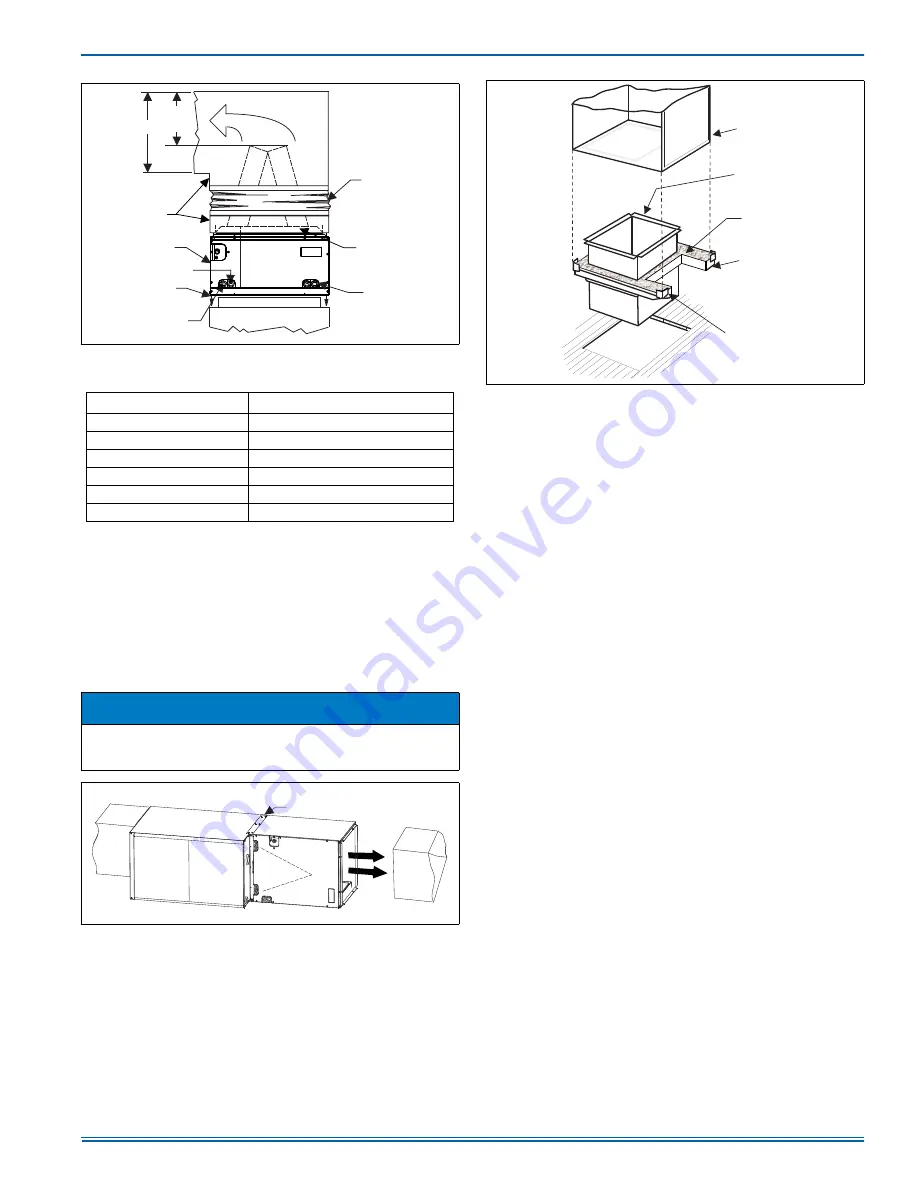

Dimension “C” should be at least 2/3 of dimension “D”. See Figure 6.

CRITICAL COIL PROJECTION

The coil assembly must be located in the duct such that a minimum dis-

tance is maintained between the top of the coil and the top of the duct.

Refer to Table 2.

COIL / FURNACE ASSEMBLY - HD SERIES COILS

Horizontal duct coils are referred to as HD series coils. This coil must

be connected using a supply duct transition. This coil is direction sensi-

tive. Refer to the HD coil installation instructions for more information.

RESIDENTIAL AND MODULAR HOME UPFLOW

RETURN PLENUM CONNECTION

Return air may enter the furnace through the side(s) or bottom depend-

ing on the type of application. Return air may not be connected into the

rear panel of the unit.

SIDE RETURN APPLICATION

Side return applications pull return air through an opening cut in the

side of the furnace casing. This furnace is supplied with a bottom block-

off panel that should be left in place if a side return is to be used. If the

furnace is to be installed on a flat, solid surface, this bottom panel will

provide an adequate seal to prevent air leakage through the unused

bottom opening. However, if the furnace is to be installed on a surface

that is uneven, or if it is to be installed on blocks or otherwise raised off

the floor,

it will be necessary to seal the edges of the bottom panel

to the casing using tape or other appropriate gasket material to

prevent air leakage.

BOTTOM RETURN AND ATTIC INSTALLATIONS

Bottom return applications normally pull return air through a base plat-

form or return air plenum. Be sure the return platform structure or return

air plenum is suitable to support the weight of the furnace.

The internal bottom panel must be removed for this application.

Attic installations must meet all minimum clearances to combustibles

and have floor support with required service accessibility.

FIGURE 6:

PC Series Upflow Coil Installation

Table 2:

Coil Projection Dimensions - PC Series Coils

COIL SIZE

DIMENSION “C” INCH

PC18

3-1/2

PC24

4-1/2

PC30, PC32, PC35

4-1/2

PC42, PC43, PC36, PC37

5-1/2

PC48

6-1/2

PC60

9

NOTICE

Each coil is shipped with external tie plates that should be used to

secure the coil to the furnace. They should be installed on the back

and both sides of the coil using sheet metal screws. See Figure 7.

FIGURE 7:

Horizontal Left or Right Application (Right Shown)

F

lexible

Duct

C

onnector

Do not drill

or

S

crew

this flange

F

ield

F

abricated

Ductwork

Upflow

C

oil

Upflow

F

urnace

S

econdary Drain

Primary Drain

D

C

(

M

in)

A

lternate

Drain Location

A

0432-001

G

as

F

urnace

Use tie plates

supplied with coil

A

ir flow

A

0446-001

FIGURE 8:

Combustible Floor Base Accessory

FURNACE

WARM AIR PLENUM

WITH 1” FLANGES

FIBERGLASS

INSULATION

FIBERGLASS TAPE

UNDER FLANGE

COMBUSTIBLE FLOOR

BASE ACCESSORY