MAXA-MI$ER

Ô

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR011A12H & B12H (STATIONARY)

INSTALLATION

INSTRUCTIONS

5257541-UAI-A-0616 / R11A-29YSDW

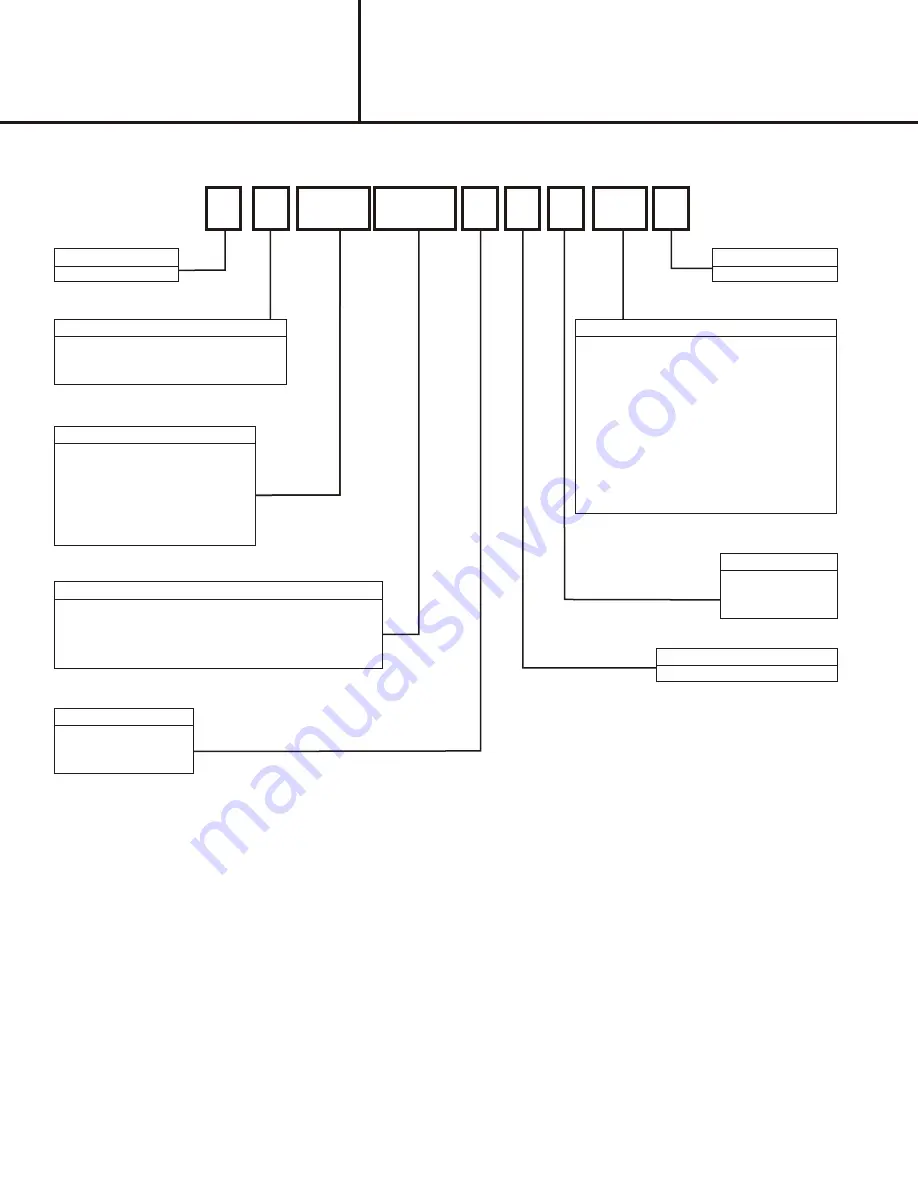

York UERV Model Nomenclature

V R 028 A12 H 4 A L2 1

Wheel Type

R = Rooftop Stationary

O = Stand Alone Over and Under, Stationary

S = Stand Alone Side by Side

P = Rooftop Pivoting (036-060 & 078-150 only)

Prod uct Cat e gory

V = Ventilator

CFM*

006 = 300 to 550

011 = 600 to 1000

020 = 1100 to 1700

028 = 2200 to 2800** 1500 to 2200**

036 = 2800 to 3600

046 = 3400 to 4600

062 = 5500 to 6200** 4800 to 5600**

074 = 6000 to 8000

122 = 8000 to 13000

York Roof top Cab i net

A06 = Small Sunline ZF/ZR/XP036-072

A12 = 50" Predator ZF/ZH/ZR/XP*102-150, ZJ076-150

B12 = 42" Predator ZF/ZR/XP078-090, ZH0037-090, ZJ/ZR076-150

A15 = Large Sunline ZF180

A25 = Large Sunline ZF210-300, ZJ180-300, XP180-240

A40 = Millennium 25, 30 and 40 Ton Package

Blower Speed

H = High Speed**

M = Medium Speed**

V = Variable Speed

L = Constant Volume

Prod uct Gen er a tion

1 = First Generation

Ad di tional Op tions

AA = No Options Installed

L1 = Low Ambient Kit (LAK)*

L2 = LAK & MOA*

L3 = LAK & MOA & SSJ (not used on P models)*

L4 = LAK & MOA & SSJ & PS (not used on P models)

L5 = LAK & SSJ (not used on P models)*

L6 = LAK & SSJ & PS (not used on P models)

L7 = LAK & PS

L8 = LAK, MOA and PS

M1 = Motorized Outside Air (MOA)*

M2 = MOA & SSJ (not used on P models)*

M3 = MOA & SSJ & PS (PS) (not used on P models)

M4 = MOA & PS

S1 = Stop-Start-Job (SSJ) (not used on P models)*

S2 = SSJ & PS (not used on P models)

P1 = Pressure Sensor (PS)

Volt age

2= 208/230v-3ph

4= 460v-3ph

5= 575v-3ph

9= 208/320v-1ph

Duct Type

A = No Selection on Rooftop Units

PAGE 6

*

CFM is ERV wheel rating. This may vary depending on unit cabinet pressure drop.

**

These CFM ranges are dependant upon blower motor selection.

Low Ambient Kit

(

LAK

) - Defrosts wheel when low ambient temp near the exhaust blower shows possible frost up.

Start-Stop-Jog

(

SSJ

) - provides a "free cooling" mode by stopping enthalpy wheel when temps are appropriate for free

cooling.

Motorized Outside Air

(

MOA

) damper - closes a damper on the outside air intake when the ERV is not in use.

Pressure Sensor

(

PS

) - Analog differential pressure gauge (Magnahelic) shows pressure drop across the wheel in

Inches of Water.