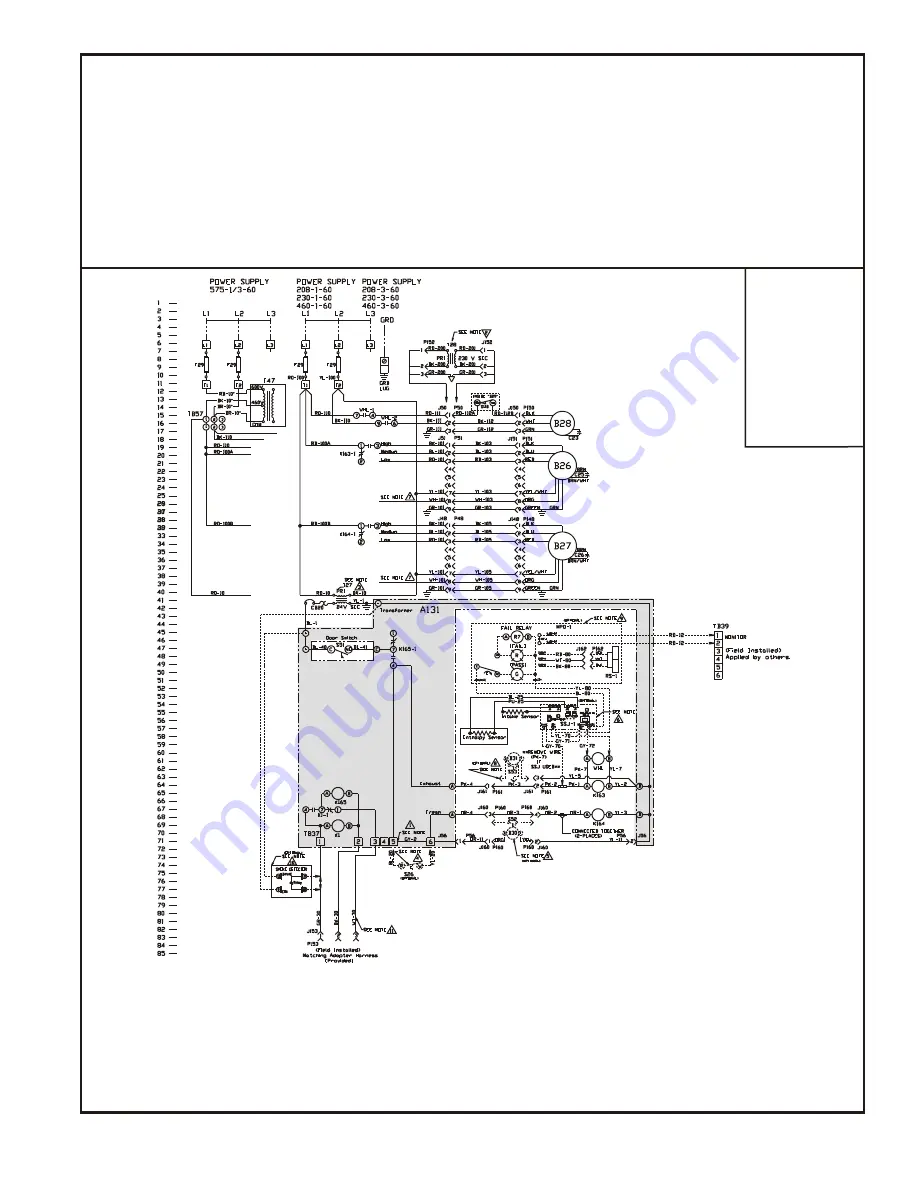

PAGE 9

R11A-29YSDW

COMPONENT CODE

A131

Fixed Relay Board

B26

Motor, Exhaust Air

B27

Motor, Fresh Air

B28

Motor, Desiccant Wheel

B30

Motor, Damper (Optional)

B31

Motor, Damper Exhaust (Optional)

C23

Capacitor, Wheel Motor

C25

Capacitor, Motor Exhaust Air

C26

Capacitor, Motor Fresh Air

F29

Fuse

J48

Jack, Control Box (Fresh Air)

J50

Jack, Control Box (Wheel)

J51

Jack, Control Box (Exhaust Air)

J56

Jack, Control Box (Damper)

J148

Jack, Fresh Air Motor Harness

J150

Jack, Wheel Motor Harness

P153

Plug, Field Harness

P160

Plug, Damper Motor

P161

Plug, Damper Exhaust Motor Harness

RS-1

Rotation Sensor (Optional)

S26

Switch, Low Ambient (Optional)

S51

Switch, Door

S52

Switch, Damper Intake

S53

Switch, Damper Exhaust

SSJ

Climate Smart Board (Optional)

T27

Transformer, Control

T28

Transformer, Step-down (Optional)

T47

Transformer, Step-down (Optional)

TB37

Terminal Block (Low Voltage)

TB38

Terminal Block (Monitoring)

TB57

Terminal Block (High Voltage)

WHL

Relay, Wheel Motor

J151

Jack, Exhaust Air Motor Harness

J152

Jack, Transformer (High Voltage)

J153

Jack, Field Harness

J160

Jack, Damper Motor Harness

J161

Jack, Damper Exhaust Motor Harness

K163

Relay, Exhaust Air Motor

K164

Relay, Fresh Air Motor

MPD-1

Missing Pulse Detector Board (Optional)

P48

Plug, Fresh Air Motor Harness

P50

Plug, Wheel Motor Harness

P51

Plug, Exhaust Air Motor Harness

P56

Plug, Damper Motor Harness

P148

Plug, Fresh Air Motor

P150

Plug, Wheel Motor

P151

Plug, Exhaust Air Motor

P152

Plug, Transformer (High Voltage)

WIRE COLOR

CODE

BK

Black

BL

Blue

GR

Green

GY

Gray

OR

Orange

PK

Pink

RD

Red

WT

White

YL

Yellow

Notes:

1. Re move jumper to in stall field op tional low am bi ent switch.

2. Step-down trans former as sem bly for 460/575 volt units (only) con nect be tween J50 and P50.

3. Se lec tive volt age ter mi nal for proper unit volt age.

4. Op tional low am bi ent switch.

5. Op tional mo tor ized in take damper.

6. Op tional stop, start and jog con trol.

7. Unit may be wired for HI, MED, or LO speeds. Di a gram shows the HI speed setup, to re wire for MED or LO speed,

dis con nect BK-101 from re lays and con nect BL-101 for MED, or RD-101 for LO. Also con nect WH-101 to BK-101.

8. Op tional mo tor ized ex haust damper.

9. Op tional wheel ro ta tion sen sor.

10. Op tional smoke de tec tor

11. Match ing adapter har ness (pro vided) to con nect with roof top unit.