PAGE 13

MAXA-MI$ER

Ô

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR028A15M/H & VR028A25H (STATIONARY)

INSTALLATION

INSTRUCTIONS

5257527-UAI-A-0616 / R28A-18YSDW

In order for the ERV to operate with maximum

effectiveness the Smart Equipment Control (SEC) must

have the latest 3.1 (or greater) firmware installed. In order

to determine the version of firmware present within the

control follow the menu steps below.

Status> Scroll down to "Update"> Enter> View Version

If a firmware update is required be sure to perform a

backup of the units factory settings if updating the

firmware. The procedure below outlines the backup and

restore functions of the SE units control board. Once the

procedures outlined in the document, the following set

points will have been changed to the status shown below.

I - Set Points

Set Points

Sta tus

BACOid

Economizer En able

ON

29747

Power Ex haust En able

ON

29787

Non-Mod u lat ing Power Ex haust

ON

29503

These settings can be accessed within the RTU- SE UCB

menu. Please refer to the RTU's SE "

Quick Start

" guide

for menu navigation using the onboard LCD display,

joystick and enter/cancel buttons.

Please see the

following pages for instructions on how to navigate

the Smart Control (SE) menus and setting up the

control to operate with an ERV.

II - SE Procedures to Backup / Restore

1.

Once the packaged unit is powered up the 120 second

startup delay begins. Once the delay expires there

may or may not be a "

Start Up

" delay displayed. To

cancel the second time delay press the "

Cancel

"

button for six seconds.

See Figure 1.

Startup

Figure 1

Update

Figure 2

Backup

Figure 3

2.

Once the control is out of time delay mode, press the

Joystick down through the following menus:

Status>

Alarms> Summary> Commission> Controller>

Update, Push ENTER

(

See Figure 2

)

3.

Once the screen and cursor are on "

Update

".

Press

Enter

and scroll through the menus until the

screen and cursor displays "

Backup

". If an USB flash

drive is present or is inserted into the on board USB

port, pressing enter when "

Backup

" is displayed the

backup will begin sending factory defaults and other

settings to the USB flash drive.

See Figure 3.

4.

Once the backup is performed (Screen shows BCFG

100%) the 3.1 or greater version of the controls

firmware can be loaded. Please see the details on the

following pages on how to perform the firmware

updates.

III– SE Procedures to Update

Updating the program in the SE control by USB if

required.

WARNING!

In order for the ERV to properly operate with

the SE control version 3.1.0.0.0128 or greater must be

installed. Load the appropriate files to a clean USB Flash

Drive as indicated in the prior five steps.

(Files located on UPGNET>UST and Technical

Services Center>Tech Services Software Updates)

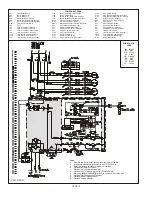

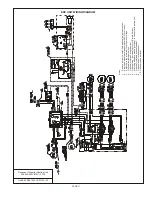

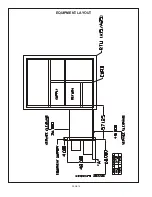

Summary of Contents for VR028A15H

Page 9: ...PAGE 9 ...

Page 12: ...PAGE 12 EQUIPMENT LAYOUT ...