PAGE 15

MAXA-MI$ER

Ô

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR028A15M/H & VR028A25H (STATIONARY)

INSTALLATION

INSTRUCTIONS

5257527-UAI-A-0616 / R28A-18YSDW

8.

Press

ENTER

again.

Screen will read

FWU WAIT

then the program will load.

This could take up to 10 minutes or more. The screen

contents will change several times during the update so

be

patient…

Wait until base screen reappears. Re-programming is

complete for the firmware. Now that the new firmware is

loaded it is time to restore the backup data from earlier

s t e p . S c r o l l t o :

S t a t u s > A l a r m s > S u mm a r y>

Commission> Controller> Update> View Version>

Load Firmware> Backup> Restore

press

Enter

and the

screen will request the user indicate which restore file to

use. The backup files should be named after the units

serial number. Scroll to the appropriate units serial number

on the screen and press

Enter

. The restore should only

take 15-20 seconds. Once the restore is complete the SE

unit control will reboot.

Note: If updating a version "H"

board it may require two firmware updates to take

place. Please verify the active version of firmware after

updating.

If the unit does not reboot, restart cycle power to the unit

and wait again for re-boot start-up.

If loading more than one file, example upgrading CDR unit

from version 1, you should cycle power after loading the

first file and again after the last file is complete.

It is a good practice to conduct a "RE-LEARN" from within

the menu after the file(s) have been upgraded if the

function of the unit does not appear to be normal.

Status>

Alarms> Summary> Commission> Controller>

IV - SE Procedures to Setup Operation for ERV

In order for the SE unit controller, SE economizer control

a n d E R V t o o p e r a te p r o p e r l y t h e f o ll o w i n g

changes/settings will need to be performed within the SE

unit control.

1.

Scroll through menus by pressing down on joystick:

Status> Alarms> Summary> Commission> Econ>

Economizer Enable- Make sure this is set to "Yes"

ERV-En

Figure 11

Econ-En

Figure 10

2.

Scroll through menus by pressing down on joystick:

Status> Alarms> Summary> Commission>

PowerEx> ERV Enable- Make sure this is set to

"Yes"

3.

The economizer minimum setting must be set at 50%

or greater.

Status> Alarms> Summary> Commission>

PowerEx> ERV Enable- Make sure this is set to

"Yes"

4.

Once the ERV is set to "

Enable

" the ERV will operate

any time the unit is in the occupied mode. The ERV, if

equipped with pivoting wheel, will rotate the wheel out

of the air stream anytime the packaged units

economizer enters the free cooling mode. In order to

test for proper operation the unit must see a call for

cooling (24 vac on the Y1 terminal) and an outdoor

temperature of 55

o

F or less. If the outdoor ambient

temperature is above 55

o

F the unit may not enter free

cooling. If the ambient temperature is above 55

o

F the

packaged unit can be forced into free cooling mode by

doing the following:

5.

Scroll through menus by pressing down on joystick:

Status> Alarms> Summary> Commission>

Controller> Update> Details,

under details press

Enter

then scroll to the Service

menu heading, press

Enter

then scroll to

Inputs>

NetworkInputs

, scroll to

NetOAT

and change it to a

setting well below the 55

o

F default by toggling the

joystick left or right to increase/decrease the value,

then pressing

Enter

to store the new value. If the

setting is now 30

o

F for example the unit should go into

free cooling mode within a few minutes of the

change. Note: Once the NetOAT is forced to a

temperature below 55

o

F

it will remain at the forced

value for 15 minutes and revert back to default

settings.

For additional details on navigating, changing and

operating the SE unit control board please refer to the

SE (Smart Equipment) Controls Quick Start Guide

(Document # 1136326-USG-C-0216) that is shipped

with the packaged unit.

Summary of Contents for VR028A15H

Page 9: ...PAGE 9 ...

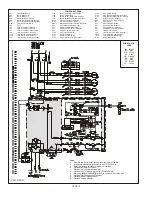

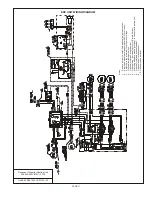

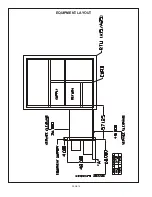

Page 12: ...PAGE 12 EQUIPMENT LAYOUT ...