6.7

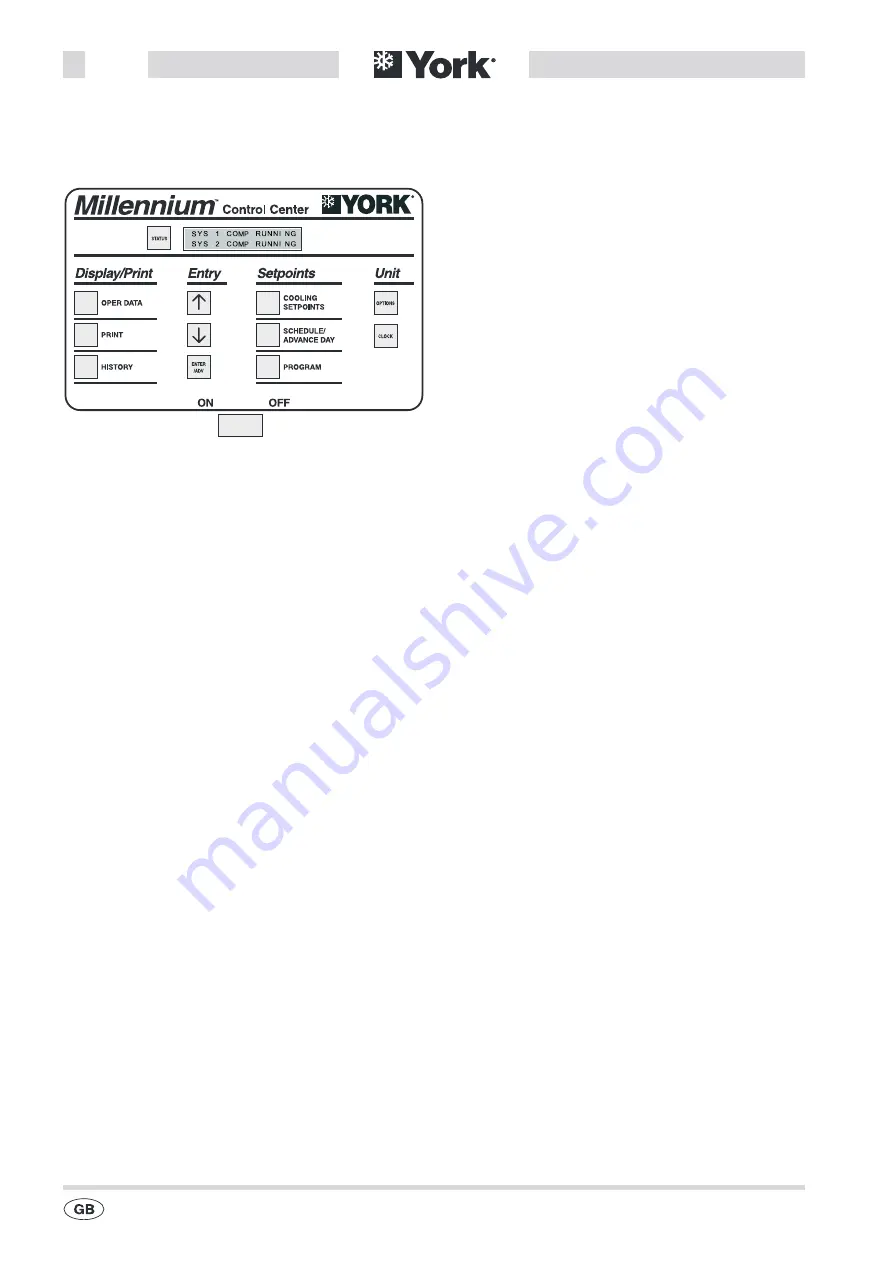

ISN Control Panel (Standard YCAA models 170 -

210, optional YCAA models 60 - 150)

The panel shall contain:

l

A 40 character Liquid Crystal Display (LCD) with Light

l

Emitting Diode (LED) back lighting for outdoor

viewing.

l

A Colour coded 12-button keypad.

l

Customer terminal block for control inputs and liquid

flow switch.

The microprocessor control will include:

Status Key for display of:

l

Status of the unit and each refrigerant circuit

l

System and unit safety fault messages

Display/Print Keys for display of:

l

Chilled liquid and ambient air temperatures

l

System pressures (each circuit)

l

Operating hours and starts (each compressor)

l

Load and unload timers and cooling demand

l

Liquid pump, evaporator heater and condenser fan

status

Print calls up to the liquid crystal display:

l

Operating data for the systems

l

History of fault shutdown data for up to the last six fault

shutdown conditions

An RS-232 port, in conjunction with this press-to-print

button, is provided to allow hard copy print-outs via a

separate printer.

Entry Keys

l

To program and modify system values

Setpoints Keys for programming:

l

Chilled liquid temperature setpoint and range

l

Remote reset temperature range

l

Set daily schedule/holiday for start/stop

l

Manual override for servicing

l

Cut-outs for low ambient temperature, low liquid

temperature, high discharge pressure and low

suction pressure

l

Number of compressors and anti-recycle timer

(compressor start cycle time)

Unit Keys

l

To set time and unit options

Unit ON/OFF switch

l

To activate or deactivate the unit

The microprocessor control system is capable of

displaying the following:

l

Return and leaving liquid temperature

l

Low leaving liquid temperature cutout setting

l

Low ambient temperature cutout setting

l

Ambient air temperature

l

Metric or Imperial data

l

Discharge and suction pressure cutout settings

l

System suction pressures

l

System discharge pressures

l

Anti-recycle timer status

l

Anti-coincident system start timer condition

l

Compressor run status

l

No cooling load condition

l

Day, date and time

l

Daily start/stop times

l

Holiday status

l

Automatic or manual system lead/lag control

l

Lead system definition

l

Compressor starts & operating hours (each

compressor)

l

Evaporator heater and fan operation

l

Run permissive status

l

Number of compressors running

l

Load & unload timer status

l

Water pump status

l

Liquid Temperature Reset via a YORK ISN DDC or

Building Automation System (by others)

Provision shall be included for optional remote

chilled/hot liquid temperature reset.

(09/03)

6

-

4

035B09012-100 Rev. 4

Summary of Contents for YCAA B 120

Page 2: ......

Page 16: ...This Page Left Intentionally Blank 09 03 2 6 035B09012 100 Rev 4 ...

Page 28: ...This Page Left Intentionally Blank 09 03 4 10 035B09012 100 Rev 4 ...

Page 36: ...Page Left Intentionally Blank 09 03 6 6 035B09012 100 Rev 4 ...

Page 40: ...Page Left Intentionally Blank 09 03 7 4 035B09012 100 Rev 4 ...

Page 68: ...Notes 09 03 11 2 035B09012 100 Rev 4 ...

Page 69: ...Notes 09 03 035B09012 100 Rev 4 11 3 ...