1133383-YIM-A-1014

30

Johnson Controls Unitary Products

For satisfactory operation, LP gas pressure must be 10.5 inch

W.C. at the unit under full load. Maintaining proper gas

pressure depends on three main factors:

1.

The vaporization rate which depends on the temperature of

the liquid and the “wetted surface” area of the container(s).

2.

The proper pressure regulation. (Two-stage regulation is

recommended).

3.

The pressure drop in the lines between regulators and

between the second stage regulator and the appliance.

Pipe size required will depend on the length of the pipe run

and the total load of all appliances.

Complete information regarding tank sizing for vaporization,

recommended regulator settings, and pipe sizing is available

from most regulator manufacturers and LP gas suppliers.

Check all connections for leaks when piping is completed using

a soap solution.

NEVER USE A FLAME.

Vent And Combustion Air

Venting slots in the heating compartment access panel remove

the need for a combustion air hood. The gas heat flue exhaust

is routed through factory installed exhaust piping with screen. If

necessary, a flue exhaust extension may be installed at the

point of installation.

Options/Accessories

Electric Heat

Electric heaters are available as factory-installed options or

field-installed accessories. Refer to electric heat instructions for

installation. These heaters mount in the heat compartment with

the heating elements extending into the supply air chamber. All

electric heaters are fused and intended for use with single point

power supply.

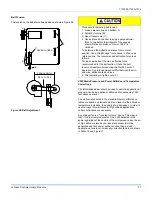

Smoke Detectors

The factory-installed smoke detector will shut down operation of

the unit by interrupting power to the UCB when smoke is

detected within its mounting compartment. The smoke detector

option is available for both supply and/or return air configura-

tions. Be aware that the supply air configuration has the sensor

component mounted in the blower section, with its control mod-

ule mounted in the return air compartment.

The detector must be tested and maintained on a regular basis

according to NFPA 72 requirements and cleaned at least once

a year. For specific troubleshooting and maintenance

procedures, please refer to the smoke detector's installation

instructions which accompanies the unit.

Motorized Outdoor Damper

The Motorized Outdoor Damper can be a factory installed

option or a field installed accessory. If factory installed, refer to

the instructions included with the outdoor air hood to complete

the assembly. Field installed Motorized Outdoor Damper

accessories include complete instructions for installation.

LP gas is an excellent solvent and will quickly dissolve

white lead and most standard commercial compounds. A

special pipe dope must be used when assembling

wrought iron or steel pipe for LP. Shellac base

compounds such as Gaskolac or Stalastic, and

compounds such as Rectorseal #5, Clyde’s, or John

Crane may be used.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warning exactly could result

in serious injury, death or property damage.

Never test for gas leaks with an open flame. use a

commercially available soap solution made specifically

for the detection of leaks to check all connections. A fire

or explosion may result causing property damage,

personal injury or loss of life.

The use of duct smoke detectors have specific limitations

as established by the National Fire Protection

Association. Duct smoke detectors are; NOT a substitute

for an open area smoke detector, NOT a substitute for

early warning detection, and NOT a replacement for a

building's regular fire detection system. Refer to NFPA

Code 72 and Standard 90A for additional information.

Factory-installed smoke detectors may be subjected to

extreme temperatures during "off" times due to outside air

infiltration. These smoke detectors have an operational

limit of -4°F to 158°F. Smoke detectors installed in areas

that could be outside this range will have to be relocated to

prevent false alarms.

To assure adequate airflow reaches the smoke detector's

sensor, make sure that the holes of the sampling tube

face into the air stream, and that the far-end of the

sampling tube is sealed with the plastic end cap.

In addition, the unit's supply airflow must be adjusted to

provide a pressure differential across the smoke

detector's sampling and exhaust ports of at least 0.01

inches of water and no more than 1.11 inches of water, as

measured by a manometer.