661693-UIM-E-1212

4

Johnson Controls Unitary Products

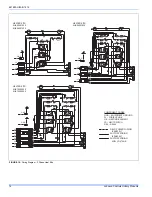

HORIZONTAL CONVERSION

These air handler units are supplied ready to be installed in a upflow

and right hand horizontal position. If unit requires left hand positioning,

the unit must have the coil assembly repositioned.

1.

Remove blower, coil, and filter access panels.

For horizontal left installations, follow steps 2 - 8.

2.

Remove tubing connection panel.

3.

Slide coil assembly out of air handler.

4.

Rotate cabinet 180º so blower outlet is facing down.

5.

Re-install coil assembly on coil support bracket.

6.

Re-attach tubing connection panel.

7.

For horizontal applications, rotate air handler 90º into desired orien-

tation.

8.

Re-position drain plugs as necessary based on air handler orienta-

tion.

9.

Re-position and replace access panels.

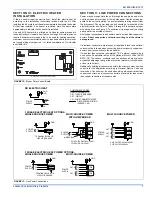

SUCTION FEEDER TUBECONDENSATE DEFLECTOR

UPFLOW

No action required. See Figure 4.

HORIZONTAL LEFT OR RIGHT

Use an appropriate tool to pry out water deflector with two or three s-

clips from the vertical drain pan, see Figure 4. Relocate the deflector

with s-clips on the Horizontal Drain Pan lined up to the coil support

bracket. See Figure 5. This positions the deflector below the feeder

tubes to channel the condensate to the drain pan.

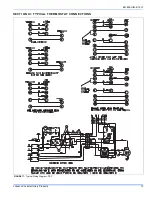

DUCT FLANGES

Four flanges are provided to attach ductwork to the furnace. These

flanges are rotated down for shipment. In order to use the flanges,

remove the screw holding an individual flange, rotate the flange so it is

in the upward position and reinstall the screw then repeat this for all 4

flanges. See Figure 7.

If the flanges are not used, they must remain in the rotated down posi-

tion as shipped.

FIGURE 3:

Typical Installation

For both horizontal applications, the condensate deflector should be

positioned as shown in Figure 2.

Conversion must be made before brazing the refrigerant connections

to the coil.

FIGURE 4:

Condensate Deflector on Vertical Drain Pan

UPFLOW

HORIZONTAL RIGHT

HORIZONTAL LEFT

HEAT

HEA

T

HEA

T

NOTICE

NOTICE

CONDENSATE

DEFLECTOR

S-CLIPS (3)

VERTICAL

DRAIN PAN

The condensate deflector should be installed in the s-clip section

which is inside the drain pan edge. See Figure 6.

FIGURE 5:

Condensate Deflector on Horizontal Drain Pan Edge

FIGURE 6:

S-Clip Installation

FIGURE 7:

Duct Attachment

NOTICE

S-CLIPS ON HORIZONTAL PAN

FEEDER

TUBES

CONDENSATE

DEFLECTOR

CONDENSATE

DEFLECTOR

S-CLIP

DRAIN PAN

WALL

FACTORY

INSTALLED

FOR DUCT ATTACHMENT,

IF NEEDED

Summary of Contents for 41HP AHR18B

Page 1: ......