WARNING: Solvent cements are flammable and must

be used in well-ventilated areas only. Keep them away

from heat, sparks and open flames (including pilots).

Do not breathe vapors and avoid contact with skin and

eyes.

6. All joints must be made to provide a permanent, air-tight,

water-tight seal.

7. Support the combustion air and vent piping such that it is

angled 1/4" per linear foot so that condensate will flow back

toward the furnace. Piping should be supported with pipe

hangers to prevent sagging. Maximum spacing between

hangers is five (5) feet, except SDR-PVC piping, where

maximum spacing is three (3) feet.

8. Seal around the openings where the combustion air and

vent piping pass through the roof of side wall.

CAUTION: Vent piping must be insulated with 1/2"

Armaflex insulation if it will be subjected to freezing

temperatures such as routing through unheated ar-

eas or through an unused chimney.

CAUTION: When combustion air pipe is installed

above a suspended ceiling, the pipe must be insulated

with 1/2" Armaflex type insulation. The combustion air

pipe should also be insulated when it passes through

a warm, humid space.

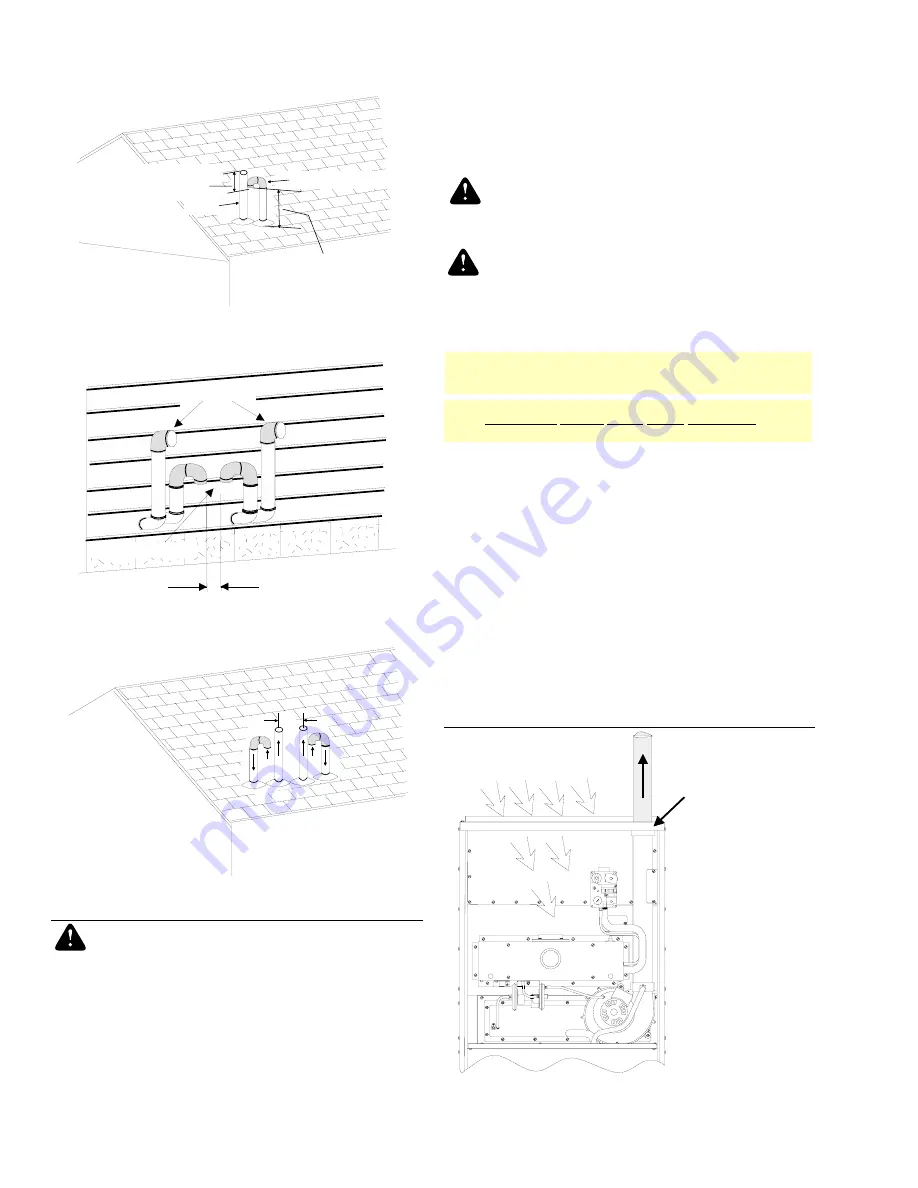

This type installation will use combustion air from within the

space surrounding the furnace. This may be from within the

space in a non-confined location or it may be brought into the

furnace area from outdoors. It is not directly ducted into the

furnace. A single, properly sized pipe from the furnace vent

connector to the outdoors must be provided.

For upflow models combutsion air is brought into the furnace

through the unit top panel opening. It is not necessary to install a

pipe into the intake collar on top of the burner box. For details refer

to Figure 22.

For downflow/horizontal models combustion air is brought into

the furnace through the unit side panel openings.

For downflow/horizontal models, remove a minimum of two gas

piping knockouts for combustion air access. It is not necessary

to install a pipe into the intake collar on bottom of the burner

box. For details, refer to Figure 23.

MAINTAIN 12" MINIMUM

CLEARANCE ABOVE HIGHEST

ANTICIPATED SNOW LEVEL.

MAXIMUM OF 24" ABOVE ROOF

COMBUSTION AIR

VENT

12" VERTICAL SEPARATION

BETWEEN COMBUSTION

AIR AND VENT

FIGURE 19 - VERTICAL TERMINATION

VENT

COMBUSTION AIR

2"

FIGURE 20 - DOUBLE SIDEWALL TERMINATION

6"

FIGURE 21 - DOUBLE ROOFTOP TERMINATION

METHOD

TWO:

ONE

PIPE

SYSTEM

NOTE: Vent pipe must be sloped 1/4" per foot to allow conden-

sate to flow back to the furnace.

M

P

C

1

3

2

O

FF

O

N

COMBUSTION AIR

VENT PIPE

CEMENTS

INTO SOCKET JUST

UNDER TOP PANEL

FIGURE 22 - UPFLOW VENT PIPE CONNECTION

650.75-N4U

14

Unitary Products Group