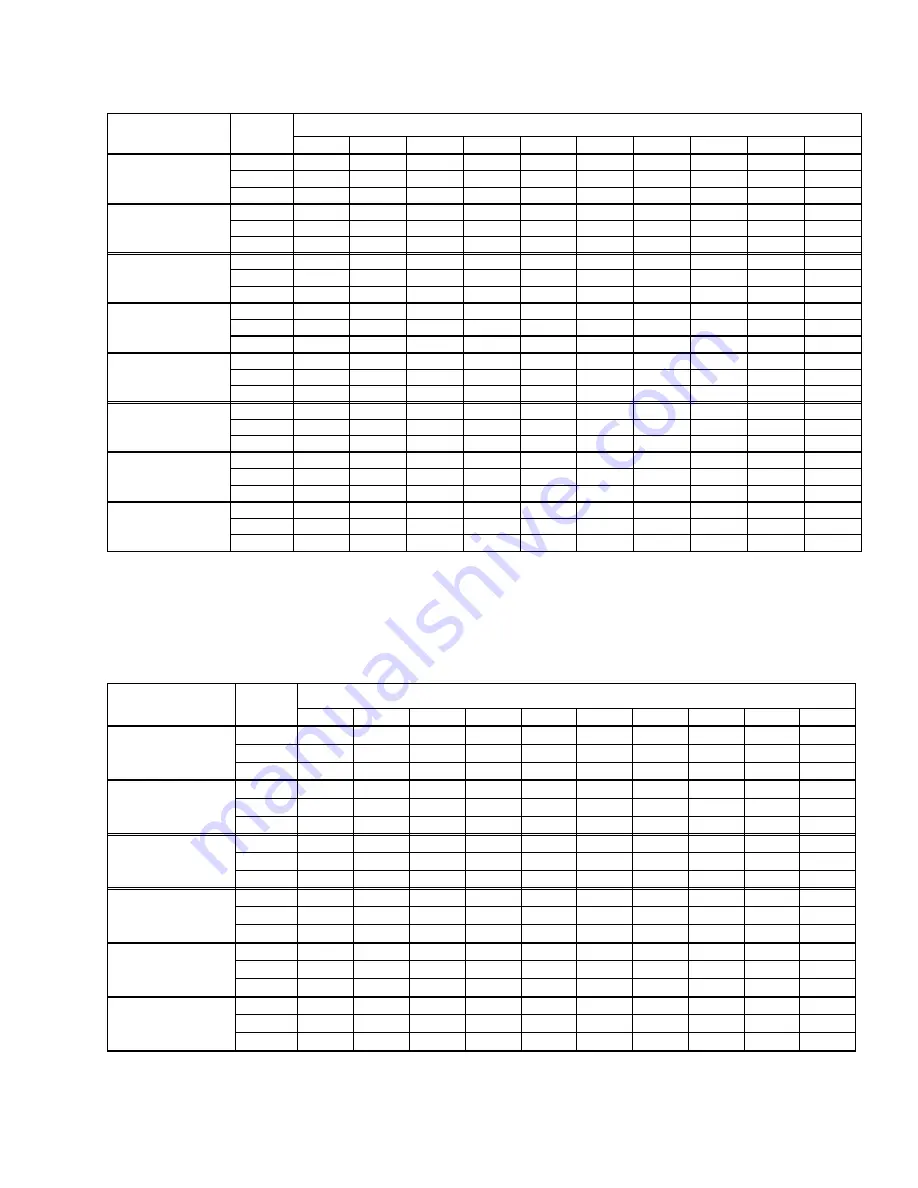

AIRFLOW DATA - UPFLOW MODELS

MODEL

SPEED

TAP

EXTERNAL STATIC PRESSURE, INCHES WC

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

40 / 37 / 800 / A

HI

1182

1164

1136

1101

1063

1018

967

904

824

724

MED

954

938

919

899

876

838

798

744

686

588

LOW

650

643

634

620

602

577

542

494

440

335

60 / 55 / 1200 / B

HI

1567

1552

1532

1517

1484

1441

1384

1315

1243

1166

MED

1175

1173

1169

1159

1144

1126

1089

1039

985

910

LOW

881

879

871

861

842

826

795

756

724

664

80 / 75 / 1200 / B

HI

1603

1579

1558

1522

1485

1433

1380

1311

1233

1139

MED

1250

1230

1210

1190

1160

1125

1083

1029

955

889

LOW

925

904

891

873

845

829

793

761

685

618

80 / 75 / 1600 / C

HI

2024

1960

1911

1855

1780

1698

1627

1540

1458

1387

MED

1479

1471

1465

1452

1429

1393

1359

1300

1238

1163

LOW

—

—

1210

1208

1198

1175

1149

1110

1052

982

100 / 95 / 2000 / C

HI

2272

2200

2128

2061

1984

1890

1810

1710

1627

1519

MED

1980

1933

1887

1838

1769

1701

1626

1535

1426

1328

LOW

1573

1546

1526

1498

1464

1417

1359

1290

1222

1132

120 / 112 / 2000 / D

HI

2281

2215

2144

2065

2002

1903

1820

1720

1618

1505

MED

1945

1902

1849

1794

1738

1675

1604

1535

1426

1343

LOW

1507

1485

1463

1433

1398

1358

1305

1249

1172

1095

Airflow expressed in standard cubic feet per minute.

NOTES: 1. Air filter installed. All filters must be high velocity, cleanable type.

2. Motor voltage at 115 V.

MODEL

SPEED

TAP

EXTERNAL STATIC PRESSURE, INCHES WC

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

40 / 37 / 800 / A

HI

1051

1005

977

985

835

757

665

450

—

—

MED

900

887

851

810

752

693

609

403

—

—

LOW

—

581

577

569

542

468

—

—

—

—

60 / 55 / 1000 / B

HI

1220

1200

1190

1152

1115

1065

1012

950

872

771

MED

—

—

920

915

900

880

842

803

740

650

LOW

—

—

725

729

715

700

681

653

600

525

80 / 75 / 1200 / B

HI

1431

1395

1355

1317

1263

1226

1165

1101

1029

937

MED

1188

1076

1065

1046

1023

994

955

906

842

752

LOW

832

823

811

805

794

766

742

672

624

561

80 / 75 / 1600 / C

HI

1879

1837

1794

1740

1688

1627

1559

1485

1406

1314

MED

—

1379

1374

1348

1340

1313

1271

1232

1158

1978

LOW

—

—

—

1196

1181

1141

1095

1053

1001

936

100 / 95 / 1400 / C

HI

1742

1672

1602

1519

1433

1348

1232

1098

934

766

MED

—

1390

1360

1320

1265

1176

1082

965

810

656

LOW

—

—

1097

1061

1035

1000

927

830

708

574

100 / 95 / 2000 / C

HI

2300

2229

2168

2100

2026

1939

1855

1758

1661

1546

MED

1937

1897

1855

1808

1737

1673

1597

1511

1425

1305

LOW

1579

1564

1533

1481

1461

1415

1350

1291

1205

1093

120 / 112 / 2000 / D

HI

2366

2298

2226

2153

2065

1988

1890

1808

1712

1600

MED

2000

1961

1920

1874

1821

1757

1685

1606

1510

1430

LOW

1588

1578

1545

1525

1492

1455

1399

1340

1260

1163

140 / 130 / 2000 / D

HI

2343

2275

2204

2132

2047

1968

1871

1791

1695

1585

MED

1981

1942

1901

1856

1803

1740

1669

1591

1490

1416

LOW

1575

1562

1530

1510

1477

1440

1386

1327

1248

1152

Airflow expressed in standard cubic feet per minute.

NOTES: 1. Return air is through side opposite motor (left side).

2. Air flows above 1800 CFM require either return from two sides or one side plus bottom.

3. Air filter installed. All filters must be high velocity, cleanable type.

4. Motor voltage at 115 V.

AIRFLOW DATA - DOWNFLOW/HORIZONTAL MODELS

650.75-N4U

28

Unitary Products Group