After determining the best orientation, lay the unit on top of the

shipping carton to protect the finish. The appropriate electrical

knock-outs for power wiring, control wiring and gas piping

should be removed at this time.

For horizontal application, return air may enter through the end

only. Return air may not be connected into the rear panel

of the unit.

Horizontal Filters

All filters and mounting provision must be field supplied. Fil-

ters(s) may be located in the duct system external to the

furnace or in a return filter grille(s).

ATTIC INSTALLATION

This appliance is design certified for line contact for furnaces

installed horizontally. The intersection of the furnace top and

sides form a line. This line may be in contact with combustible

material. However, refer to "Venting" and "Clearances" in this

manual for additional information.

Secure a platform constructed of plywood or other building

material to the floor joists. Refer to Figure 6 for details.

NOTE: The unit must be elevated to allow clearance

for the condensate trap and drain pipe.

CAUTION: If this furnace is installed over a finished

space a condensate safety pan must be installed.

WARNING: When a furnace is installed in an attic or

other insulated space, keep all insulating materials at

least 12" away from furnace and burner combustion

air openings.

NOTE: See crawl space installation for suspending

the furnace in attic installations.

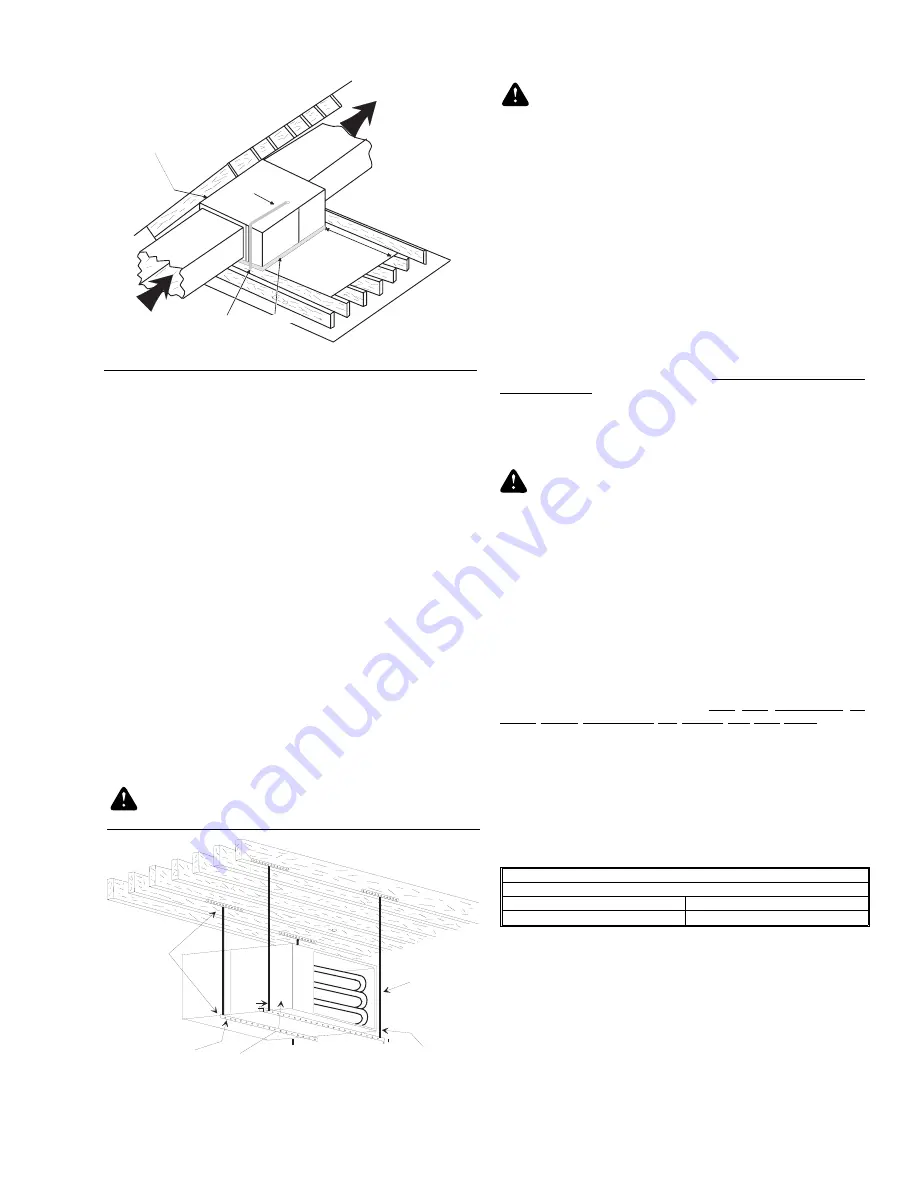

CRAWL SPACE INSTALLATION

The furnace can be hung from floor joists or installed on

suitable blocks or pad. Blocks or pad installations shall provide

adequate height to ensure the unit will not be subject to water

damage.

When suspending the furnace from rafters for floor joists using

rod, pipe or straps, refer to Physical Data (Page 4 or 5) for

furnace weights to determine suitable means of suspension.

Angle supports should be placed at the supply air end and near

the blower deck. Refer to Figure 7. Do not support at return

air end of unit.

Units may also be suspended by using straps or other material

at the same location. All four suspension points must be level

to ensure quiet furnace operation.

CAUTION: In any application where temperatures

below freezing are possible, refer to Page 6, "Below

Freezing Locations."

GAS PIPING

The gas supply must be installed in accordance with the current

National Fuel Gas Code, ANSI Z223.1 (in the U.S.) or

CAN/CGA-B149.1 or .2 (in Canada) installation codes and all

applicable local and utility requirements. All pipe and fitting

material, pipe size and installation procedures must comply

with the appropriate code. Some utilities may require larger

pipe sizes than shown in the code. Gas piping may be con-

nected from either side of the furnace. Each side of the unit has

two gas pipe entry knockouts.

For downflow/horizontal models, plan your combustion air

piping before determining the correct gas pipe entry. Use 90

degree service elbow(s), or short nipples and conventional 90

degree elbow(s) to enter through the cabinet access holes.

NOTE: An accessible manual shutoff valve must be installed

upstream of the furnace gas controls and within 6 feet of

the furnace.

The installation of a ground joint union and drop leg are

required. Refer to Figure 8. Maximum and minimum supply gas

pressures are shown below:

NOTE: A 1/8" NPT plug is included in the inlet side of the gas

valve for measuring incoming gas pressure.

The furnace must be isolated from the gas supply piping

system by closing its individual external manual shutoff valve

during any pressure testing of the gas supply piping system at

pressures equal to or less than 1/2 psig (3.48 kPa).

The furnace and its individual shutoff valve must be discon-

nected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig

(3.48 kPa).

INLET GAS PRESSURE

Natural Gas

Minimum

4.5 In. W.C

Maximum

13.8 In. W.C.

G A S P I P I N G

S E D I M E N T T R A P

3 0 " M I N

W O R K A R E A

R E T U R N A I R

S U P P L Y A I R

L I N E C O N T A C T O N L Y P E R M I S S I B L E

B E T W E E N L I N E S F O R M E D B Y T H E

I N T E R S E C T I O N O F F U R N A C E T O P

A N D T W O S I D E S A N D B U I L D I N G

J O I S T S , S T U D S O R F R A M I N G

S A F E T Y P A N

FIGURE 6 - TYPICAL ATTIC INSTALLATION

S U P P O R T

R O D

A N G L E I R O N

B R A C K E T

6 " M I N B E T W E E N

R O D & F U R N A C E

1 " M A X B E T W E E N

R O D & F U R N A C E

1 " M A X B E T W E E N

R O D & F U R N A C E

FIGURE 7 - TYPICAL FURNACE INSTALLATION

USING SUSPENSION MATERIALS

650.75-N4U

Unitary Products Group

9