JOHNSON CONTROLS

57

SECTION 3 - MAINTENANCE

FORM 102.20-OM2

ISSUE DATE: 6/01/2015

3

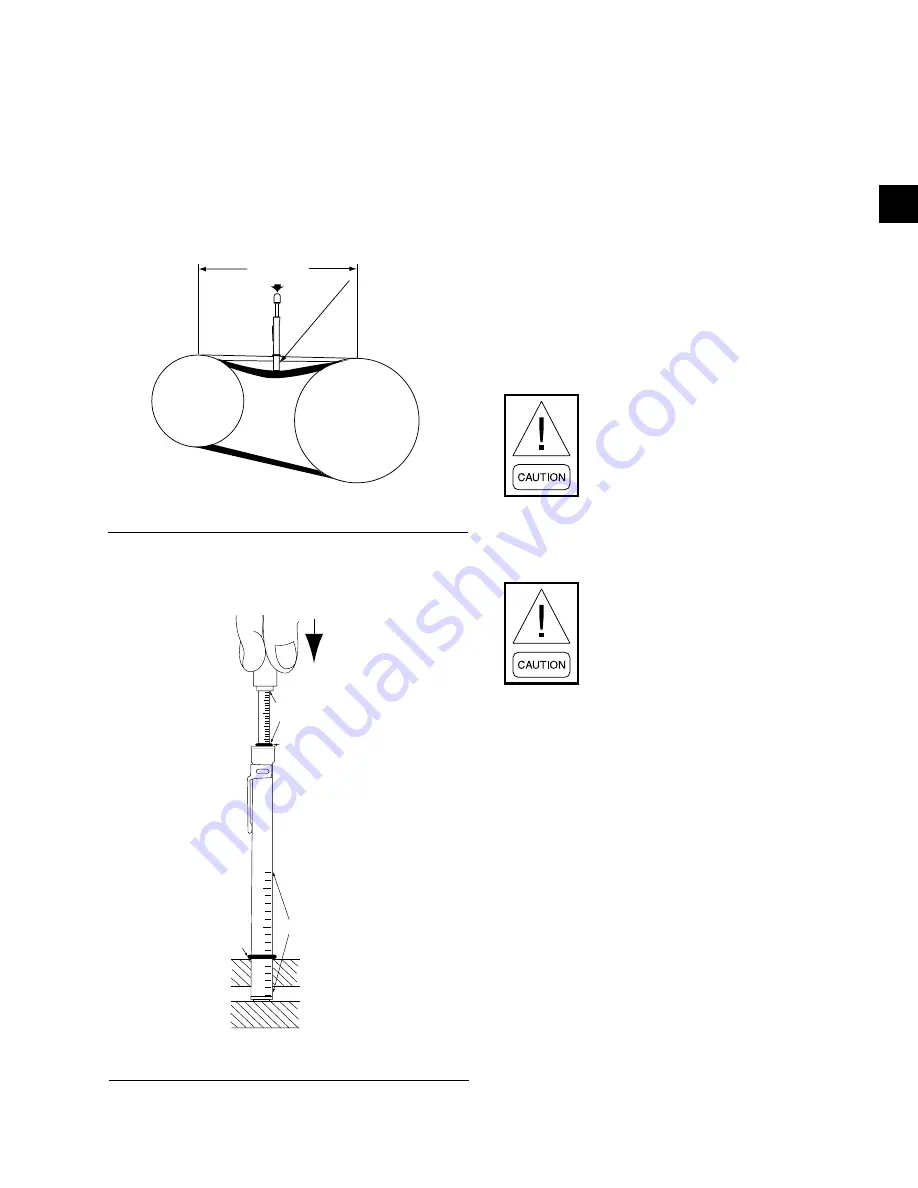

Checking Belt Tension

Check the belt tension. It is normal for belts to loosen

after start-up or replacement. The new belt will

run in

or

take a set

by seating slightly deeper into the grooves

of the sheaves. Recheck tension after one day, and

again after three days.

1. Measure the belt span as shown in

.

BELT SPAN

SPAN LENGTH

DEFLECTION

FIGURE 46 -

BELT TENSIONING

LD05627a

2. Position bottom of the large O-ring on the span

scale at the measured belt span as shown in

.

15 20 25 30

Small

O-ring

50

100

15

0

Span

Scale

Deflection

Force

Scale

INCHES of SPAN

Large

O-ring

FIGURE 47 -

BELT TENSIONING GAUGE

LD05628a

3.

Set the small O-ring on the deflection force scale

to zero.

4. Place the tension gauge squarely on one belt at

the center of the belt span. Apply a force on the

plunger and perpendicular to the belt span until

the bottom of the large O-ring is even with the top

of the next belt or with the bottom of a straight

edge laid across the sheaves.

5. Remove the tension gauge and read the force ap-

plied from the bottom of the small O-ring on the

deflection force scale.

6. Compare the force you have applied with the

value given on the drive kit data tag as shown in

Never use excessive tension because this

could result in damaging the bearing,

motor pulleys or motor base. Refer to the

drive label on the fan housing for specific

details on tension. Squealing belts during

starting is caused by slipping belts that are

not tensioned properly.

ALIGNING SHEAVES

An incorrectly aligned sheave can sub-

stantially shorten belt life or overload

blower and motor bearings, shortening

their life expectancy. A belt tensioned too

tightly can overload the motor electrically,

causing nuisance tripping of the motor

overloads and/or motor failure and/or

shaft failure.

Sheave alignment and parallelism of shafts is very

important. Proper alignment helps equalize the load

across the entire belt width, thereby reducing wear and

extending belt life.

shows how

to align a synchronous drive properly using a straight-

edge or shows how to use

a piece of string as shown in

After aligning the sheaves, check the rigidity of the

supporting framework. Shafts should be well support-

ed to prevent distortion and a resulting change in the

center distance under load. Do not use spring-loaded

or weighted idlers.