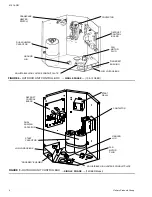

OUTDOOR UNIT

After the site has been selected, a solid base pad that will not

shift or settle should be provided. The base pad should not

come in contact with the foundation or side of the structure

because sound may be transmitted to the residence. The top

of the pad should be at least two inches above grade to give

sufficient height for defrost ice build up during freezing winter

temperatures. See Figure 2. The pad should be located far

enough away from the structure so the outdoor unit is not closer

than its minimum distances. See Figure 1. Set the outdoor unit

upon the pad with care to avoid damage.

CAUTION: Do not remove the protective caps or plugs from

the unit refrigerant connections until the refrigerant

lines are run and ready for final connection. If this

procedure is not observed, dirt and other particles

will get into the system and plug various orifices

and small tubes.

DISCHARGE LINE FILTER-DRIER

The 10, 12 and 14 SEER heat pumps have a solid core filter-

drier located in the discharge line. Due to its location in the

refrigerant circuit it uses a unique oversize capacity drier with

a high temperature binder.

NOTE: Replacement of the discharge line drier must be the

exact same as marked on the original factory drier. See

Source 1 for replacement drier.

Three phase unit filter dryers must be replaced by

exact same as listed below:

CAUTION: Failure to do so or using a substitute drier or a

granular type may result in damage to the equip-

ment.

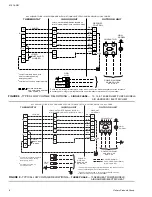

OUTDOOR THERMOSTATS

An outdoor thermostat (balance point) may be used with this

heat pump system. See last page of these instructions. Select

the proper location for mounting the outdoor thermostat (see

instructions packed with outdoor thermostat).

INDOOR UNITS

Install the indoor coil on the furnace or air handler according to

the installation instructions packed with each component.

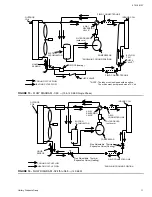

REFRIGERANT LINES (Sweat Fit)

The following steps are very important when setting up a

refrigeration system and need to be followed completely to

ensure that a strong, flexible and leak tight system is obtained.

The installation of the copper refrigerant tubing must be done

with care to obtain reliable, trouble-free operation.

1. Selection of proper refrigerant tubing grade and size

2. Refrigerant line routing, cutting and fitting

3. Insulating the vapor line

4. Proper preparation of joint connections.

5. Reassembling, cleaning and brazing the joint connections

6. Connecting the refrigerant lines to the indoor coil and

outdoor unit.

7. Pressure leak test all joints.

8. Evacuate refrigerant lines and indoor coil

9. Charging refrigeration system (See Tabular Data Sheet if

the line length is other than 15 feet).

Use only ACR grade copper tubing and keep ends sealed until

joints are made.

The correct diameters of the refrigerant lines are listed on the

unit nameplate.

For best performance, select routing of refrigerant lines for

minimum distance and fewest number of bends.

Determine the path that the refrigerant lines will follow.

Starting at either the indoor coil or the outdoor unit refrigerant

line connections, carefully measure, cut, de-burr and fit copper

refrigerant lines along the path previously determined.

NOTE: If it is necessary for bends to be formed in the vapor

line, the radius should not be less than 12 inches.

Cut ends of the copper tubing square.

Remove all burrs from tubing with a reamer, file or de-burring

tool.

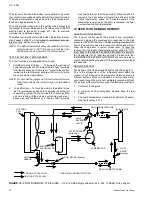

Whether the indoor coil is above of below the outdoor unit, the

vapor line should not be sloped for heat pump installations.

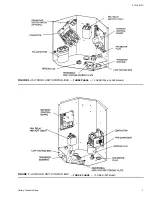

INSULATION OF VAPOR LINE

Insulate vapor line with 3/8" closed cell insulation.

Slide tubing insulation onto the vapor line so that it is covered

completely from the indoor coil to the outdoor unit. Be sure that

the tubing is capped before sliding on insulation.

It is not necessary to insulate the liquid line.

NOTE: In areas of extreme temperatures and humidity, addi-

tional insulation may be required to prevent excessive

condensation and loss of capacity.

Do not insulate liquid line and vapor line together. Liquid line

should not be in contact with the vapor line. See Figure 3.

BOTTOM OF COIL SHOULD

BE HIGER THAN AVERAGE

SNOWFALL FOR THE AREA

DEFROST ICE BUILD-UP

IN FREEZING WINTER

TEMPERATURE

FIGURE 2 - SNOW AND ICE CONSIDERATIONS

INSTALLATION

Source 1 Part No.

Discharge Line Drier

Apply with (10 SEER)

1 & 3 Phase Models:

026-11913-700

036

026-13486-700

048

026-13455-900

060

515.16-N3Y

Unitary Products Group

3