116

YORK INTERNATIONAL

This safety is activated after 3 minutes of operation.

Oil pressure must be less than 4.4 bar (65 PSID) for

R-22 models as long as the compressor continues to

run.

Low Oil Differential Pressure Cutout:

The Low Oil Pressure Differential Safety assures the

compressor receives proper lubrication by monitoring

the differential between oil pressure returning to the

compressor and suction pressure. Lack of a differential

indicates that the compressor is not pumping and no oil

is being pumped through the compressor to lubricate

the bearings and rotors.

This type of oil failure will not be picked up by the

High Oil Differential Safety since no flow will cause

the differential through the oil piping to drop to zero.

EXAMPLE:

For ambients above 10°C (50°F), the Low Oil Differen-

tial Safety is activated after 1 minute of compressor op-

eration when the oil pressure differential must be greater

than 0.7 bar (10 PSID). After 2 minutes it must be greater

than 1.4 bar (20 PSID); after 3 minutes, 2 BAR (30 PSID);

after 4 minutes, 2.7 bar (40 PSID); and from 5 minutes

of operation and onwards, oil pressure must remain higher

than 3.4 bar (50 PSID) or the system will be shut down.

For lower ambients, the linear ramp times are as follows:

AMBIENT TEMP

RAMP TIME

>10°C

(50°F)

5 Minutes

>7°C

(45°F)

6 Minutes

>4°C

(40°F)

7 Minutes

>2°C

(35°F)

8 Minutes

>-1°C

(30°F)

9 Minutes

<= -1°C

(30°F)

10 Minutes

High Oil Temperature Cutout:

This safety assures oil temperature does not exceed a

safe operating temperature which affects compressor

lubrication. Typical oil temperature during normal op-

eration will be approximately 54 - 66°C (130 - 150°F).

The High Oil Temperature Safety is activated after 2

minutes of compressor operation, after which if oil tem-

perature is above 107°C (225°F) for more than 3 sec-

onds, the compressor will shut down.

Low Suction Pressure Cutout:

The Low Suction Pressure Cutout aids in protecting

the evaporator from damage due to ice build up caused

by operation at low refrigerant charge or restricted re-

frigerant flow. A number of transient timer features pre-

vent nuisance trips during start-up, compressor load-

ing, etc. The Low Suction Pressure Safety is program-

mable (see Section 8.2 / Page 140, Low Suction Pres-

sure Cutout for more details).

The suction pressure cutout is ignored for the first 45

seconds of operation. During the next 180 seconds of

running, suction pressure may be lower than the cut-

out, but must be greater than:

SP Cutout =

Programmed Cutout * (run Time - 25)

25

This cutout value increases with time until after 225

seconds it equals the programmed cutout value. If suc-

tion pressure falls below the calculated cutout value

before 225 seconds of run time, the system will be shut

down.

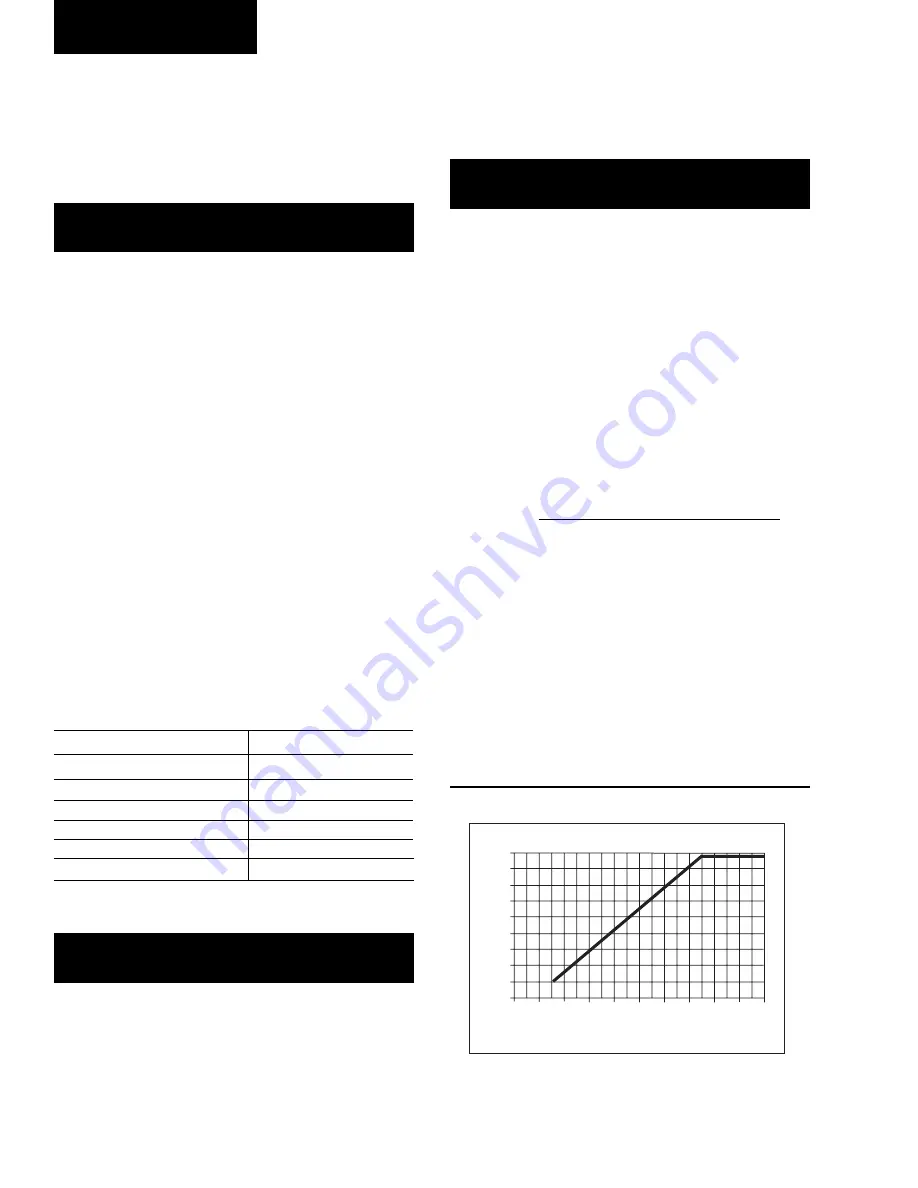

The following graph shows a typical programmed suc-

tion pressure cutout of 3 bar (44 PSIG) and its change

from time = 0 sec of compressor run time to 225 sec-

onds of compressor run time.

S Y S

#

L O W

S U C T

P R E S S

S Y S

#

L O W

S U C T

P R E S S

S Y S

#

L O W

O I L

D I F F

S Y S

#

L O W

O I L

D I F F

S Y S

#

H I G H

O I L

T E M P

S Y S

#

H I G H

O I L

T E M P

Suction Pressure Cutout With

44 PSIG Programmed Cutout

LD03525

0

30

60

90

120

150

180

210

240

270

310

45

40

35

30

25

20

15

10

5

0

Run Time (seconds)

Suction Pressure Cutout

FIG. 50 – SUCTION PRESSURE CUTOUT

Micro Panel Contents

Summary of Contents for eco2 YCAS0425EB

Page 26: ...26 YORK INTERNATIONAL This page intentionally left blank Product Description ...

Page 49: ...49 YORK INTERNATIONAL FORM 201 18 NM8 This page intentionally left blank 7 ...

Page 60: ...60 YORK INTERNATIONAL FIG 20 CONTINUED ELEMENTARY DIAGRAM Technical Data ...

Page 65: ...65 YORK INTERNATIONAL FORM 201 18 NM8 WIRING DIAGRAM WYE DELTA START LD03229 FIG 23 CONT D 7 ...

Page 66: ...66 YORK INTERNATIONAL FIG 23 CONTINUED ELEMENTARY DIAGRAM Technical Data ...

Page 68: ...68 YORK INTERNATIONAL FIG 24 POWER PANEL FRONT INSIDE VIEW WYE DELTA START Technical Data ...

Page 71: ...71 YORK INTERNATIONAL FORM 201 18 NM8 LD03282 LD03283 LD03284 FIG 27 DETAIL A 7 ...

Page 74: ...74 YORK INTERNATIONAL FIG 32 DETAIL B Technical Data LD03285 ...

Page 75: ...75 YORK INTERNATIONAL FORM 201 18 NM8 FIG 33 DETAIL C 7 3 4 5 6 7 8 5 6 3 4 7 8 9 10 LD06841 ...