105561-UIM-B-0605

Unitary Products Group

23

NOTES:

1. Airflow expressed in standard cubic feet per minute (CFM) and in cubic meters per minute (m

3

/min).

2. Return air is through side opposite motor (left side).

3. In order to stay within the velocity rating the filters, airflows above 1800 CFM (50.97 m

3

/min) require either return from two sides or one side plus bottom.

4. Motor voltage at 115 V.

5. NR = Operation at this static pressure is not recommended.

FILTER PERFORMANCE

The airflow capacity data published in Table 16 represents blower per-

formance WITHOUT filters. To determine the approximate blower per-

formance of the system, apply the filter drop value for the filter being

used or select an appropriate value from the Table 17.

NOTE: The filter pressure drop values in Table 17 are typical values for

the type of filter listed and should only be used as a guideline.

Actual pressure drop ratings for each filter type vary between fil-

ter manufacturers.

* Washable Fiber Filters are the type supplied with furnace.

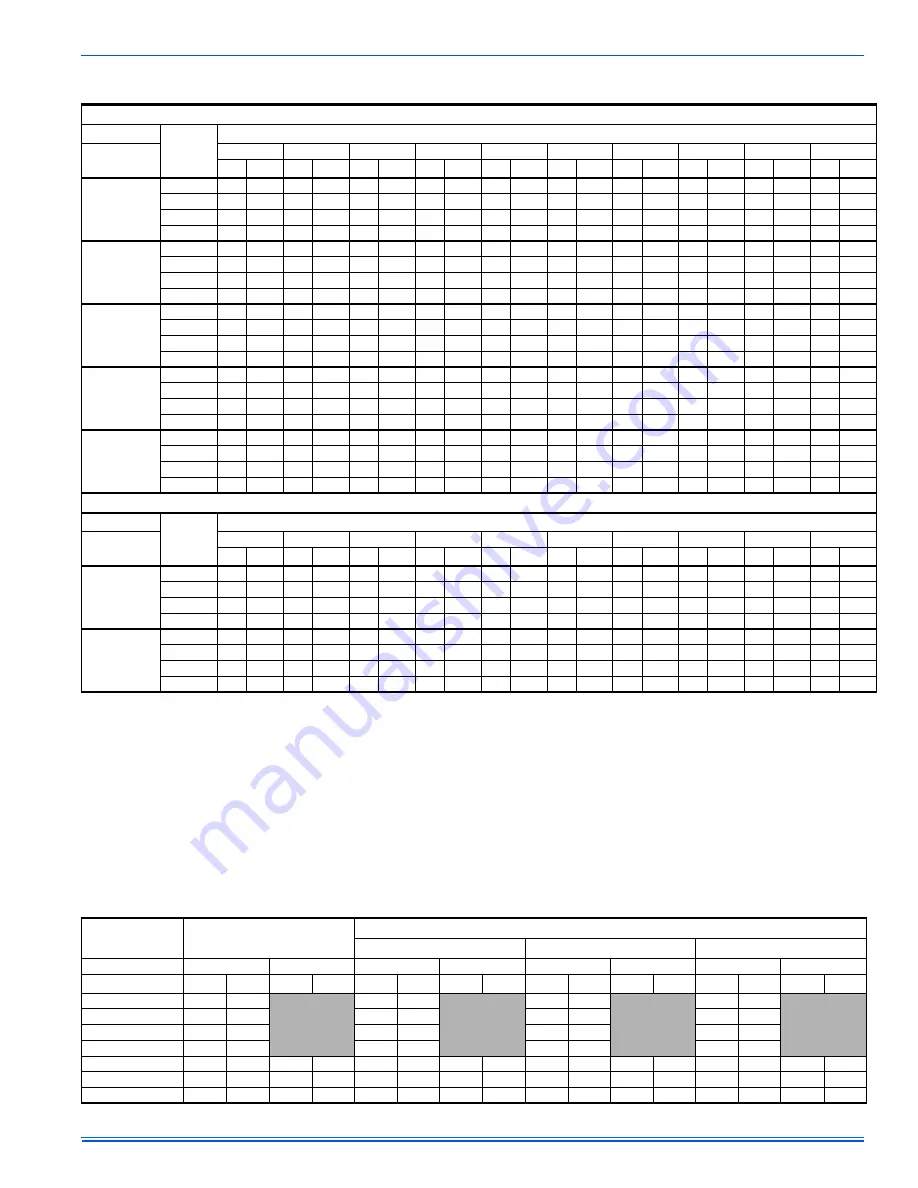

TABLE 15: Blower Performance CFM

AIRFLOW WITH BOTTOM OR ONE SIDE RETURN

MODELS

Speed

Tap

EXTERNAL STATIC PRESSURE, INCHES W.C. (kPa)

Input/

Airflow/cabinet

0.1 (0.025)

0.2 (0.050)

0.3 (0.075)

0.4 (0.099)

0.5 (0.124)

0.6 (0.149)

0.7 (0.174)

0.8 (0.199)

0.9 (0.224)

1.0 (0.249)

CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min

40/1200/A

HIGH 1635

46

1590

45

1535

43

1480

42

1415

40

1340

39

1280

36

1185

34

NR

NR

NR

NR

M-HI 1245 35

1225 35

1205 34

1185 34

1160

33

1110 31

1065

31

995

28

NR

NR

NR

NR

M-LO 1005 28

1000 28

995

28

975

28

955

27

925

26

885

25

825

23

NR

NR

NR

NR

LOW 775 22

770 22

765

22

750

21

725

21

680

19

655

19

620

18

NR

NR

NR

NR

60/1200/B

80/1200/B

HIGH 1650 47 1605 45 1570 44 1525 43 1465 41 1410 40 1350 38 1275 36 1170 33 1060 30

M-HI 1165 33 1185 34 1175 33 1165 33 1150 33 1140 32 1100 31 1050 30 970 27 875 25

M-LO 895 25 915 26 935 26 940 27 940 27 920 26 905 26 860 24 815 23 750 21

LOW 710 20 725 21 725 21 725 21 720 20 700 20 685 19 660 19 625 18 560 16

80/2000/C

100/2000/C

HIGH 2300

65

2210

63

2120

60

2020

57

1930

55

1830

52

1715

49

1595

45

1480

42

1350

39

M-HI 1950

55

1900

54

1830

52

1755

50

1680

48

1595

45

1500

42

1390

39

1270

36

1155

33

M-LO 1610

46

1545

44

1490

42

1440

41

1390

39

1315

37

1230

33

1155

33

1050

30

920

26

LOW 1325

38

1270

36

1225

35

1175

33

1105

31

1045

30

990

28

905

25

890

25

790

22

80/1600/C

100/1600/C

HIGH 1960 56 1955 55 1925 55 1890 54 1830 52 1765 50 1695 48 1615 46 1600 45 1485 42

M-HI 1565 44 1560 44 1560 44 1575 45 1545 44 1530 43 1475 42 1425 40 1365 39 1260 36

M-LO 1230 35 1275 36 1285 36 1300 37 1310 37 1300 37 1280 36 1245 35 1190 34 1070 30

LOW 930 26 945 27 965 27 975 28 975 28 975 28 975 28 950 27 910 26 850 24

120/2000/D

135/2000/D

HIGH 2560 72 2485 70 2410 68 2320 66 2220 63 2135 60 2035 58 1920 54 1785 51 1650 47

M-HI 2090 59 2050 58 1990 56 1970 56 1885 53 1820 52 1760 50 1675 47 1545 44 1405 40

M-LO 1695 48 1675 47 1665 47 1615 46 1565 44 1510 43 1460 41 1385 39 1285 36 1140 32

LOW 1175 33 1150 33 1135 32 1110 31 1085 31 1055 30 1005 28 980 28 970 27 845 24

AIRFLOW WITH TWO SIDE RETURNS OR WITH BOTTOM AND ONE SIDE RETURN

MODELS

Speed

Tap

EXTERNAL STATIC PRESSURE, INCHES W.C. (kPa)

Input/

Airflow/cabinet

0.1 (0.025)

0.2 (0.050)

0.3 (0.075)

0.4 (0.099)

0.5 (0.124)

0.6 (0.149)

0.7 (0.174)

0.8 (0.199)

0.9 (0.224)

1.0 (0.249)

CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min CFM m

3

/min

80/2000/C

100/2000/C

HIGH 2465

70

2380

67

2295

65

2195

62

2095

59

1995

56

1875

53

1760

50

1620

46

1470

42

M-HI 2085

59

2035

58

1960

55

1880

54

1800

51

1705

48

1605

45

1485

42

1360

39

1235

35

M-LO 1725

49

1625

46

1595

45

1540

44

1485

42

1405

40

1315

37

1235

35

1125

32

995

28

LOW 1420

40

1360

39

1310

37

1255

36

1180

33

1120

32

1070

30

970

27

950

27

845

24

120/2000/D

135/2000/D

HIGH 2615 74 2535 72 2450 69 2385 68 2285 65 2175 62 2075 59 1945 55 1825 52 1670 47

M-HI 2055 58 2045 58 2015 57 1985 56 1932 55 1855 53 1785 51 1730 49 1605 45 1470 42

M-LO 1690 48 1650 47 1620 46 1600 45 1570 44 1525 43 1470 42 1395 40 1300 37 1200 34

LOW 1345 38 1335 38 1335 38 1285 36 1250 35 1230 35 1180 33 1115 32 1010 29 850 24

TABLE 16: Filter Performance - Pressure Drop Inches W.C. and (kPa)

AIRFLOW

RANGE

MINIMUM OPENING SIZE

FILTER TYPE

DISPOSABLE

WASHABLE FIBERS*

PLEATED

1 Opening

2 Openings

1 Opening

2 Opening

1 Opening

2 Opening

1 Opening

2 Opening

Sq. in.

m

2

Sq. in.

m

2

In w.c.

Pa

In w.c.

Pa

In w.c.

Pa

In w.c.

Pa

In w.c.

Pa

In w.c.

Pa

0 - 750

230

.15

0.01

2.5

0.01

2.5

0.15

37

751 - 1000

330

.21

0.04

10

0.03

7.5

0.20

50

1001 - 1250

330

.21

0.08

20

0.07

17

0.20

50

1251 - 1500

330

.21

0.08

20

0.07

17

0.25

62

1501 - 1750

380

.25

658

.42

0.14

35

0.08

20

0.13

32

0.06

15

0.30

75

0.17

42

1751 - 2000

380

.25

658

.42

0.17

42

0.09

22

0.15

37

0.07

17

0.30

75

0.17

42

2001 & Above

463

.30

658

.42

0.17

42

0.09

22

0.15

37

0.07

17

0.30

75

0.17

42