FORM 160.49-M1

19

YORK INTERNATIONAL

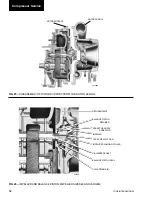

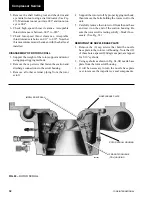

FIG. 27 –

CHECKING IMPELLER TOLERANCES

DETAIL A –

CHECKING RIM RUNOUT

(TOLERANCE - .003")

26347A

DETAIL B –

CHECKING EYE RUNOUT

(TOLERANCE - .002")

26346A

DETAIL C –

CHECKING AXIAL THRUST

00588VIP

REMOVING THE IMPELLER

(HA36 & HA41 Compressors) (See Figs. 29 & 30)

1. Before removing the impeller, measure and record

the following: (See Fig. 27) Position compressor so

that it is sitting on the correct horizontal plane to

assure correct readings.

a. Impeller rim Runout (Design 0.003" Max.)

b. Impeller eye Runout (Design 0.002" Max.)

c. High Speed Axial thrust (Design 0.008"

to 0.021")

d. Low Speed Axial Thrust (Design 0.011"

to 0.019")

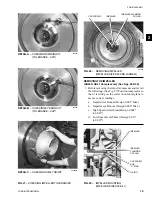

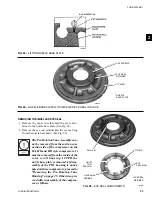

FIG. 28 –

REMOVING IMPELLER

(IMPELLER SIZES 46 AND LARGER)

26345A

CAP SCREWS

IMPELLER

IMPELLER CLAMPING

COLLAR

FIG. 29 –

IMPELLER MOUNTING

(IMPELLER SIZES 36 & 41)

IMPELLER

IMPELLER

CLAMPING

COLLAR

CAP SCREW

AND

“O” RING

O-RING

26439A

2