YORK INTERNATIONAL

34

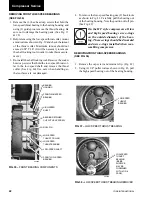

RE-ASSEMBLY OF NOZZLE BASE PLATE

1. 1. Install a new o-ring on the nozzle base plate.

(See Fig. 65)

2. Carefully turn the nozzle base plate over and insert

eyebolts into the (2) tapped holes.

3. Insert guide pins into (2) of the holes in the scroll

housing.

4. Using proper rigging methods, lower the nozzle base

plate over the guide pins and into position in the

scroll housing. Remove eyebolts and guide pins; in-

sert cap screws and tighten to specified torque in

Table 4.

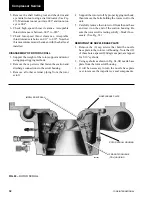

RE-ASSEMBLY OF SCROLL HOUSING

TO ROTOR SUPPORT

1. Using proper rigging methods, lift scroll housing as-

sembly into place on unit base.

2. Using new gaskets, re-connect suction and dis-

charge piping.

3. Insert guide pins into the scroll housing and install a

new gasket. Note that the gasket contains three

holes to clear the jacking screws in the rotor sup-

port. Be sure gasket is installed correctly. (See Fig.

68). Coat gasket with a mixture of oil and graphite.

On the HF style compressors this seal-

ing surface uses an o-ring instead of a

gasket. Coat the o-ring with a suitable

o-ring lubricant to secure o-ring into

groove during assembly.

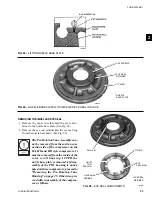

RE-ASSEMBLY OF THE EYE SEAL

(HA, HB, HD Style Compressors)

1. Inspect all parts before re-assembly. See

“Clean-

ing and Checking Wearing Parts”

, page 6. Re-

place with new parts as necessary.

2. Be sure the helical springs are securely locked in

pockets. Give each spring a clockwise twist to lock

it into place. Install a new o-ring in the eye seal

retainer.

3. Place the eye seal ring and retainer into position on

the nozzle base plate. Be sure the hole in the eye

seal ring fits over the roll pin in the nozzle base plate.

(See Fig. 66). Insert cap screws and tighten. Check

that the seal ring is free to “float”.

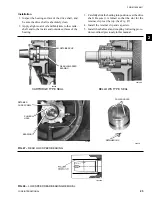

(HF Style Compressors)

This style compressor uses a flat spring

washer instead of the helical springs

used on the HA, HB, and HD style

compressors. (See Fig. 65 – HF Eye

Seal)

1. Inspect all parts before re-assembly. See

“Clean-

ing and Checking Wearing Parts”

, page 6. Re-

place with new parts as necessary.

2. Place flat spring washer into retainer and position

eye seal over spring washer.

3. Take complete eye seal assembly and position on

nozzle base plate. Insert cap screws and tighten.

Check that seal ring is free to “float”.

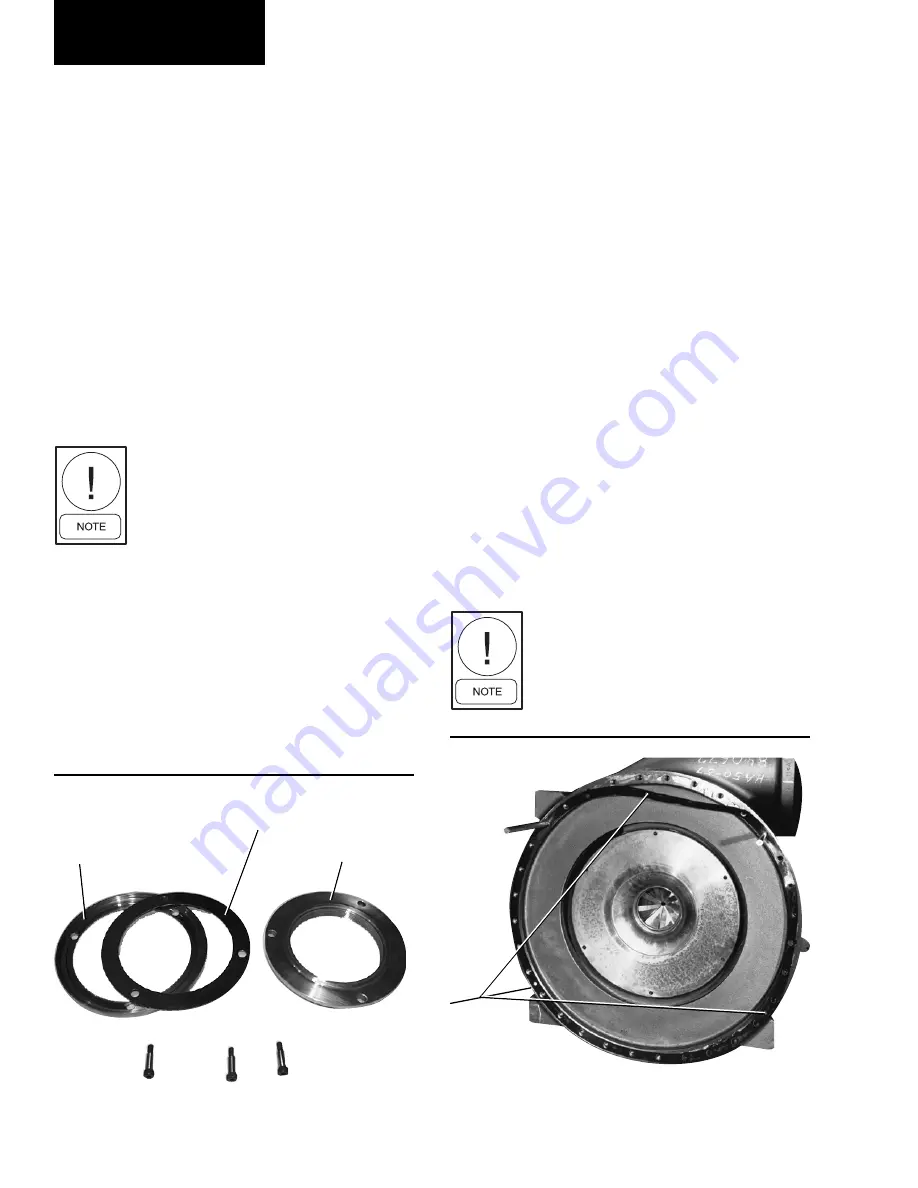

FIG. 68 –

SCROLL HOUSING READY FOR

RE-ASSEMBLY TO MOTOR SUPPORT

26301A

CLEARANCE

HOLES FOR

JACKING SCREWS

FIG. 67 –

HF EYE SEAL

Compressor Service

00592VIP

IMPELLER EYE

SEAL RETAINER

FLAT SPRING

WASHER

IMPELLER

EYE SEAL