YORK INTERNATIONAL

38

FORM 160.54-M1(503)

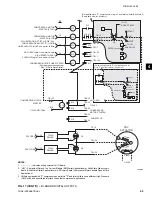

I / O Board

short from triac Gate to Triac terminal 2. A volt me ter

can be used to determine if a Triac is turned on or off.

Measure across the Triac; from Triac terminal 1 to Triac

terminal 2. When the Triac is turned off, the volt age will

be ap prox i mate ly 20 to 30VAC; when turned on, it will

be <10VAC.

The Pre-rotation Vanes Actuator is manufactured by

Barber-Coleman. This actuator has three windings; a

Field winding and two direction windings. One di rec tion

wind ing produces clockwise rotation, the other pro duc es

coun ter clock wise rotation. The 115VAC applied to the

Field Winding induces a 20 to 30VAC voltage into each

of the direction windings. The desired ro ta tion is pro-

duced by shorting the Actuator common ter mi nal to the

ap pro pri ate direction terminal, causing current to

fl

ow in

the di rec tion winding. As described above, Triacs con trol

the current through the open and close wind ings.

The Refrigerant Level Variable Ori

fi

ce Actuator on new

production chillers is manufactured by Belimo. This ac-

tu a tor has two windings; open and close. One wind ing

pro duc es clockwise rotation and one produces coun ter -

clock wise rotation. This actuator operates from 24VAC.

As described above, Triacs are turned on to al low cur rent to

fl

ow through the appropriate winding to produce the de sired

rotation. If the OptiView Control Center is retro

fi

t to an ex-

isting chiller, it could be equipped with a Barber-Coleman

Level Actuator that operates as de scribed above.

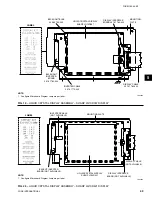

RELAY TIMING

Under Program control, the relays are energized and

de-energized producing contact operation as follows.

Unless otherwise noted, contact rating is 5 amps re sis tive

or 2 Amps inductive @ 250VAC.

K0 - Chilled Water Pump Starter (TB2-44/45)

Dry closure contacts. When the chiller is started, the Con-

tacts close 13 seconds after the start of “System Prelube”.

Normally, they open coincident with the com ple tion of

“Sys tem Coastdown” with the fol low ing ex cep tions:

a. If a “Leaving Chilled Liquid - Low Tem per a ture”

cy cling shutdown occurs, they do not open at the

com ple tion of “System Coastdown”. They remain

closed for the duration of the shutdown or until the

Keypad COMPRESSOR switch is placed in the

Stop-Reset (O) position, whereupon they open.

b. If Microboard Program Switch SW1-8 is in the ON

position, they do not open at the completion of “Sys-

tem Coastdown” when the chiller shuts down on a

“Multiunit Cycling - Contacts Open” or “Sys tem

Cy cling - Contacts Open” cycling shut down. They

re main closed for the duration of the shut down or until

the Keypad COMPRESSOR switch is placed in the

Stop-Reset (O) position, where up on they open.

K1 - Anticipatory Alarm (TB2-55/56)

Dry closure con tacts. Contacts close when one of the

fol low ing Warn ing messages is Displayed. On most

warn ings, the con tacts automatically open when the

warning con di tion is no longer present. On those warn-

ings marked with an as ter isk, the contacts will open only

after the warn ing condition is no longer present and the

WARN ING RESET key is pressed when logged in at

OP ER A TOR ac cess level or higher.

Real Time Clock Failure, Condenser or Evaporator Trans-

duc er Error*, Refrigerant Level Out of Range, Standby

Lube-Low Oil Pressure*, Setpoint Over ride*, Condens-

er-High Pressure limit, Evaporator-Low Pres sure Limit,

Vanes Uncalibrated-Fixed Speed, Har mon ic Filter-Op-

eration In hib it ed, Harmonic Filter-Data Loss, Har mon ic

Filter-Input Fre quen cy Out Of Range. The following only

applies to Flash Memory Card version

C.MLM.01.05.xxx

and lat er – Ex cess Surge Detected*, Surge Detected – Ex cess

Surge Limit.

K2 - Remote Mode Ready to Start (only oper-

ational in Digital, Analog or ISN Remote mode)

(TB2-26/27)

Dry closure status contacts that are closed to indicate to

a Remote device that the chiller will start upon re ceipt

of a remote start signal. The contacts open co in ci dent

with any Cycling or Safety shutdown or anytime the

Keypad COM PRES SOR switch is placed in the Stop -

Reset (O) po si tion. On Cycling shutdowns, the con tacts

will close when the cycling condition clears. On safety

shutdowns, the con tacts will close only after the Safety

condition clears, a manual reset is per formed by plac ing

the COM PRES SOR switch in the Stop-Reset (O) posi-

tion and then back to the RUN (I) position.

K3 - Safety Shutdown Status (TB2-42/43)

Dry clo sure status contacts. They close coincident with

a Safe ty shutdown. They remain closed until the safety

con di tion clears and a manual reset is performed by

placing the COMPRESSOR switch in the Stop-Reset(O)

po si tion, whereupon they open.

K4 - Cycling Shutdown Status (TB2-40/41)

Dry clo sure status contacts. They close coincident with a

Cy cling shutdown. They remain closed until the cy cling

condition clears, whereupon they open.

K5 - Condenser Motor Pump Starter (TB2-150/

151)

(applies to Flash Memory Card version

C.MLM.01.04.xxx and lat er)

Dry closure contacts. Contacts close coincident with be-

gin ning of “SYSTEM RUN”. They open coincident with

the beginning of “SYSTEM COASTDOWN” un less the

chiller is equipped with the Mod “B” Solid State Starter.

Summary of Contents for MAXE OPTIVIEW YK

Page 28: ...YORK INTERNATIONAL 28 FORM 160 54 M1 503 Microboard FIG 7 MICROBOARD LD07776...

Page 60: ...YORK INTERNATIONAL 60 FORM 160 54 M1 503 Keypad FIG 32 KEYPAD CONNECTOR LD04074...

Page 61: ...FORM 160 54 M1 503 61 YORK INTERNATIONAL FIG 33 KEYPAD LD04075 LD04076 8...

Page 173: ...FORM 160 54 M1 503 173 YORK INTERNATIONAL 26 This page intentionally left blank...

Page 177: ...FORM 160 54 M1 503 177 YORK INTERNATIONAL 26 This page intentionally left blank...