FORM 160.54-M1(503)

59

YORK INTERNATIONAL

SECTION 8

KEYPAD

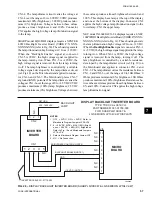

(REFER TO FIGURES 32 & 33)

The

Keypad

contains touch-sensitive keys that allow the

Operator to interface with the OptiView Control Center.

The Operator presses the keys to request the desired

screens of information and enter System Setpoints.

The top layer of the Keypad contains embossed areas

identifying the keys. Under each embossed key area

are two conductors, one on top of the other, separated

by an air space. The conductors are arranged in a ma-

trix of rows and columns and connected to the Key pad

connector as shown in Fig. 32. The em bossed area of

each key is located directly over the in ter sec tion point

of the conductors. Pressing the embossed key area

caus es contact and electrical continuity between the

two conductors. For example, pressing the “1” key

creates con ti nu ity between the Keypad connector pin

5 (col umn 3) and pin 13 (row 4). Since this connector

is in ter faced to the Microboard (J18), the Microboard

sens es this continuity as described below and con cludes

the “1” key is pressed.

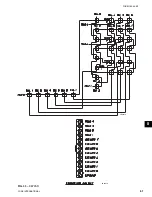

The Microboard Program continuously scans the Key-

pad to determine if a key is pressed. Beginning with

row 1 and proceeding through all rows, the Program

places a “logic low” (<1VDC) on a row, a “logic high”

(>4VDC) on the remaining rows and reads the col umns.

A logic low in any column indicates a key in that col umn

and row is pressed. For example, if at the time row 4

is being driven low, if column 3 is low, then the Micro

con cludes the key at co or di nate of row 4 and column 3

is pressed. Since the co or di nates of all keys are stored

in the Microboard’s Program, it can iden ti fy which key

is at this co or di nate and responds ac cord ing ly. In this

ex am ple the “1” key is pressed.

In order for the Microboard to reliably detect closed and

open keys, each key must meet a closed circuit and open

circuit resistance requirement. When a key is pressed, the

contact resistance must be < 100 Ohms. When a key is

not pressed, the contact resistance must be > 1Meg Ohm.

If the Microboard is not responding to a pressed key, or

if it’s detecting a closed key when none are pressed, it

could be be cause the contact re sis tance requirements are

not being met. The operation of each key can be checked

with an Ohmmeter. To check the open and closed con-

tact resistance of any key, re fer to the “Di ag nos tics and

Troubleshooting” Section 23 of this book.

The Keypad is attached to the front of the OptiView

Control Cen ter door with an adhesive backing. If ser vice

re place ment is required, start at one corner and slowly

peel the Keypad from the door. The rear side of the re-

place ment Keypad is coated with an adhesive covered

with a paper backing. Remove the paper back ing, align

the Display and rocker switch openings and apply the

Key pad to the door.

8

Summary of Contents for MAXE OPTIVIEW YK

Page 28: ...YORK INTERNATIONAL 28 FORM 160 54 M1 503 Microboard FIG 7 MICROBOARD LD07776...

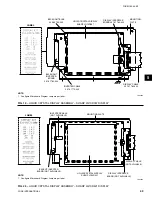

Page 60: ...YORK INTERNATIONAL 60 FORM 160 54 M1 503 Keypad FIG 32 KEYPAD CONNECTOR LD04074...

Page 61: ...FORM 160 54 M1 503 61 YORK INTERNATIONAL FIG 33 KEYPAD LD04075 LD04076 8...

Page 173: ...FORM 160 54 M1 503 173 YORK INTERNATIONAL 26 This page intentionally left blank...

Page 177: ...FORM 160 54 M1 503 177 YORK INTERNATIONAL 26 This page intentionally left blank...