FORM 160.54-M1(503)

95

YORK INTERNATIONAL

SECTION 15

OIL PUMP VARIABLE SPEED DRIVE

(REFER TO FIG. 53 - 55)

On style D and later chillers, the oil pump is driven

by a

Variable Speed Drive (VSD)

(Refer to Service

Man u al 160.52-M2 for details of this device). In nor mal

op er a tion, the oil pump speed is au to mat i cal ly con trolled

to main tain a desired oil pres sure. The speed can be

man u al ly con trolled with the Keypad keys using the Oil

Sump Screen with Ser vice access level.

On those chillers equipped with the oil pump VSD, the

VSD operation as described below must be

EN ABLED

by placing Microboard Program Switch SW1-2 in the

ON position. Those chillers not equipped with the oil

pump VSD must have this operation

DISABLED

by

plac ing SW1-2 in the OFF position. Refer to Table 2,

“Microboard Program Switches”.

The programming of the Setpoints referred to below is

performed on the Oil Sump Screen using instructions

in the “System Calibration, Service Setpoints and Re set

Procedures” section of this book. These Setpoints should

not be programmed by anyone other than a qual i

fi

ed Ser-

vice Technician. Variable speed oil pump chill ers are not

equipped with the Liquid Line Solenoid Valve (2SOL),

or High Speed Thrust So le noid Valve (4SOL). There-

fore, when Oil Pump VSD operation is

ENABLED

with

Program Switch SW1-2, the Program is con

fi

g ured to

operate the chiller without these so le noid valves. Op-

er a tion Sequence Timing Diagrams in Fig. 4 and 5 depict

chiller operation with the Oil Pump VSD enabled or

disabled. Also, when equipped with the oil pump VSD,

the Microboard, under Program con trol, controls the Oil

Heater to maintain a speci

fi

c oil temperature as de scribed

in the “Oil Heater” sec tion below.

AUTOMATIC OPERATION

Under Program control, a speed command signal from

the Microboard controls the oil pump speed by vary ing

the VSD output frequency. The speed command is in

the form of a Pulse Width Modulation (PWM) Sig nal

as explained below. During the

System Prelube

period

and the

fi

rst 15 seconds of

System Run

, the Pro gram

operates the oil pump VSD over the range of 25 Hz to 60

Hz to maintain the oil pressure to the target value of 45

PSID. For the remainder of

System Run

and the

Coast-

down

period, it operates it over the same fre quen cy

range to maintain the pressure to the pro grammed

Oil

Pressure Setpoint.

When the chiller is started, 13 seconds after the

Sys tem

Prelube

is initiated, the Microboard (J20-3) starts the oil

pump by driving the EN (enable) input of the Oil Pump

VSD to a Logic Low level (<1VDC). The Microboard

(J20-1) then applies a speed command sig nal to the

PWM input of the VSD that ramps the VSD output fre-

quen cy from 25 Hz (45 Hz on all “P” com pres sors. 45 Hz

on other compressor applications equipped with Flash

Memory Card version C.MLM.01.05.xxx and later) to

what ev er fre quen cy is re quired (up to a max i mum of 60

Hz) to achieve the

Target Oil Pressure

. (If equipped

with Flash Memory card version C.MLM.01.08.xxx

(and later), it is held at 45Hz for 8 seconds before re-

leasing to normal control).

The Tar get Oil Pres sure is

fi

xed at 45 PSID. The speed com mand is dis played on

the Oil Sump Screen as

OIL PUMP DRIVE COM-

MAND FRE QUEN CY = XX HZ

. The speed command

to the VSD is mod u lat ed as re quired to main tain the 45

PSID Target Oil Pressure for the re main der of

System

Prelube

and the

fi

rst 15 sec onds of

Sys tem Run

. While

this target is in effect, it is dis played on the Oil Sump

Screen as

TARGET OIL PRES SURE = 45 PSID

. The

time re main ing that the Target Oil Pres sure is in effect is

displayed as a count down timer in the message

PULL-

DOWN TIME RE MAIN ING = XX SEC

. After the

com pres sor has been run ning for 15 seconds, the speed

of the VSD is con trolled to main tain the pro grammed

Oil

Pres sure Setpoint

(20 to 45 PSID). This is dis played on

the Oil Sump Screen as

SETPOINT OIL PRES SURE

= XX PSID

.

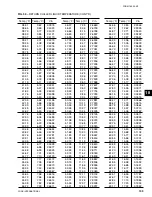

During Oil Pump operation, the following minimum and

maximum oil pressures are allowed:

1. During

Automatic

operation, if either of the fol-

lowing conditions occur, a Safety shutdown is per-

formed and

OIL - VARIABLE SPEED PUMP

- PRESSURE SETPOINT NOT ACHIEVED

is dis played. These conditions are not checked in

MANUAL

operation.

a. If the Oil Pressure is <35 PSID (25 PSID on

“P” compressors) for 5 continuous seconds

during the last 10 seconds of

System Prelube

or dur ing the

fi

rst 15 seconds of

System Run

.

b. If the Oil Pressure is < the programmed Oil

Pressure Setpoint and the speed command is

at 60 Hz for 5 continuous seconds, any

time after the

fi

rst 30 seconds of SYSTEM

RUN.

15

Summary of Contents for MAXE OPTIVIEW YK

Page 28: ...YORK INTERNATIONAL 28 FORM 160 54 M1 503 Microboard FIG 7 MICROBOARD LD07776...

Page 60: ...YORK INTERNATIONAL 60 FORM 160 54 M1 503 Keypad FIG 32 KEYPAD CONNECTOR LD04074...

Page 61: ...FORM 160 54 M1 503 61 YORK INTERNATIONAL FIG 33 KEYPAD LD04075 LD04076 8...

Page 173: ...FORM 160 54 M1 503 173 YORK INTERNATIONAL 26 This page intentionally left blank...

Page 177: ...FORM 160 54 M1 503 177 YORK INTERNATIONAL 26 This page intentionally left blank...