68

YORK INTERNATIONAL

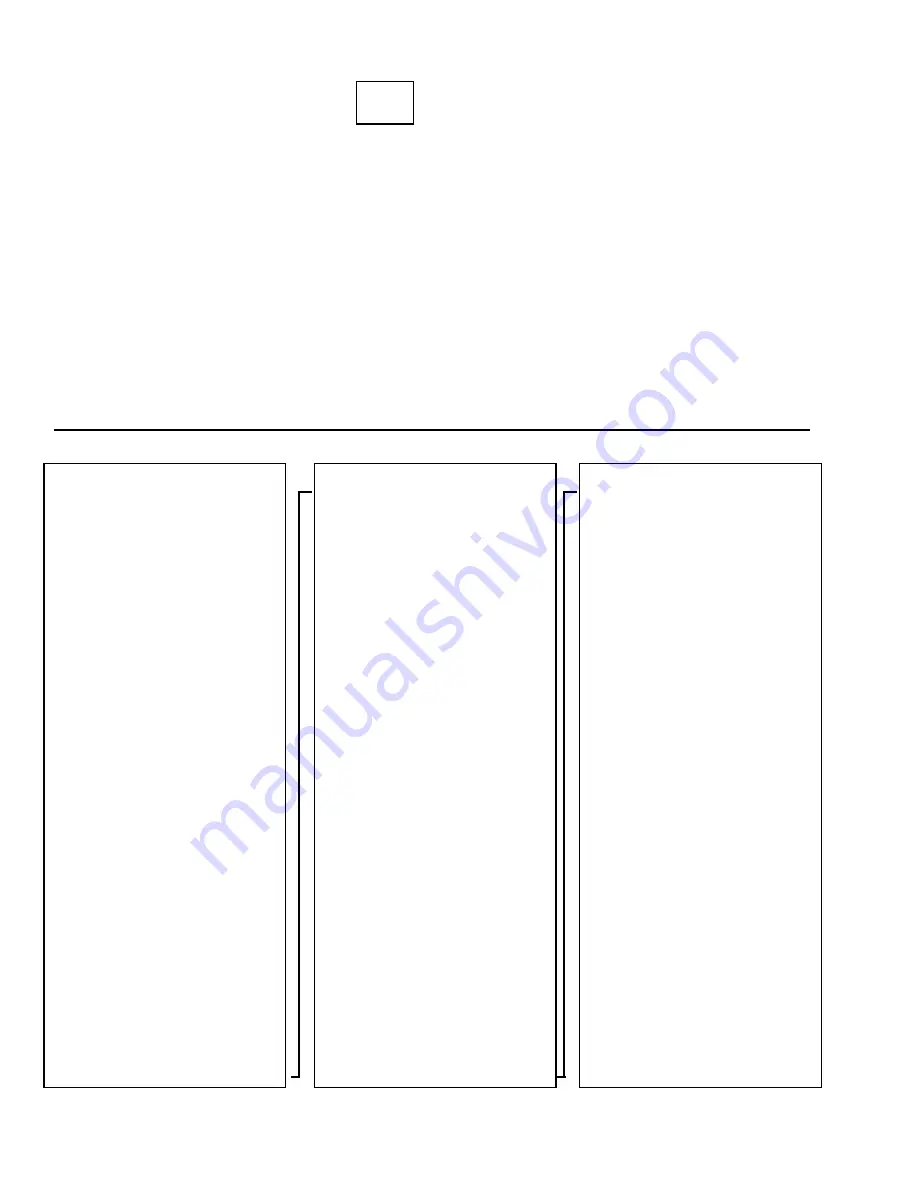

FIG. 22 – HISTORY PRINTOUT

NOTE: In actual print-outs, this would be one continuous print-out.

YORK INTERNATIONAL CORPORATION

RECIPROCATING WATER CHILLERS

SAFETY SHUTDOWN NUMBER 1

SHUTDOWN @ 8:48AM 6/3/98

SYS 1 STATUS:

NO FAULTS

SYS 2

MOTOR CURRENT SHUTDOWN

RETURN WATER TEMP

65.0 DEGF

LEAVING WATER TEMP

54.0 DEGF

LOW WATER CUTOUT

36.0 DEGF

SETPOINT TEMP

45.0 DEGF

OUTSIDE AIR TEMP

75.0 DEGF

LOW AMBIENT CUTOUT

10.0 DEGF

LOW PRESSURE CUTOUT

44 PSIG

LEAD SYSTEM

SYS 1

CONTROL TYPE

LCHWT

COOLING RANGE

45.0 TO 47.0 DEGF

SYSTEM 1 DATA

COMPRESSOR STATUS

ON

MOTOR AMPS

50 %FLA

SUCTION PRESSURE

61 PSIG

DISCHARGE PRESSURE

143 PSIG

OIL PRESSURE

75 PSID

LIQUID LINE SOLENOID

OFF

RUN PERMISSIVE

ON

STAGES OF LOADING

1

FORWARD FANS

2

REVERSE FANS

OFF

HOT GAS BYPASS VALVE

OFF

SYSTEM 2 DATA

COMPRESSOR STATUS

ON

MOTOR AMPS

0 %FLA

SUCTION PRESSURE

61 PSIG

DISCHARGE PRESSURE

80 PSIG

OIL PRESSURE

1 PSID

LIQUID LINE SOLENOID

OFF

RUN PERMISSIVE

ON

STAGES OF LOADING

1

FORWARD FANS

1

REVERSE FANS

OFF

HOT GAS BYPASS VALVE

OFF

YORK INTERNATIONAL CORPORATION

RECIPROCATING WATER CHILLERS

SAFETY SHUTDOWN NUMBER 2

SHUTDOWN @ 8:47AM 6/3/98

SYS 1 STATUS:

NO FAULTS

SYS 2

MOTOR CURRENT SHUTDOWN

RETURN WATER TEMP

65.0 DEGF

LEAVING WATER TEMP

54.0 DEGF

LOW WATER CUTOUT

36.0 DEGF

SETPOINT TEMP

45.0 DEGF

OUTSIDE AIR TEMP

75.0 DEGF

LOW AMBIENT CUTOUT

10.0 DEGF

LOW PRESSURE CUTOUT

44 PSIG

LEAD SYSTEM

SYS 1

CONTROL TYPE

LCHWT

COOLING RANGE

45.0 TO 47.0 DEGF

SYSTEM 1 DATA

COMPRESSOR STATUS

ON

MOTOR AMPS

50 %FLA

SUCTION PRESSURE

61 PSIG

DISCHARGE PRESSURE

143 PSIG

OIL PRESSURE

75 PSID

LIQUID LINE SOLENOID

ON

RUN PERMISSIVE

ON

STAGES OF LOADING

1

FORWARD FANS

2

REVERSE FANS

OFF

HOT GAS BYPASS VALVE

OFF

SYSTEM 2 DATA

COMPRESSOR STATUS

ON

MOTOR AMPS

0 %FLA

SUCTION PRESSURE

61 PSIG

DISCHARGE PRESSURE

80 PSIG

OIL PRESSURE

1 PSID

LIQUID LINE SOLENOID

OFF

RUN PERMISSIVE

ON

STAGES OF LOADING

1

FORWARD FANS

1

REVERSE FANS

OFF

HOT GAS BYPASS VALVE

OFF

YORK INTERNATIONAL CORPORATION

RECIPROCATING WATER CHILLERS

SAFETY SHUTDOWN NUMBER 3

SHUTDOWN @ 8:47AM 6/3/98

SYS 1 STATUS:

NO FAULTS

SYS 2

MOTOR CURRENT SHUTDOWN

RETURN WATER TEMP

65.0 DEGF

LEAVING WATER TEMP

54.0 DEGF

LOW WATER CUTOUT

36.0 DEGF

SETPOINT TEMP

45.0 DEGF

OUTSIDE AIR TEMP

75.0 DEGF

LOW AMBIENT CUTOUT

10.0 DEGF

LOW PRESSURE CUTOUT

44 PSIG

LEAD SYSTEM

SYS 1

CONTROL TYPE

LCHWT

COOLING RANGE

45.0 TO 47.0 DEGF

SYSTEM 1 DATA

COMPRESSOR STATUS

ON

MOTOR AMPS

50 %FLA

SUCTION PRESSURE

61 PSIG

DISCHARGE PRESSURE

143 PSIG

OIL PRESSURE

75 PSID

LIQUID LINE SOLENOID

ON

RUN PERMISSIVE

ON

STAGES OF LOADING

1

FORWARD FANS

2

REVERSE FANS

OFF

HOT GAS BYPASS VALVE

OFF

SYSTEM 2 DATA

COMPRESSOR STATUS

ON

MOTOR AMPS

0 %FLA

SUCTION PRESSURE

61 PSIG

DISCHARGE PRESSURE

80 PSIG

OIL PRESSURE

1 PSID

LIQUID LINE SOLENOID

OFF

RUN PERMISSIVE

ON

STAGES OF LOADING

1

FORWARD FANS

1

REVERSE FANS

OFF

HOT GAS BYPASS VALVE

OFF

_

_

History

The HISTORY key allows the operator to remotely ob-

tain a printout of information relating to the last 3 Safety

Shutdowns which occurred. The information is stored at

the instant of the fault regardless of whether the fault

caused a lockout to occur. The information is also not

affected by power failures (long term internal memory

battery backup is built into the circuit board) or manual

resetting of a fault lockout.

When the HISTORY key is pressed, a Printout is trans-

mitted of all system Operating conditions which were

stored at the “instant the fault occurred” for each of the 3

SAFETY SHUTDOWN BUFFERS. There is one buffer

HISTORY

(storage area) for data related to each of the last 3 safety

shutdowns.

The printout will begin with the most recent fault which

occurred. The most recent fault will always be stored as

SAFETY SHUTDOWN NO. 1 (See printout Fig. 22). Iden-

tically formatted fault information will then be printed for

SAFETY SHUTDOWN NO. 2 and SAFETY SHUTDOWN

NO. 3.

Information contained in the SAFETY SHUTDOWN Buff-

ers is very important when attempting to troubleshoot a

system problem. This data reflects the system condi-

tions at the instant the fault occurred and often reveals

other system conditions which actually caused the safety

threshold to be exceeded. (See Fig. 22)

Summary of Contents for Millennium YCAJ150

Page 21: ...FORM 150 65 NM4 21 YORK INTERNATIONAL LD02461 FIG 6 ELEMENTARY DIAGRAM Cont d...

Page 22: ...22 YORK INTERNATIONAL ELEMENTARY DIAGRAM...

Page 24: ...24 YORK INTERNATIONAL CONNECTION DIAGRAM FIG 7 CONNECTION DIAGRAM LD02463...

Page 25: ...FORM 150 65 NM4 25 YORK INTERNATIONAL FIG 7 CONNECTION DIAGRAM Cont d LD02462...

Page 30: ...30 YORK INTERNATIONAL FIG 8 SYSTEM WIRING Cont d LD02499...

Page 100: ...100 YORK INTERNATIONAL LD02654 FIG 37B LOUVER BRACKETS INSTALLATION...

Page 103: ...FORM 150 65 NM4 103 YORK INTERNATIONAL LD02656 FIG 39A LOUVER INSTALLATION SIDES...

Page 104: ...104 YORK INTERNATIONAL LD02654 FIG 39B LOUVER BRACKETS INSTALLATION...

Page 108: ...108 YORK INTERNATIONAL FIG 40B CONDENSER COIL LOUVER INSTALLATION FRONT AND BACK LD02659...

Page 110: ...110 YORK INTERNATIONAL FIG 41 REMOTE RESET BOARD LD02666 P1...