FORM 201.18-MN4

FORM 201.18-NM4

YORK INTERNATIONAL

YORK INTERNATIONAL

67

67A

FIG. 26 – CONNECTION DIAGRAM

FIG. 44 & 45 LEGEND (PAGES 90 & 91)

LD03281

FIG. 27 – CONNECTION DIAGRAM (CONT’D)

LD04181

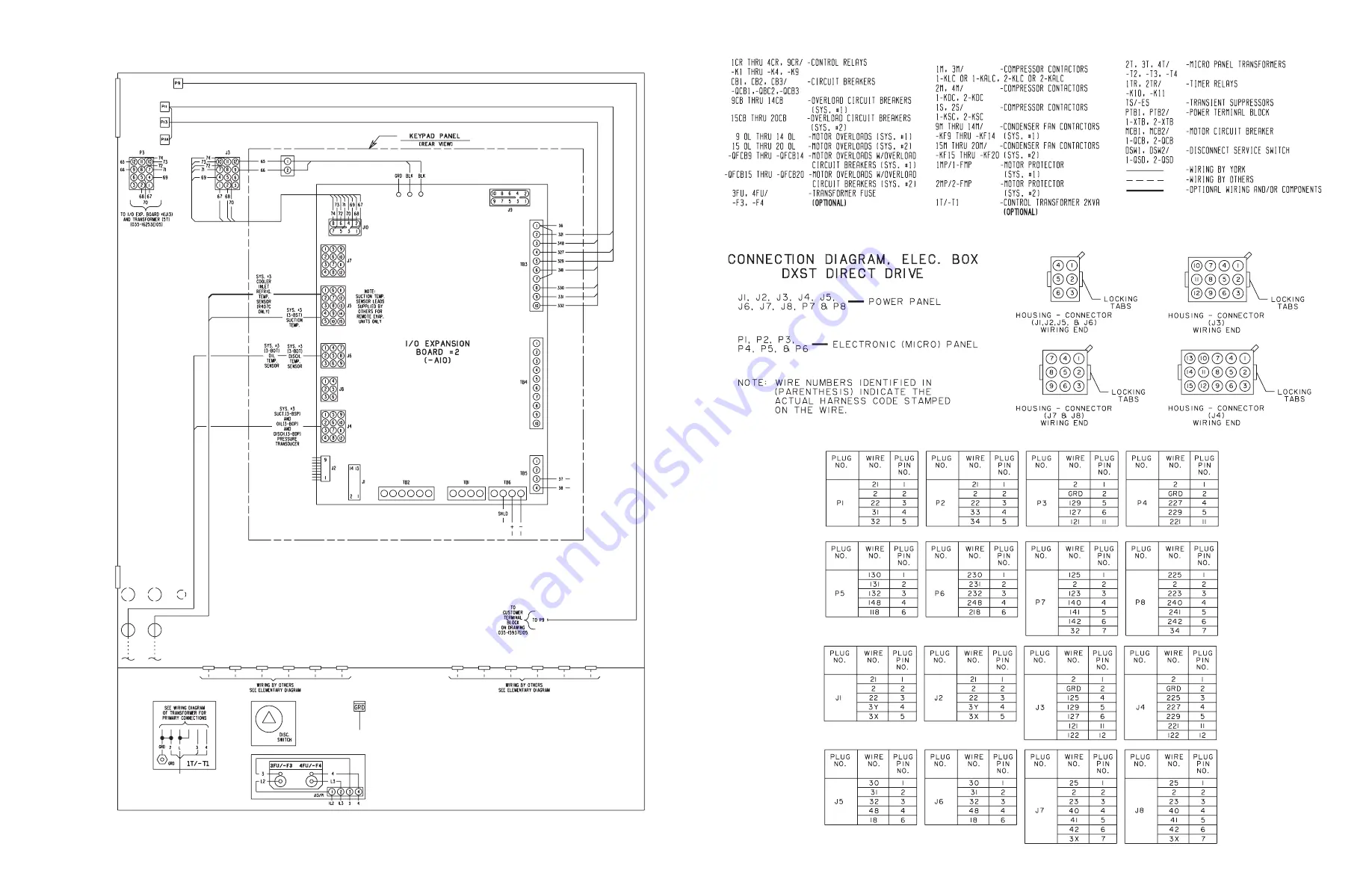

CONNECTION DIAGRAM ELECTRIC BOX DXST DIRECT DRIVE

CONNECTION DIAGRAM

Box Information continued from page 66

Summary of Contents for Millennium YCAS 0693

Page 49: ...49 YORK INTERNATIONAL FORM 201 18 NM4 7 This page intentionally left blank...

Page 65: ...65 YORK INTERNATIONAL FORM 201 18 NM4 LD04179 7...

Page 79: ...79 YORK INTERNATIONAL FORM 201 18 NM4 This page intentionally left blank 7...

Page 83: ...83 YORK INTERNATIONAL FORM 201 18 NM4 This page intentionally left blank 7...

Page 87: ...87 YORK INTERNATIONAL FORM 201 18 NM4 LD04268 7...