FORM 201.10-NM1

79

YORK INTERNATIONAL

Operating Hours

Start Counter

Accumulated running hours and starts on each

compressor is displayed. The hours counter for an

individual system count to a total of 99,999 hours before

rollover. A total of 99,999 starts can be logged on a

system before the start counter will rollover.

The numbers “1” and “2” on the display indicate

compressor #1 and compressor #2.

These counters are zeroed at the factory, but may

indicate run time and number of starts logged during

factory testing prior to shipment.

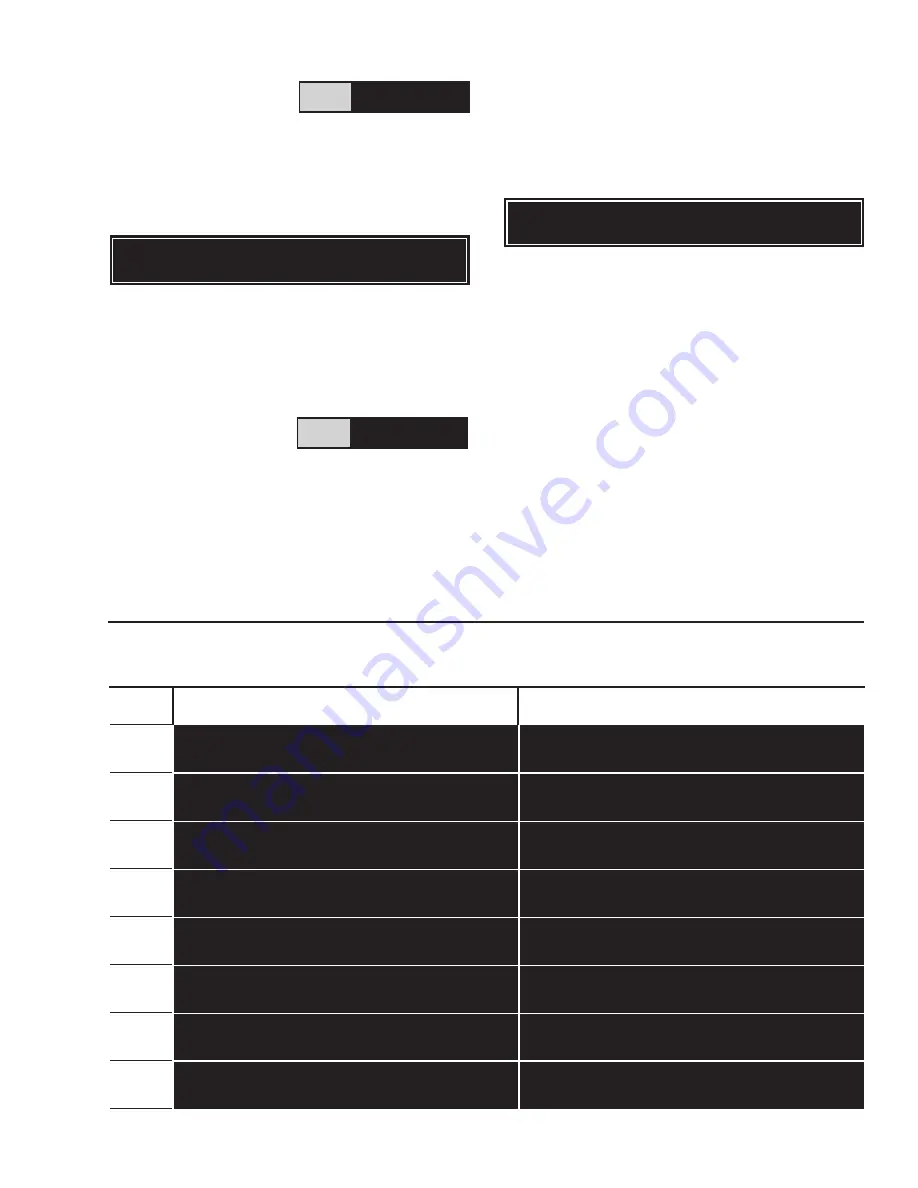

Options

The OPTIONS key provides a display of options which

have been selected by the user. These options are

selected by the S1 Dip Switch on the Microprocessor

Board (Fig. 22). Proper programming of the switch is

important during the commissioning of the chiller. The

OPTIONS display allows a means of verifying the Dip

Switch positions without looking at or handling the

Microprocessor Board. It also eliminates visual

inspection of the sometimes difficult to determine Dip

Switch position.

When the OPTIONS key is pressed, the following

message will first be displayed for 3 seconds:

Eight (8) Option Messages will then follow. Each will be

displayed for 3 seconds before the next display is

automatically indexed. When all messages are

displayed, the display message will automatically change

to show a chiller STATUS message, just as if the

STATUS key was pressed.

Refer to Table 1 for a list of the displays and the

corresponding switch positions in the order they appear.

Two possible messages may appear for each of the eight

messages depending on the Dip Switch position.

A detailed explanation of the meaning of each message

and a guide to programming the associated switch is

provided on page 80.

Fig. 22 shows the location and verification of switch

positioning of S1.

OPERATING HRS.

START COUNTER

H R S

1 =

1 4 3 , 2

=

3 8 2

S T R

1 =

1 1 7 , 2

=

1 1 2

OPTIONS

T H E

F O L L O W I N G

A R E

P R O G R A M M E D

DISPLAY/

SWITCH “OPEN” MESSAGE

SWITCH “CLOSED” MESSAGE

SWITCH

1

2

3

4

5

6

7

8

R E F R I G E R A N T

T Y P E

R 1 3 4 A

R E F R I G E R A N T

T Y P E

R 2 2

M A N U A L

L E A D

/

L A G

A U T O M A T I C

L E A D

/

L A G

A C R O S S - T H E - L I N E

M O T O R

S T A R T I N G

W Y E

D E L T A

M O T O R

S T A R T I N G

E N G L I S H

U N I T S

R E A D O U T

S I

U N I T S

R E A D O U T

T H E R M A L

E X P A N S I O N

V A L V E S

T H E R M A L

E X P A N S I O N

V A L V E S

L O C A L

C O N T R O L

M O D E

R E M O T E

C O N T R O L

M O D E

S T A N D A R D

A M B I E N T

L O W

A M B I E N T

C O N T R O L

W A T E R

C O O L I N G

B R I N E

C O O L I N G

TABLE 1 – SWITCH POSITION AND DISPLAY

Summary of Contents for Millennium YCAS 216X

Page 11: ...FORM 201 10 NM1 11 YORK INTERNATIONAL YCAS 140 246 DIMENSIONS English LD01444 LD01446...

Page 13: ...FORM 201 10 NM1 13 YORK INTERNATIONAL YCAS 140 246 DIMENSIONS SI LD01440 LD01442...

Page 15: ...FORM 201 10 NM1 15 YORK INTERNATIONAL YCAS 216X 266X DIMENSIONS English LD01454 LD01454...

Page 17: ...FORM 201 10 NM1 17 YORK INTERNATIONAL YCAS 216X 266X DIMENSIONS SI LD01450 LD01448...

Page 33: ...FORM 201 10 NM1 33 YORK INTERNATIONAL 28514A FILTER DRYER LIQUID STOP VALVE...

Page 37: ...FORM 201 10 NM1 37 YORK INTERNATIONAL LD01285 FIG 3 SCREW CHILLER REFIGERANT FLOW DIAGRAM...

Page 59: ...FORM 201 10 NM1 59 YORK INTERNATIONAL FIG 11 CONTINUED LD01465 D...

Page 61: ...FORM 201 10 NM1 61 YORK INTERNATIONAL FIG 12 CONTINUED LD01458 D...

Page 69: ...FORM 201 10 NM1 69 YORK INTERNATIONAL FIG 16 CONTINUED LD01206 D...

Page 71: ...FORM 201 10 NM1 71 YORK INTERNATIONAL FIG 17 CONTINUED LD01202 D...