29

YORK INTERNATIONAL

FORM 201.18-NM3

INSTALLATION

LOCATION REQUIREMENTS

To achieve optimum performance and trouble-free ser-

vice, it is essential that the proposed installation site

meets with the location and space requirements for the

model being installed. For dimensions, weight and

space requirements, including service access details,

refer to the Technical Data Section.

It is important to ensure that the minimum service ac-

cess space is maintained for cleaning and maintenance

purposes.

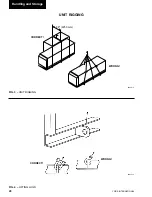

OUTDOOR INSTALLATIONS

The units can be installed at ground level, or on a

suitable rooftop location. In both cases an adequate

supply of air is required. Avoid locations where the

sound output and air discharge from the unit may be

objectionable.

The location should be selected for minimum sun ex-

posure and away from boiler flues and other sources of

airborne chemicals that could attack the condenser coils

and steel parts of the unit.

If located in an area which is accessible to unautho-

rized persons, steps must be taken to prevent access to

the unit by means of a protective fence. This will help

to prevent the possibility of vandalism, accidental dam-

age, or possible harm caused by unauthorized removal

of protective guards or opening panels to expose rotat-

ing or high voltage components.

For ground level locations, the unit must be installed

on a suitable flat and level concrete base that extends

to fully support the two side channels of the unit base

frame. A one-piece concrete slab, with footings extend-

ing below the frost line is recommended. To avoid noise

and vibration transmission the unit should not be se-

cured to the building foundation.

On rooftop locations, choose a place with adequate

structural strength to safely support the entire operat-

ing weight of the unit and service personnel. The unit

can be mounted on a concrete slab, similar to ground

floor locations, or on steel channels of suitable strength.

The channels should be spaced at the same centres as

the vibration mounting holes in the unit base frame and

must be at least 4-3/4" (120 mm) wide at the contact

points. This will allow vibration isolators to be fitted if

required.

Any ductwork or attenuators fitted to the unit must not

have a total static pressure resistance, at full unit air-

flow, exceeding the capability of the fans installed in

the unit.

INDOOR INSTALLATIONS

The unit can be installed in an enclosed plant room

providing the floor is level and of suitable strength to

support the full operating weight of the unit. It is es-

sential that there is adequate clearance for airflow to

the unit. The discharge air from the top of the unit must

be ducted away to prevent recirculation of air within

the plant room. If common ducts are used for fans, non-

return dampers must be fitted to the outlet from each

fan.

The discharge ducting must be properly sized with a

total static pressure loss, together with any intake static

pressure loss, less than the available static pressure ca-

pability for the type of fan fitted.

The discharge air duct usually rejects outside the build-

ing through a louver. The outlet must be positioned to

prevent the air being drawn directly back into the air

intake for the condenser coils, as such recirculation will

affect unit performance.

LOCATION CLEARANCES

Adequate clearances around the unit(s) are required for

the unrestricted airflow for the air-cooled condenser

coils and to prevent recirculation of warm discharge

air back onto the coils. If clearances given are not main-

tained, airflow restriction or recirculation will cause a

loss of unit performance, an increase in power con-

sumption and may cause the unit to malfunction. Con-

sideration should also be given to the possibility of

down drafts, caused by adjacent buildings, which may

cause recirculation or uneven unit airflow.

For locations where significant cross winds are ex-

pected, such as exposed roof tops, an enclosure of solid

or louver type is recommended to prevent wind turbu-

lence interfering with the unit airflow.

4

Summary of Contents for MILLENNIUM YCAS 250

Page 61: ...61 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank 7...

Page 65: ...65 YORK INTERNATIONAL FORM 201 18 NM3 LD04179 7...

Page 79: ...79 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank 7...

Page 83: ...83 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank 7...

Page 87: ...87 YORK INTERNATIONAL FORM 201 18 NM3 LD04268 7...

Page 195: ...195 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank...