42

YORK INTERNATIONAL

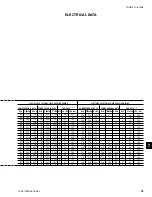

Check that the tapping used conforms to the site supply

voltage.

Switch Settings

Ensure that the unit Auto/OFF switch on the display

door and the micro board system switches S2 and S5

are set to “0” (OFF). Set the red handled emergency

stop device on the options panel to “1” (ON). For units

fitted with door interlocked circuit breakers the power

panel doors must be closed and the devices set to “1”

(ON). The customer’s disconnection devices can now

be set to ON.

The machine is now live!

The unit is fitted with an under voltage relay in each

panel and it may take between 5 to 10 seconds for its

contacts to close and energize the unit’s electronics, in-

cluding the display on the main panel.

Crankcase Heaters

Verify the compressor crankcase heaters are energized.

If the ambient temperature is above 96°F (36°C) the

compressor crankcase heaters must be on for at least

24 hours before start-up to ensure all refrigerant liquid

is driven out of the oil. If the ambient temperature is

below 86°F (30°C) then allow 8 hours.

Water System

Verify that the chilled liquid system has been installed

correctly, and has been commissioned with the correct

direction of water flow through the cooler. The inlet

should be at the refrigerant pipework connection end of

the cooler. Purge air from the top of the cooler using the

plugged air vent mounted on the top of the cooler body.

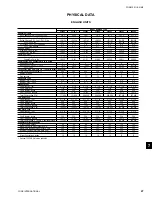

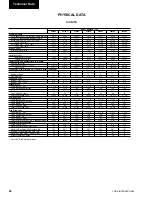

Flow rates and pressure drops must be within the limits

given in the Technical Data Section. Operation outside

of these limits is undesirable and could cause damage.

Flow Switch

Verify a chilled water flow switch is correctly fitted in

the customer’s pipework on the cooler outlet, and wired

into the control panel correctly using shielded cable.

There should be a straight run of at least 5 pipe diam-

eters on either side of the flow switch. The flow switch

should be connected to terminals 13 and 14 in the

micropanel ( Figs. 11 and 12, pages 39 and 40).

Temperature sensor(s)

Ensure the leaving liquid temperature sensor is coated

with heat conductive compound (part no. 013-00890-

000) and is inserted in the water outlet sensor pocket of

the cooler. This sensor also acts as the freeze protec-

tion thermostat sensor and must always be in the water

OUTLET sensor pocket.

Control Supply

Verify the control panel display is illuminated.

Programmed Options

Verify that the options factory programmed into the Mi-

crocomputer Control Center are in accordance with the

customer’s order requirements by pressing the ‘Options’

key on the keypad and reading the settings from the

display.

Programmed Settings

Ensure the system cut-out and operational settings are

in accordance with the instructions provided in Sec-

tion 8 (page176) and with the general chiller opera-

tional requirements by pressing the ‘Program’ key. The

chilled liquid temperature control settings need to be

set according to the unit model and required operat-

ing conditions.

Date and Time

Program the date and time by first ensuring that the

CLK jumper J18 on the microprocessor board is in the

ON position (top two pins). Then press the ‘Clock Set

Time’ key and set the date and time. (See Section 7.)

Start/Stop Schedule

Program the daily and holiday start/stop by pressing

the ‘Set Schedule/Holiday’ key. (See Section 7.)

Setpoint and Remote Offset

Set the required leaving chilled liquid temperature

setpoint and control range. If remote temperature reset

(offset) is to be used, the maximum reset must be pro-

grammed by pressing the ‘Remote Reset Temp’ key.

(See Section 6.)

Commissioning

Summary of Contents for MILLENNIUM YCAS 250

Page 61: ...61 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank 7...

Page 65: ...65 YORK INTERNATIONAL FORM 201 18 NM3 LD04179 7...

Page 79: ...79 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank 7...

Page 83: ...83 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank 7...

Page 87: ...87 YORK INTERNATIONAL FORM 201 18 NM3 LD04268 7...

Page 195: ...195 YORK INTERNATIONAL FORM 201 18 NM3 This page intentionally left blank...