2

YORK INTERNATIONAL

USING THIS BOOK

The “Theory of Operation” section provides an overview

of the unit control provided by the MILLENNIUM CON-

TROL CENTER. Unit control is described and operating

and status messages that are displayed on the Control

Center display are highlighted.

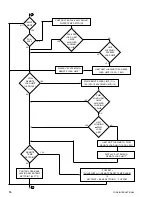

The “Operation Flow Chart” can be used as a quick

reference of unit control providing safety, cycling and

warning messages and the inputs or thresholds that

produce these shutdowns and messages. Also, the

sequence of events of all safety and cycling shutdowns

and respective reset thresholds are detailed in sepa-

rate flow charts. To use this flow chart, start at the

beginning and read down. The starting sequence is

described, followed by the system parameters that are

monitored (checked) by the Control Center. The Con-

trol Center’s response to each of these checks is de-

scribed adjacent to the check. The Control Center is

programmed to respond in a certain way to each of the

monitored parameters. Pressures and temperatures

that exceed safety thresholds result in a safety shut-

down. Other Control Center inputs that are open or

closed cause safety or cycling shutdowns. If a shut-

down is initiated, the displayed message is shown. The

user is directed to a safety or cycling shutdown flow-

chart that details the sequence of events of the shut-

down and allowable restart thresholds. That flowchart

then returns the user to the main flowchart. Not all

responses cause shutdowns. Some cause the Control

Center to limit operation by shutting down a pump or

inhibit unit loading. These responses are shown adja-

cent to the check along with any warning message.

The “Control Center” and “Operation” section describes

how to operate the Control Center. The functions of the

major grouping of keys are described. It also describes

how to display system parameters such as tempera-

tures and pressures. Finally, each system setpoint is

explained along with how to display the programmed

system setpoints.

In the “Programming the Millennium Control Center” sec-

tion, the operator is instructed in how to program sys-

tem setpoints.

The “Service Keys” section describes the function and

operation of the service keys. The service keys are pro-

vided for use by the service technician or operator to

have manual control of certain unit functions.

The “Operating Modes” section describes the various

operating modes and how to change the operating

modes. The “Unit Switch” section describes how to start

and stop the unit.

The “Display Messages” section is a listing of all the

operating, status, safety and cycling shutdown mes-

sages that are displayed on the keypad display. The

meaning of each message is described in detail; in-

cluding the system event threshold that caused the

message to be displayed and the event or threshold

that causes the message to be cleared.

THEORY OF OPERATION

OVERVIEW

An understanding of the operation of a single-stage

absorption chiller requires a review of the chiller’s mi-

cro panel wiring diagram, power panel wiring diagram,

the keypad, and the description which follows. Major

system components include the solution pump (re-

placed by two pumps – absorber and generator on 50

Hz Models YIA-10E3 – YIA-14F3 units equipped with

Franklin pumps – that are individually controlled); refrig-

erant pump; purge (vacuum) pump and purge solenoid

valve; manual purge valve; steam or hot water control

valve feedback potentiometer and steam or hot water

stop valve; generator shell pressure transducer, strong

solution temperature sensor, high pressure and high tem-

perature cut-out switches; steam supply pressure trans-

ducer (steam units only); steam or hot water supply tem-

perature sensor; automatic decrystallization (ADC)

temperature sensor; refrigerant temperature-sensor;

refrigerant temperature leaving the condenser sensor;

low refrigerant temperature cut-out switch; refrigerant

level float switch (1F); motor coolant level float switch

(2F) (units equipped with Franklin pumps only); refriger-

ant level float switch (3F) (units equipped with Buffalo

pumps only); chilled and condenser water flow switches

(condenser water flow switch furnished by others); chilled

and condenser water pumps (by others); inlet and outlet

temperature sensors for chilled and condenser water cir-

cuits; refrigerant (unloader) solenoid valve; stabilizer re-

frigerant solenoid valve; motor coolant solenoid valve

(units equipped with Franklin pumps only); and steam

condensate drain solenoid valve.

An absorption chiller functions by heating a lithium bro-

mide solution to generate hot refrigerant vapor and

strong solution (64.5% lithium bromide).

Summary of Contents for MILLENNIUM YIA-HW-14F3

Page 116: ...YORK INTERNATIONAL 115 FORM 155 16 O3 NOTES...

Page 117: ...116 YORK INTERNATIONAL NOTES...