FORM 155.21-O1 (615)

17

JOHNSON CONTROLS

2

• Purge trending

• Post purge "Oil Clean-up"

The logic to control the YIA auto-purge is ONLY avail

-

able on units equipped with an OptiView Control Panel.

Therefore there can be NO retrofitting of an auto-purge

system on older units unless it is equipped with an

OptiView Control Panel.

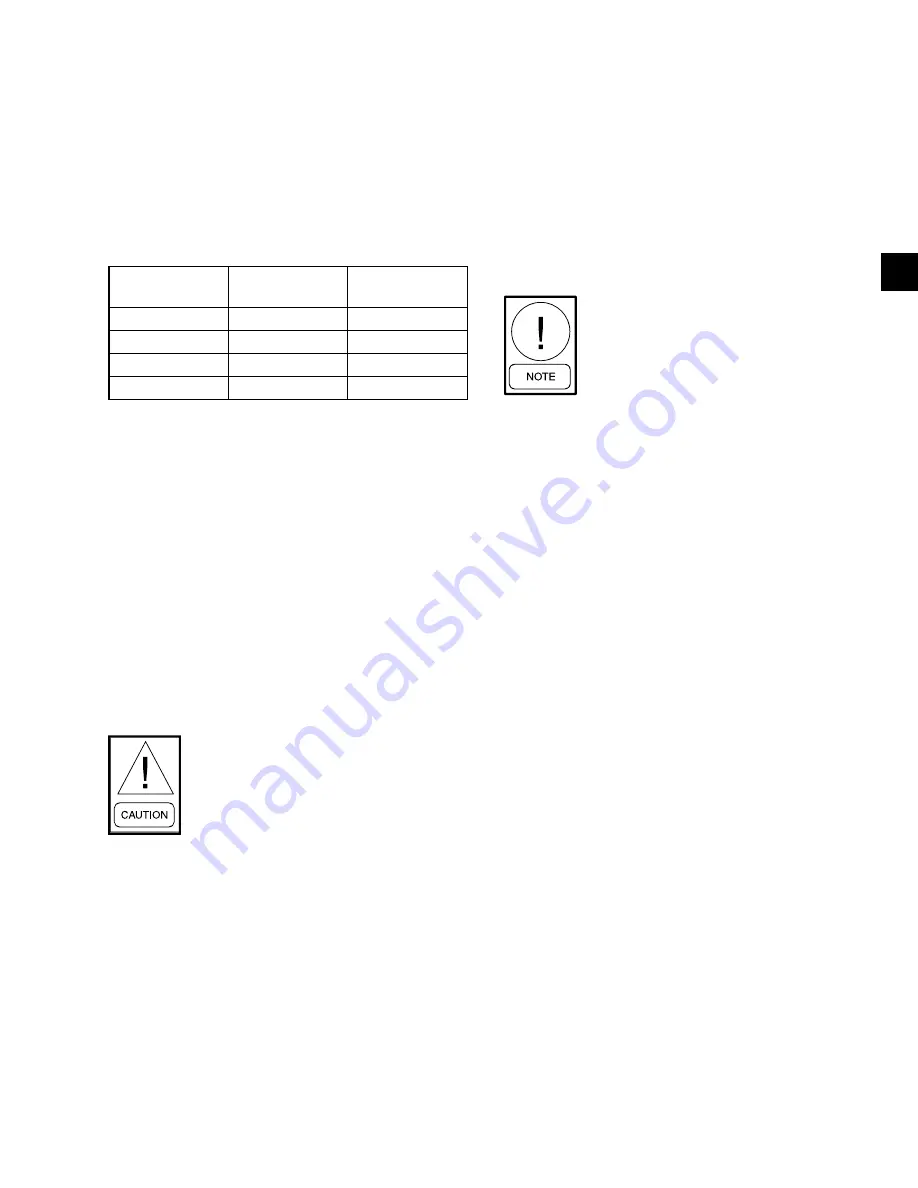

Mode

Control

Source

Min. Access

Level Req'd.

Auto

Local/Remote

View

Manual

Local/Remote

Operator

Repair

Local/Remote

Service

Maintenance

Local/Remote

Operator

The YIA purge system will collect any non-condensables

in the absorber section and store them in a unit mounted

purge tank. At a predetermined purge tank pressure, the

non-condensables will be expelled to the atmosphere by

a unit mounted purge pump. The YIA auto-purge will

also monitor, record and trend the amount of purges in

any given time.

Manual Purge

It may be necessary to manually purge the unit mounted

purge tank. The manual mode allows the operator to

perform this function. The manual purge can be per-

formed from the OptiView control panel independent

of unit operation. The pump can be turned on in either

the Operator or Service modes.

Before initiating a manual purge, VP2

must be opened and VP4 closed.

From the HOME screen select the PURGE key to

navigate to the Purge Screen. Select MAN/AUTO so the

purge field box displays "MANUAL". Press the "ON"

key and the purge pump will operate for 2 to 20 minutes

depending on the duration of the Purge Warm-up setpoint

(default is 2 minutes). If the purge pump was operated

in the past 50 minutes, the purge warm-up will be 2

minutes. Purge pump solenoid valve (8SOL) and purge

tank solenoid valve (7SOL) will be closed at this time.

After the pre-programmed purge warm-up period has

timed out the purge pump solenoid valve (8SOL) will

begin to open and a 1 minute timer will initiate. After the

1 minute timeout, the pressure at purge pump pressure

transducer (PT3) must be equal to or less than 15mm

Hg Abs. If not, the purge pump will continue to run for

an additional minute. If during this additional minute,

the pressure at PT3 reaches 15mm Hg Abs or less, purge

tank solenoid (7SOL) will open. If not, purge pump

solenoid valve (8SOL) will close and the purge pump

continues to run for 65 seconds. This allows time for

purge pump solenoid valve (8SOL) to fully close. The

panel will display a warning message that is further

explained in the Messages Section of this manual.

During the 65 second pump shut-off

delay, manual turn OFF of the purge

pump is prevented.

If at anytime during the manual purge process, the purge

pump pressure at PT3 or purge tank pressure (PT4)

reaches 100mm Hg Abs or higher, both the purge pump

solenoid valve (8SOL) and purge tank solenoid valve

(7SOL) will close. The purge pump will run for another

65 seconds then shutdown and the panel will display a

warning message that is further explained in the Mes-

sages Section of this manual.

Once purge tank solenoid valve (7SOL) is opened,

non-condensables stored in the Purge Tank will be

expelled to the Atmosphere by the Purge Pump. The

OptiView logic monitors this process and if a decrease

in pressure at the Purge Tank (PT4) is NOT seen every

6 seconds, the panel will initiate a purge failure.

A warning message will be displayed (further explained

in the Message Section of this manual) and both Purge

Tank Solenoid Valve (7SOL) and the Purge Pump

Motorized Ball Valve (8SOL) will close and the Purge

Pump will run for an additional 65 seconds before shut

-

ting off.

The Manual Purge will continue until Purge Tank Trans

-

ducer (PT4) reads 20mmHg Abs. At that time the manual

purge will initiate a normal shutdown by closing Purge

Tank Solenoid (7SOL) and Purge Pump motorized Ball

Valve (8SOL). The Purge Pump will continue to operate

for a post purge oil clean-up for 10 minutes.

After the manual purging is finished, press the "PURGE

PUMP" key to activate purge pump field then press

the "OFF" key to shut off the pump. The pump will

continue to run for an additional 10 minutes for a post

purge clean-up.