035-17480-000 Rev. A (800)

Unitary Products Group

11

COMBUSTION AIR AND VENT SYSTEM

1.

Two-pipe with a sealed combustion intake/vent system

using outdoor combustion air.

2.

Single pipe vent system using combustion air from the

area surrounding the furnace.

3.

Two-pipe intake/vent system using combustion air from a

ventilated attic space and a vent pipe to the outside.

Be sure to follow the appropriate venting section details,

related information and limitations for your type of installation.

METHOD ONE: TWO PIPE SEALED COMBUSTION

AIR & VENT SYSTEM

COMBUSTION AIR INTAKE/VENT CONNECTIONS

This type installation requires outdoor combustion air. Two

separate, properly-sized pipes must be used. One bringing

air from the outdoors to the furnace combustion air intake col-

lar on the burner box, and a second pipe from the furnace

vent connection (top right of unit) back to the outdoors. Refer

to Figure 9.

The intake/vent should be located either through the wall

(horizontal or side vent) or through the roof (vertical vent).

Care should be taken to locate side vented systems where

trees or shrubs will not block or restrict supply air from enter-

ing or combustion products from leaving the terminal.

Also, the terminal assembly should be located as far as pos-

sible from a swimming pool or a location where swimming

pool chemicals might be stored. Be sure the terminal assem-

bly follows the outdoor clearances listed in Table 2 for U.S.

installations. In Canada, refer to CAN/CGA-B149.1 or.2

Installation Code (latest edition-Venting Systems and Air

Supply).

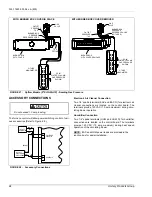

COMBUSTION AIR/VENT PIPE SIZING

To select the proper size piping for combustion air intake and

venting, refer to Table 3. The size will be determined by a

combination of furnace model, total length of run, and the

number of elbows required. The following rules must also be

observed.Long radius elbows are required for all units.

1.

Long radius elbows are required for all units.

2.

Elbows are assumed to be 90 degrees. Two 45 degree

elbows count as one 90 degree elbow.

3.

Elbow count refers to combustion air piping and vent pip-

ing separately. For example, if the table allows for 5

elbows, this will allow a maximum of 5 elbows in the

combustion air piping and a maximum of 5 elbows in the

vent piping.

4.

Three vent terminal elbows (two for vent pipe and one for

air intake pipe) are already accounted for and should not

be counted in the allowable total indicated in the table

(see vent termination section). These parts are shown

shaded.

5.

Combustion air and vent piping must be of the same

diameter.

6.

All combustion air/vent pipe and fittings must conform to

American National Standards Institute (ANSI) standards

and American Society for Testing and Materials (ASTM)

standards D1785 (Schedule 40 PVC), D2665 (PVC-

DWV), F891 (PVC-DWV Cellular Core). D2241 (SDR-21

and SDR-26 PVC), D2261 (ABS-DWV), or F628 (Sched-

ule 40 ABS. Pipe cement and primer must conform to

ASTM Standards D2564 (PVC) or D2235 (ABS).

7.

The use of flexible connectors or no hub connectors in

the vent system is not allowed. This type connection is

allowed in the combustion air pipe near the furnace for

air conditioning coil accessibility.

This furnace is certified to be installed with one of

three possible intake/vent configurations.

Furnace Intake / Vent Connection Size (All Models)

40 - 100 MBH

120 - 140 MBH

Intake

2”

3"

Vent

2”

2"

*

*.

Vent must be increased to 3" on this model.

Note 1:Any vent pipe size change must be made out-

side furnace casing in a vertical pipe section

to allow proper drainage of condensate.

Note 2: An offset using two 45 degree elbows will be

required for plenum clearance when the vent

is increased to 3”.

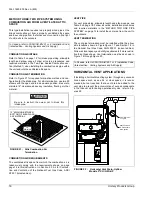

FIGURE 9 :

Upflow Air Intake/vent Locations

(Models P*XU/G9D-UP)

M

P

C

1

3

2

O

F

F

O

N

OMBUSTION AIR PIPE

PASSES THROUGH TOP PANEL

CONNECTS TO COLLAR

ON TOP OF BURNER BOX

VENT PIPE

CEMENTS

INTO SOCKET JUST

UNDER TOP PANEL