035-19650-001 Rev. C (0404)

Unitary Products Group

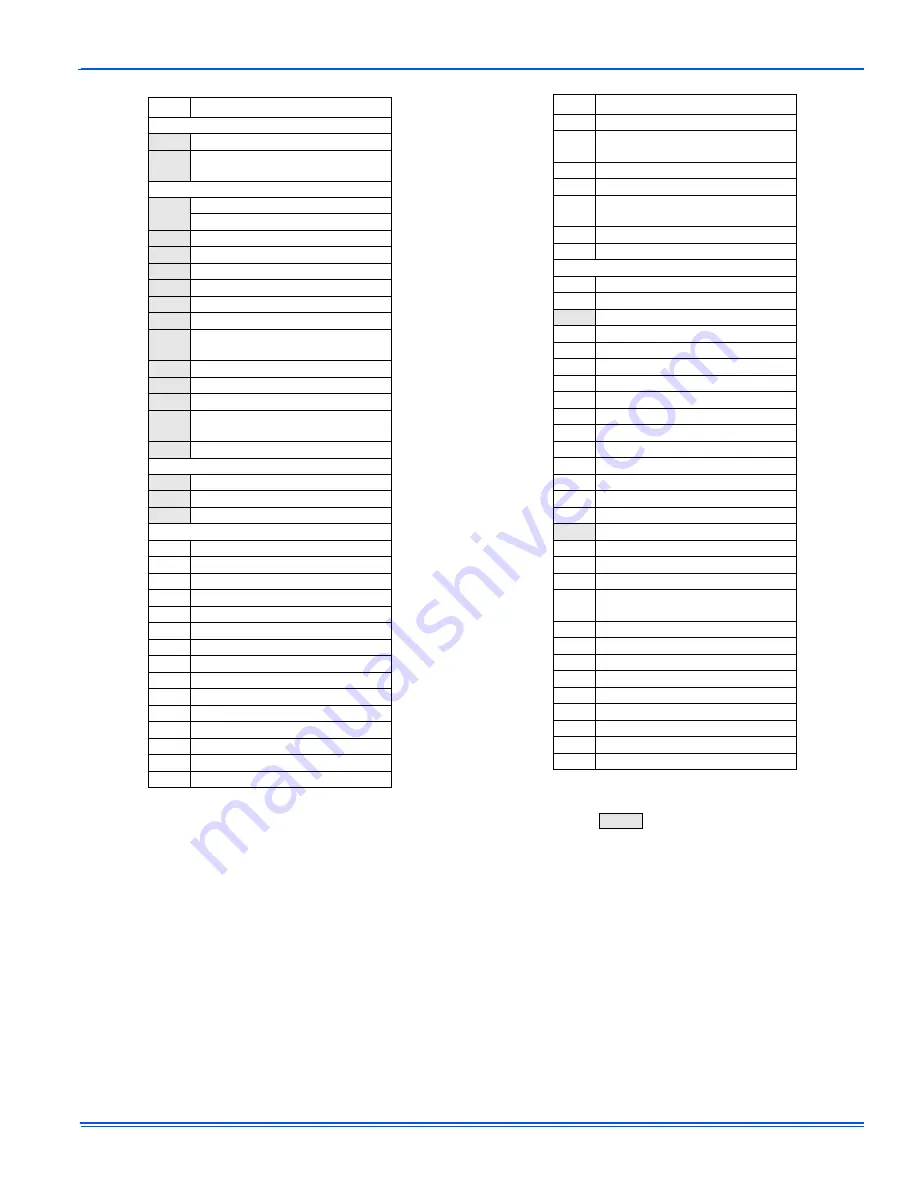

11

ITEM

DESCRIPTION

MOTOR

1

MOTOR,

DIRECT DRIVE BLOWER

2

MOTOR,VENTOR ASS’Y

MOTOR,VENTOR ASS’Y

ELECTRICAL

3

CAPACITOR (7.5MFD/370V)

CAPACITOR (10 MFD/370V)

4

CAPACITOR, VENTOR

(4MFD/370V)

5

CONTROL, HIGH LIMIT

6

CONTROL,

FLAME ROLL OUT

7

CONTROL,FURNACE

8

IGNITOR

9

SENSOR, FLAME

10

SWITCH, AIR PRESSURE [LP]

SWITCH, AIR PRESSURE [LP]

11

TIMER, 2 STAGE DELAY

12

SWITCH, DOOR

13

TRANSFORMER

14

VALVE, GAS

VALVE, GAS

14A

FUSE

AIR MOVING

15

CUTOFF,BLOWER

16

HOUSING, BLOWER

17

WHEEL, BLOWER

FABRICATED PARTS

18

BAFFLE, AIR (LH Recoup.Coil)

19

BAFFLE, AIR (RH Recoup.Coil)

20

BURNER, MAIN GAS

21

COIL,

SECONDARY HEAT EXCHANGER

22

DECK, BLOWER (Rear)

23

DECK, FRONT

24

HEAT EXCHANGER ASS’Y

(Primary)

25

MANIFOLD, GAS

26

PAN, BASE

27

PAN, CONDENSATE

28

PANEL, BURNER BOX (Bottom)

29

PANEL, BURNER BOX (Front)

30

WRAPPER, BURNER BOX

31

CHANNEL, TOE PLATE

32

COVER, HEAT EXCHANGER

33

PANEL, FRONT (Blower)

34

PANEL, FRONT (Burner)

PANEL, FRONT (Burner)

35

PANEL, TOP

36

SUPPORT, BURNER

37

WRAPPER, CABINET (Insulated)

WRAPPER, CABINET (Insulated)

38

PANEL, VESTIBULE (Lower)

39

PLUG, WINDOW, CLEAR - .875”

MISCELLANEOUS

40

CLIP

,

FILTER RETAINER (2 Req’d)

41

COLLAR, AIR INTAKE

(Burner Box)

42

FILTER, AIR (2 Req’d)

FILTER SIZE

43

GASKET, AIR INTAKE

44

GASKET,

COMBUSTION BLOWER

45

GASKET, CONDENSATE PAN

46

GASKET, BURNER BOX

47

GASKET,

BURN BOX TO VEST PANEL

48

GROMMET, MANIFOLD SEAL

49

PLUG, WINDOW,CLEAR - 1.5”

50

HANDLE, DOOR

51

ISOLATOR, TUBE (3 Req’d)

52

ISOLATOR, WASHER (3 Req’d)

53

ISOLATOR, SLEEVE (3 Req’d)

54

MOUNT, MOTOR

55

ORIFICE, BURNER

(Natural #45)

56

57

RETAINER, FILTER

58

TRAP, CONDENSATE

TRAP, CONDENSATE

59

WIRING DIAGRAM

60

TUBE, DRAIN RAIN GUTTER

61

TUBE, DRAIN

CONDENSATE PAN

62

TUBE, DRAIN

CONDENSATE TRAP

63

BRACKET, IGNITOR

64

TUBE,

CONDENSATE DRAIN

65

PIPE EXHAUST VENT

66

HARNESS, WIRING

67

TUBING, SILICONE

ITEM

DESCRIPTION

Major components and suggested stocking items are shown with shaded item number.