035-19650-001 Rev. C (0404)

6

Unitary Products Group

6.

1st and 2nd Stage satisfied simultaneously

• Both stages of the Gas Valve are de-energized.

• Flame Rectification is lost.

• The Inducer and Hum relays are de-energized after a 15-second

post purge.

• 30 seconds later the Control shifts the Blower from Heat High to

Heat Low.

• After the Blower-Off Delay Circuit is satisfied, the Blower and

EAC are de-energized.

7.

Manual Fan Operation

• With the thermostat in the Fan On position, a circuit is completed

between R and G of the Control.

• The Heat Low and EAC relays are energized by the Control.

8.

Call for Cooling

• The thermostat closes two circuits R to Y and R to G. Since the

Outdoor Unit is connected to Y and C at the Control, it is ener-

gized.

• The Cool and EAC relays are energized by the Control.

• A Blower-Off Delay Timing Circuit is energized by the call on Y.

9.

Cooling call satisfied

• The thermostat opens the R to Y and R to G circuits.

• The Outdoor Unit is de-energized.

• The 60-second, Blower-Off Delay, timing circuit is initiated.

• After 60 seconds, the Cool and EAC relays are de-energized.

Heating Indoor Fan Off Delay

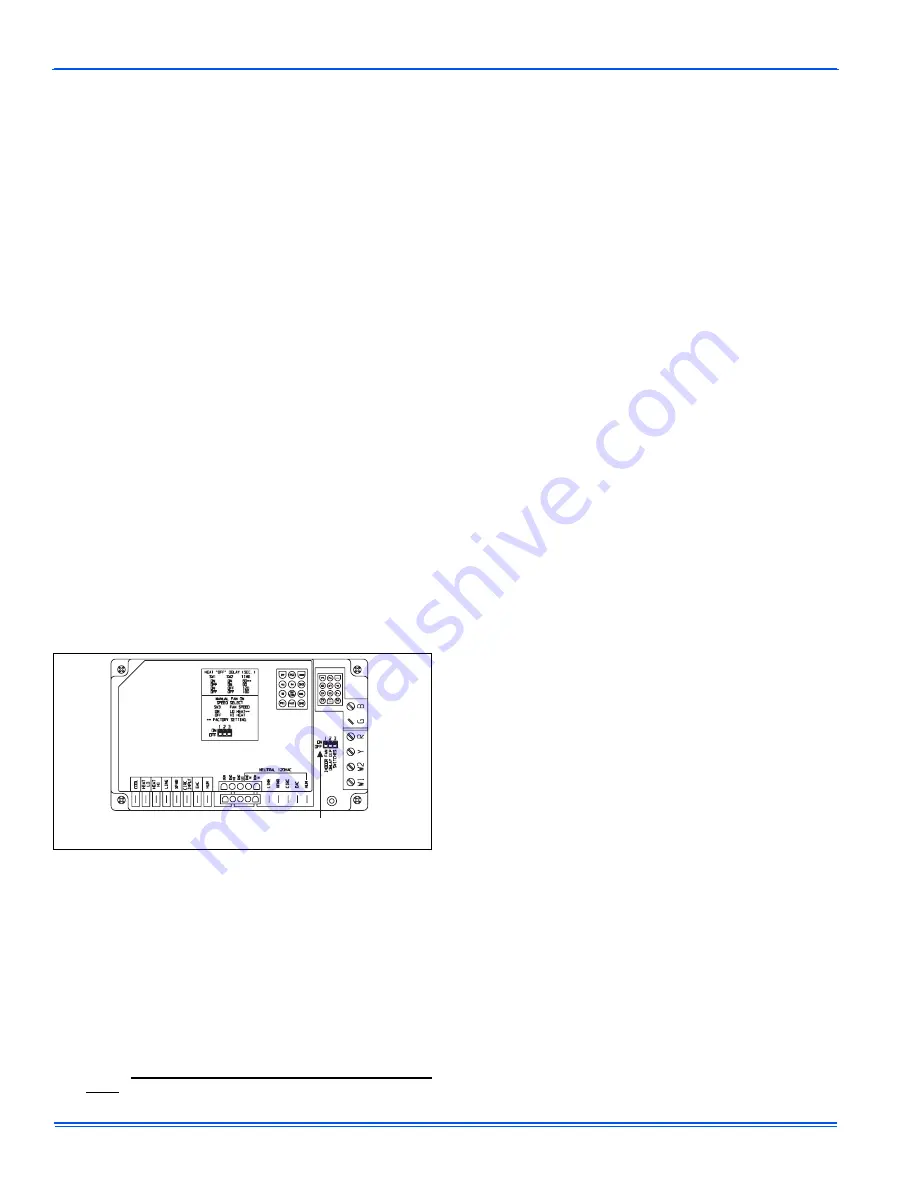

Changing the dipswitches on the Integrated Control can change the

indoor fan “OFF” time delay. The dipswitches are located above the

thermostat terminals. Refer to Figure 8 for the dipswitch settings to

obtain the desired fan OFF delay. The blower off delay must be long

enough to adequately cool the furnace, but not so long that cold air is

blown into the living space.

The blower on delay is fixed at 30 seconds and cannot be adjusted.

The continuous fan speed dipswitch (switch # 3 on the Integrated Con-

trol) does not function on variable speed models. Dipswitch # 3 should

be left in the off position.

Continuous Blower:

There are two modes of continuous blower operation.

•

Mode One:

The blower is controlled directly through the blower

motor. In the first mode, when the thermostat fan-switch is set to

the ON position a circuit is completed between terminals “R” and

“G” of the thermostat. The continuous fan speed will be 63% of

the high cool speed. If more air is desirable the green wire

labeled (G Cool Speed) may be connected to the “G” terminal of

the ignition control to achieve HIGH COOL speed (DIP switch

number 3 on the ignition control must be in the OFF position).

•

Mode Two:

The blower is controlled through the ignition control.

This configuration is used with multi-speed direct drive PSC

motors.

Do not use this configuration with a variable speed

motor.

Refer to Heating Indoor Fan Off Delay for Fan ON / OFF

Delays.

The air cleaner and the blower motor are energized through the ignition

control or directly through the motor.

DIRECT DRIVE BLOWER MOTOR

A failed PSC motor should always be replaced with a PSC motor suit-

able for the furnace model being serviced. Follow the procedure below

to replace the motor.

Removal of the Variable Speed Blower Motor Assembly:

The procedure for removing the variable speed blower assembly:

1.

Disconnect the electrical supply to the furnace and remove the

access doors.

2.

Remove blower assembly mounting screws and slide the blower

assembly out of the slots in the deck. If the two shipping screws

were not previously removed, also remove and discard these two

screws located on each front corner of the blower assembly.

3.

Loosen the blower wheel set screw that secures the blower wheel

to the blower motor shaft.

4.

Remove the motor mount bolts.

5.

Slide the variable speed motor out of the blower housing.

Reassembly of the Variable Speed Blower Motor Assembly:

1.

Slide the new variable speed motor in to the blower housing. Make

sure you line up the flat side on the motor shaft with the setscrew

on the hub in the center of the blower wheel.

2.

Install the motor mount bolts in to the fan housing.

3.

Center the indoor fan wheel in the fan housing and tighten the

blower wheel set screw on the flat side the blower motor shaft.

4.

Reinstall blower assembly mounting screws and slide the blower

assembly back in the slots in the deck. Do not reinstall the two

shipping screws were removed.

5.

Install the access doors.

6.

Restore power to the furnace and verify operation.

INSTALLATION OF PSC MOTOR:

The motor speed tap wires are connected to the 1/4" quick connect ter-

minal on the Integrated Control using the black jumper wire that is

secured to the wire harness inside the burner compartment and is

marked “PSC Motor”. Follow the instructions below to properly install

the PSC motor.

1.

Install the PSC direct drive motor into motor mount.

2.

Slide motor in motor mount insuring there is no interference

between moving and stationary parts. Position wire leads down-

ward. Tighten motor mount band screw to 30 in. lbs.

3.

Center the blower wheel in the blower housing and align the shaft

flat with the blower wheel set screw. Tighten setscrew to 30 in. lbs.

4.

Replace blower assembly and fasten with 5 screws

5.

Strap motor capacitor to electric panel. Refer to Table 2 for proper

capacitor selection.

6.

Fasten electric panel to blower housing.

7.

Remove red wire from circuit input terminal. Plug jumper wire

(attach to motor power harness) on 120-volt line terminal on igni-

tion control and jumper to circuit Input. Connect brown door switch

wire to jumper.

8.

Connect white main harness lead to Line neutral.

9.

Connect motor leads to cool, heat lo and heat high per electrical

wire diagram table in the Installation manual.

10. Connect brown capacitor leads from motor to capacitor and cover

terminals with boot supplied.

11.

The motor ground (green) wire is secured to the right front of the

blower mounting plate with a screw.

12. Restore power to the furnace and verify operation.

FIGURE 7:

White Rodgers Intergrated Control

INDOOR FAN OFF

DELAY DIP SWITCHES