035-19650-001 Rev. C (0404)

Unitary Products Group

7

Hot Surface Ignition System

FURNACE CLEANING SECTION

NOTE:

The cleaning operations listed below must be performed only by

a qualified service agency.

Burner Removal/Cleaning

The main burners should be checked periodically for dirt accumulation.

If cleaning is required, follow this procedure:

1.

Turn off the electrical power to the unit.

2.

Turn off the gas supply at the external manual shut-off valve and

loosen the ground union joint.

3.

Remove the burner door and remove the burner box cover.

4.

Disconnect wires from flame sensor, rollout switch and HSI igniter.

Remove igniter carefully, as it is easily broken.

5.

Remove the screws that hold the burner box assembly to the vest

panel and remove the assembly.

6.

Remove burners from the burner assembly.

7.

Burners may be cleaned by rinsing in hot water.

8.

Reassemble the burners in the reverse order.

Cleaning the Heat Exchanger

1.

Turn off the electrical power to the unit.

2.

Turn off the gas supply at the external manual shut-off valve and

loosen the ground union joint.

3.

Remove the upper access panel and remove the burner box

cover.

4.

Disconnect wires from flame sensor, rollout switch and HSI igniter.

Remove igniter carefully, as it is easily broken.

5.

Remove the screws that hold the burner box assembly to the vest

panel and remove the assembly.

6.

Remove burners from the burner assembly.

7.

Remove the upper cover plate at the top of the furnace. Remove

the internal baffle.

8.

The upper portion of the heat exchanger is now exposed.

9.

With a long flexible wire brush, clean inside each tube at both the

top and bottom. The brush must pass around the rear heat

exchanger tubes and then vacuum loose the scale and dirt from

each tube.

10. Clean - vacuum all burners.

11.

Replace all components in reverse order. Reconnect all wiring.

12. Restore electrical power and gas supply to the furnace.

13. Check furnace operation.

Cleaning the Secondary Heat Exchanger

1.

Follow steps 1 - 8 under cleaning the Heat Exchanger.

2.

Remove the vent piping from the vent blower housing. Disconnect

the drain lines from the vent blower housing and from the conden-

sate drain pan. Remove the vent blower housing blower and the

condensate pan. The turbulators can then be gently removed from

the secondary heat exchanger.

3.

Using a stiff wire brush, remove the loose scale or soot from each

tube.

4.

Vacuum the secondary heat exchanger.

5.

Finish the cleaning procedure by following steps 11 thru 13 under

cleaning the Heat Exchanger.

TROUBLESHOOTING

The following visual checks should be made before troubleshooting:

1.

Check to see that the power to the furnace and the ignition control

module is ON.

2.

The manual shut-off valves in the gas line to the furnace must be

open.

3.

Make sure all wiring connections are secure.

4.

Review the sequence of operation. Start the system by setting the

thermostat above the room temperature. Observe the system’s

response. Then use the troubleshooting section in this manual to

check the system’s operation.

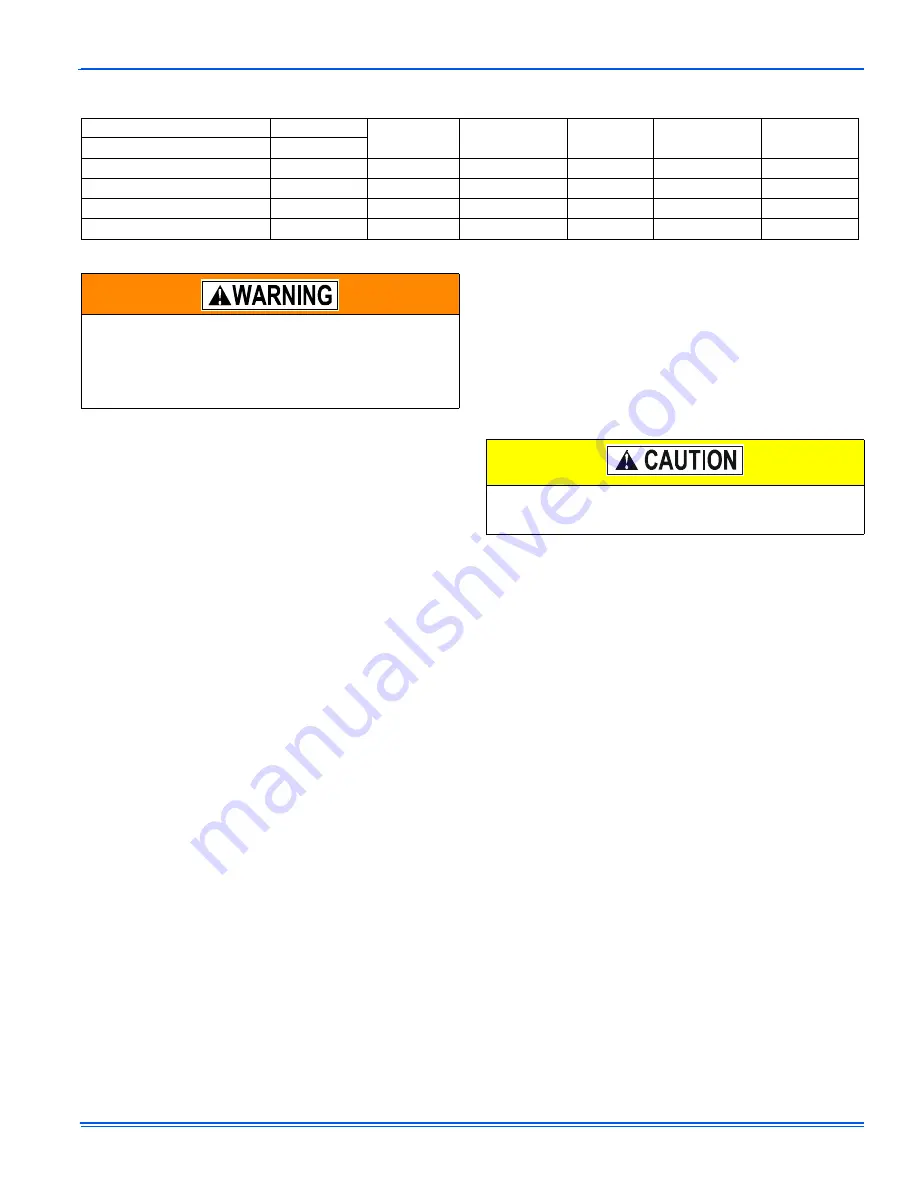

TABLE 2:

Replacement PSC Motor / Capacitor Information

High Fire Inputs

Airflow

Cabinet Size

Motor

Part Number

Motor

Horsepower

Capacitor

Part Number

Capacitor

Rating

BTU/H (kW)

CFM (m³)

60,000 (17.6)

1,200 (33.98)

B

024-23271-000

1/2

024-20045-000

7.5 f

80,000 (23.4)

1,600 (45.31)

C

024-26002-000

3/4

024-20046-000

10.0 f

100,000 (29.3)

2,000 (56.63)

C

024-23288-001

1.0

024-20446-000

15.0 f

120,000 (35.1)

2,000 (56.63)

D

024-23238-001

1.0

024-20446-000

15.0 f

HOT SURFACE IGNITION SYSTEM

Do not attempt to light this furnace by hand (with a

match or any other means). There may be a potential

shock hazard from the components of the hot surface

ignition system. The furnace can only be lit automatically

by its hot surface ignition system.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and danger-

ous operation. Verify proper operation after servicing.