035-19650-001 Rev. C (0404)

Unitary Products Group

9

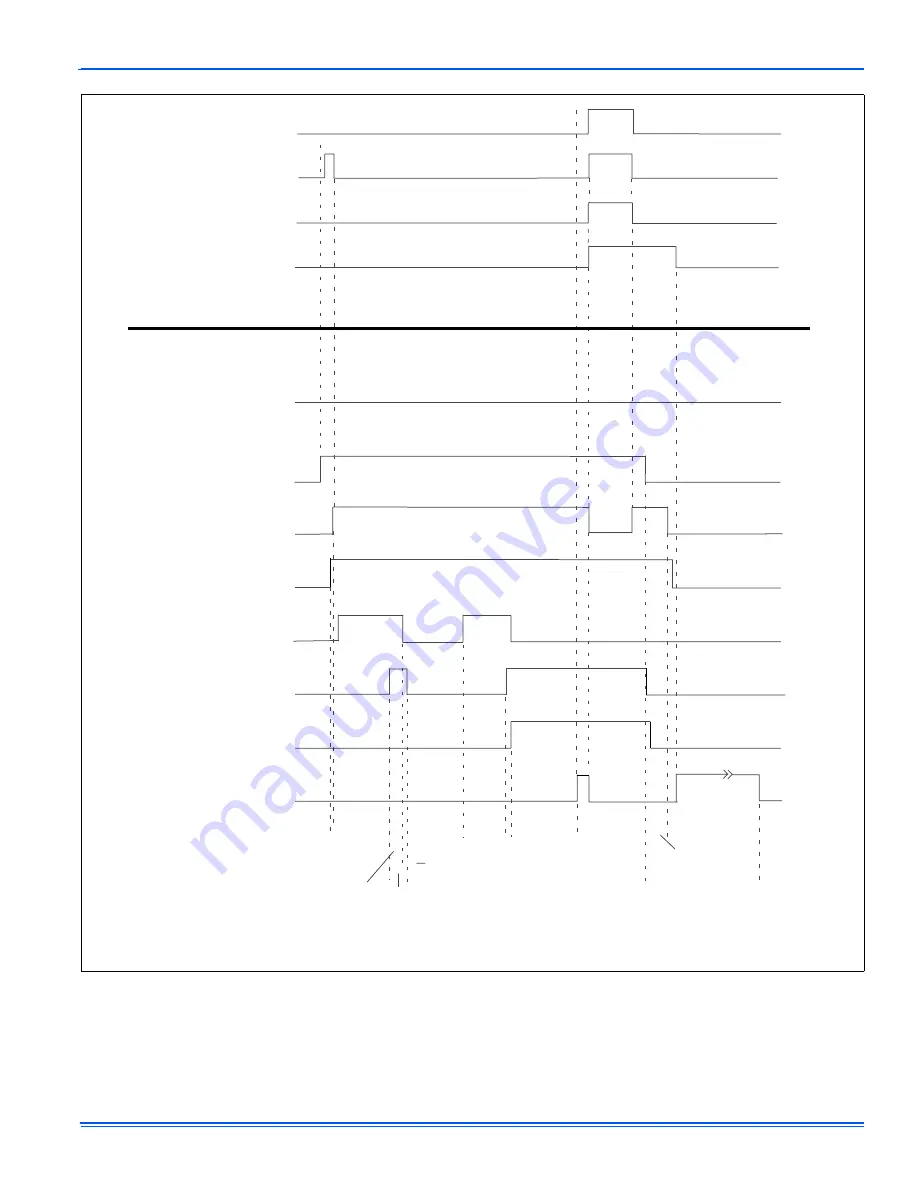

FIGURE 8:

Furnace Control Event Schedule

W2 SIGNAL

ON

CLOSED

OPEN

OPEN

CLOSED

ABSENT

PRESENT

HIGH INDUCER

HIGH STAGE PRESSURE

SWITCH AND 2ND STAGE

MAIN VALVE

CIRCULATOR HIGH

HEAT SPEED

2ND STAGE

CALL HIGH HEAT AFTER LOW

HEAT IS ESTABLISHED

HIGH

HEAT

OFF

DELAY

30 SEC.

HIGH LIMIT

W1 SIGNAL

LOW

INDUCER

LOW STAGE

PRESSURE

SWITCH

HSI

1ST STAGE

MAIN VALVE

FLAME

SENSE

LOW CIRCULATOR

HEAT SPEED

1ST STAGE

LOW PRESSURE

SWITCH CLOSE

RECOGNITION

HSI

WARM

UP

17 SEC.

IGNITION

ACTIVATION

PERIOD

4 SEC.

TRIAL FOR

IGNITION

7 SEC.

INTER-

PURGE

60 SEC.

HSI

WARM

UP

27 SEC.

IGNITION

DEACTIVATION

PERIOD

3 SEC.

HEAT FAN

DELAY ON

30 SEC.

BURN

TIME

POST

PURGE

15 SEC.

HEAT FAN DELAY OFF

SELECTABLE

60,90,120,180 SEC.

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

NOTE:

1. THIS DIAGRAM SHOWS TWO IGNITION ATTEMPTS

2. TIMING LENGTHS ARE NOT TO SCALE