4. With the furnace in operation, paint the pipe joints and

valve gasket lines with a rich soap and water solution.

Bubbles indicate a gas leak. Take appropriate steps to stop

the leaks. If the leak persists, replace the component.

WARNING: DO NOT omit this test! NEVER use a flame to

check for gas leaks.

CHECKING GAS INPUT

1. Turn off all other gas appliances connected to gas meter.

2. With the furnace turned on, measure the time needed for

one revolution of the hand on the smallest dial on the

meter. A typical domestic gas meter usually has a 1/2 or 1

cubic foot test dial.

3. Using the number of seconds for each revolution and the

size of the test dial increment, find the cubic feet of gas

consumed per hour from Table 4.

NOTE: To find the Btuh input, multiply the number of cubic feet

of gas consumed per hour by the BTU content of the gas

in your particular locality. Contract your gas company for

this information, as it varies widely from city to city.

EXAMPLE: It is found by measurement that it takes 26 seconds

for the hand to turn on the 1 cubic foot dial to make a revolution

with only a 120,000 Btuh furnace running. Using this informa-

tion, locate 26 seconds in the first column of Table 3.

Read across to the column headed "1 Cubic Foot" where you

will see that 138 cubic feet of gas per hour are consumed by

the furnace at that rate. Multiply 138 by 850 (the BTU rating of

the gas obtained from the local gas company). The result is

117,300 Btuh, which is close to the 120,000 Btuh rating of the

furnace.

If the actual input is not within

±

2% of the furnace rating, with

allowance being made for the permissible range of the regula-

tor setting (0.3 inches W.C.), replace the orifice spuds with

spuds of the proper size.

CAUTION: Be sure to relight any gas appliances that were

turned off at the start of this input check.

ADJUSTMENT OF MANIFOLD GAS PRESSURE

1. Turn gas off at main gas valve. Remove 1/8" plug in the main

gas valve body and install proper manometer tube adapter

fitting. Connect line from gas valve tap to manometer.

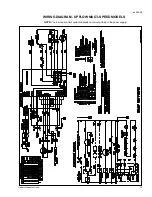

2. Refer to Figure 14 for location of pressure regulator adjust-

ment cap and screw on main gas valve.

NOTE: The screw-off cap for the pressure regulator must be

removed entirely to gain access to the adjustment screw.

WARNING: The cap must be replaced in order for the furnace

to operate properly.

3. Turn gas and electrical supplies ON. Start furnace and

observe manifold pressure on manifold.

4. Adjust manifold pressure by adjusting gas valve regulator

screw.

If gas valve regulator is turned in, or clockwise, manifold

pressure is increased. If screw is turned out, or counterwise,

manifold pressure will decrease.

WARNING: The manifold pressure must be checked with the

screw-off cap in place on the pressure regulator.

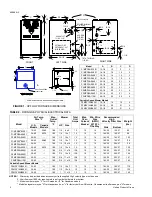

Natural

Gas 3.5"

W.C.

Propane

(LP) 10.0"

W.C.

FIGURE 14 - GAS VALVES

TOP

-

WHITE-RODGERS

36E97

BOTTOM

-

HONEYWELL

VR8205

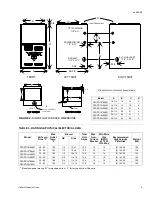

Seconds for

One Revolution

Size of Test Dial

1/2 cubic foot

1 cubic foot

10

180

360

12

150

300

14

129

257

16

113

225

18

100

200

20

90

180

22

82

164

24

75

150

26

69

138

28

64

129

30

60

120

32

56

113

34

53

106

36

50

100

38

47

95

40

45

90

42

43

86

44

41

82

46

39

78

48

37

75

50

36

72

52

35

69

54

34

67

56

32

64

58

31

62

60

30

60

TABLE 4 - GAS RATE (Cubic Feet Per Hour)

650.69-N3

12

Unitary Products Group