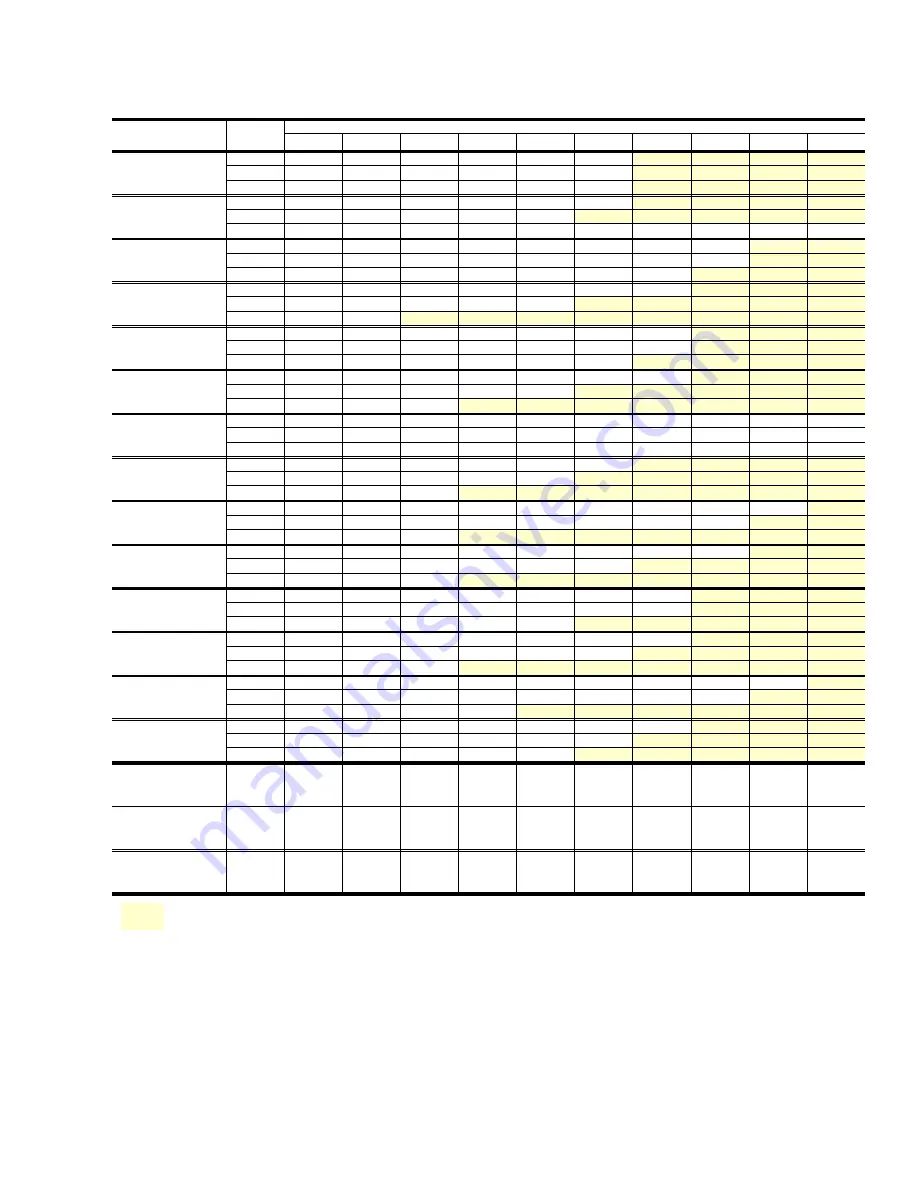

BLOWER PERFORMANCE - UPFLOW/HORIZONTAL - CFM (Includes Filter)

MODEL

SPEED

TAP

EXTERNAL STATIC PRESSURE, INCHES W.C.

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

P2MPD08N03201

(See Note 1)

HIGH

1150

1090

1021

945

877

791

670

458

—

—

MED

1027

971

930

862

790

714

597

411

—

—

LOW

846

817

782

726

673

608

500

317

—

—

P2MPD08N04801

(See Note 3)

HIGH

998

965

934

878

827

769

665

576

489

323

MED

890

858

824

775

741

660

584

504

—

—

LOW

—

—

—

—

—

—

—

—

—

—

P2MPD12N04801

(See Note 2)

HIGH

1548

1480

1396

1312

1270

1126

1029

908

736

563

MED

1275

1221

1180

1152

1080

1016

922

807

657

482

LOW

—

1055

1050

1034

998

960

888

773

645

446

P2MP12N06401

(See Note 2)

HIGH

1605

1538

1427

1331

1284

1178

1080

978

815

619

MED

1172

1195

1140

1102

1076

985

908

822

682

5663

LOW

—

—

967

932

925

885

851

763

630

—

P2MPD16N06401

(See Note 3)

HIGH

1967

1884

1795

1697

1605

1477

1340

1167

986

799

MED

1822

1758

1673

1592

1512

1399

1256

1107

917

742

LOW

—

—

1440

1383

1330

1240

1142

986

841

702

P2MPN14N08001

(See Note 3)

HIGH

1861

1798

1698

1584

1494

1364

1258

1087

898

756

MED

1569

1503

1438

1375

1277

1182

1071

928

772

643

LOW

—

1295

1270

1198

1156

1063

966

857

725

616

P2MPD20N08001

(See Notes 4, 7)

HIGH

2380

2318

2243

2195

2107

2017

1944

1811

1703

1583

MED

1989

1976

1967

1949

1907

1832

1755

1680

1566

1477

LOW

—

—

1585

1570

1527

1502

1447

1398

1333

1248

P2MPD16N09601

(See Note 4)

HIGH

2117

2023

1920

1821

1731

1587

1459

1302

1045

818

MED

1905

1821

1743

1649

1563

1465

1332

1168

957

643

LOW

1546

1532

1495

1424

1357

1268

1155

1000

840

663

P2MPD20N09601

(See Notes 5, 7)

HIGH

—

2367

2342

2270

2198

2110

2004

1913

1797

1581

MED

2027

1986

1945

1917

1877

1820

1763

1653

1558

1445

LOW

—

—

—

1349

1327

1312

1281

1233

1150

1078

P2MPD20N11201

(See Notes 6, 7)

HIGH

2204

2154

2081

2055

2002

1933

1843

1706

1545

1409

MED

—

1805

1779

1758

1715

1656

1579

1507

1395

1292

LOW

—

—

—

1451

1451

1423

1377

1284

1201

1095

P9MPD08N03201

(See Note 1)

HIGH

1175

1020

995

890

835

740

685

—

—

—

MED

950

920

885

810

710

650

605

—

—

—

LOW

625

605

595

580

550

—

—

—

—

—

P9MPD08N04801

(See Note 3)

HIGH

998

965

934

878

827

769

665

576

489

—

MED

890

858

824

775

741

660

584

504

—

—

LOW

684

650

610

506

521

469

—

—

—

—

P9MPD12N06401

(See Note 2)

HIGH

1475

1437

1395

1325

1235

1150

1030

915

755

—

MED

1220

1195

1130

1085

1040

965

870

763

—

—

LOW

805

795

765

750

725

—

—

—

—

—

P9MPD14N08001

(See Note 3)

HIGH

1670

1620

1565

1485

1410

1305

1145

955

790

—

MED

1370

1355

1310

1265

1205

1125

975

865

—

—

LOW

1085

1060

1035

1005

995

925

—

—

—

—

P2MPV12N06401

1200**

CFM

SETTING

1200

1200

1200

1200

1200

1200

1200

1200

—

—

P2MPV14N08001

1400**

CFM

SETTING

1400

1400

1400

1400

1400

1400

1400

1400

1400

1400

P2MPV20N08001

(See Note 7)

2000**

CFM

SETTING

2000

2000

2000

2000

2000

2000

2000

2000

2000

—

These conditions are outside the recommended heating operating range.

Airlfow is expressed in standard cubic feet per minute.

Motor voltage at 115V

**

Other CFM settings are available.

Figures shown are for left side return air installation, except for the D20 units which must use both sides for applications over 1800

CFM. All units may use bottom only return, see correction factors listed in Notes 1-6.

NOTES:

1 - CFM shown x .90 5 - CFM shown x .91

2 - CFM shown x .98 6 - CFM shown x .96

3 - CFM shown x .97 7 - Air flow shown is with return air from both sides.

4 - CFM shown x .93 Use the derate factors for bottom only return

650.69-N3

Unitary Products Group

21